Custom Paper Packaging Tape for PVC Electrical Tape of Single and Double Colors

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape of Single and Double Colors

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape of Single and Double Colors

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape of Single and Double Colors

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape of Single and Double Colors

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

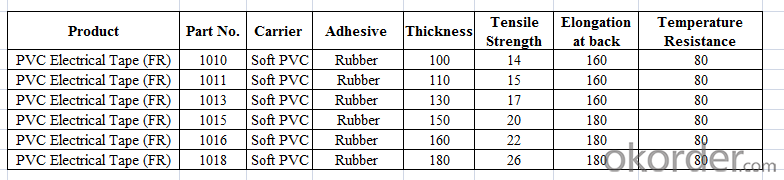

Technical Data of PVC Electrical Tape of Single and Double Colors

Product Show of PVC Electrical Tape of Single and Double Colors

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Can packaging tape be used for sealing foam?

- Yes, packaging tape can be used for sealing foam. Packaging tape is commonly used for sealing boxes and packages, but it can also be used effectively to seal foam. When using packaging tape to seal foam, it is important to ensure that the tape is securely adhered to the foam surface to create a tight seal. This can be achieved by applying pressure to the tape after it has been applied. Additionally, it is recommended to use a tape that is specifically designed for sealing foam, as these tapes often have stronger adhesive properties and are more resistant to temperature changes and moisture. Overall, packaging tape can be a convenient and effective option for sealing foam.

- Q: Can packaging tape be used for sealing packages with electronics or electrical components?

- Sealing packages containing electronics or electrical components with packaging tape is possible. However, it is essential to understand that not all packaging tapes are suitable for this purpose. To ensure the safety of the items, it is advised to opt for an anti-static or ESD-safe tape. These tapes are specifically crafted to shield sensitive electronic components from static electricity during transportation or handling. Using regular packaging tape lacking anti-static properties may expose the electronics to the risk of static discharge, potentially leading to damage or compromised performance. Therefore, it is crucial to carefully assess the specific requirements of the electronics being packaged and select an appropriate tape accordingly, guaranteeing their protection.

- Q: Can packaging tape be used for bundling items together?

- Absolutely, packaging tape is perfect for bundling various items together. It serves as a reliable means to firmly secure and hold multiple objects, particularly when engaged in shipping or relocating. Engineered to possess strength and dependability, packaging tape ensures a steadfast grip that effectively keeps items tightly bundled. Frequently employed for the purpose of bundling boxes, packages, or any other items necessitating cohesion during transportation or storage.

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Yes, packaging tape can be used for sealing plastic toolboxes. The strong adhesive on packaging tape can effectively seal the edges and seams of plastic toolboxes, providing a secure closure. However, it is important to consider the weight and durability of the items being stored in the toolbox, as packaging tape may not be as robust as specialized toolbox sealants or gaskets.

- Q: Can packaging tape be used in extreme temperatures?

- Yes, packaging tape can generally be used in extreme temperatures. However, the specific temperature range and the type of tape should be considered. Some packaging tapes are designed to withstand both high and low temperatures, ensuring their adhesive properties remain intact. It is recommended to check the manufacturer's instructions or consult with a professional to ensure the tape is suitable for the specific extreme temperature conditions.

- Q: What are the benefits of using double-sided packaging tape?

- Using double-sided packaging tape has several advantages. Firstly, it ensures a strong and secure bond between surfaces, making it perfect for packaging applications where contents need to stay in place during transit or storage. The tape creates a powerful adhesive bond, reducing the risk of items shifting or becoming damaged. Secondly, double-sided packaging tape is versatile and can be used for various purposes. It can seal boxes, attach labels or documents, and even mount lightweight objects. This versatility makes it valuable for personal and professional packaging needs. Additionally, double-sided packaging tape is easy to use. Unlike traditional tapes that require adhesive to be applied on both surfaces, double-sided tape already has adhesive on both sides, making it a convenient option. Simply peel off the backing and apply the tape to the desired surface, saving time and effort. Moreover, double-sided packaging tape provides a neat and clean appearance. As it is hidden between bonded surfaces, it creates a seamless look without any visible tape lines. This is especially useful when packaging gifts or products that require a professional and presentable appearance. Lastly, double-sided packaging tape is designed to be durable and long-lasting. It can withstand various environmental conditions, such as temperature changes, humidity, and exposure to moisture, without losing its adhesive properties. This ensures that your packaging remains intact and secure for an extended period of time. In conclusion, the benefits of using double-sided packaging tape include strong adhesion, versatility, ease of use, a clean appearance, and durability. Whether you are packaging items for personal or professional purposes, double-sided packaging tape provides a reliable and efficient solution.

- Q: How does packaging tape affect the weight of a package?

- The weight of a package is not directly influenced by packaging tape. Instead, it is determined by the contents within, including the item being shipped, any extra packaging materials, and the actual weight of the packaging. Packaging tape is utilized to secure the package's contents and guarantee their protection during transportation. Although the tape may have a slight weight, it is insignificant compared to the total weight of the package. As a result, the weight of a package is not significantly affected by the packaging tape.

- Q: What are the benefits of using tear-resistant packaging tape?

- There are several benefits of using tear-resistant packaging tape. Firstly, tear-resistant packaging tape provides enhanced security and protection to your packages during transit or storage. Its strong adhesive and tear-resistant material ensure that the tape remains intact and prevents any tampering or accidental tearing of the packaging. This helps to maintain the integrity of the contents and minimizes the risk of damage or loss. Secondly, tear-resistant packaging tape offers greater durability and longevity compared to regular packaging tapes. Its robust design and resistance to tearing make it ideal for packaging items that are heavy, have sharp edges, or are susceptible to rough handling. This ensures that the tape stays intact throughout the entire shipping process, reducing the need for re-taping or potential damage to the package. Additionally, tear-resistant packaging tape is often weather-resistant and can withstand various environmental conditions. It is designed to resist moisture, extreme temperatures, and UV exposure, making it suitable for long-distance shipping or storage in different climates. This prevents the tape from deteriorating or becoming weak, ensuring that your packages remain securely sealed and protected. Moreover, tear-resistant packaging tape is easy to use and provides a professional finish to your packages. Its strong adhesive enables it to bond quickly and securely to various surfaces, including cardboard, plastic, or metal. This ensures that the tape stays in place and does not unravel or loosen during transit. Furthermore, tear-resistant packaging tape is available in different sizes and colors, allowing you to customize your packaging and create a visually appealing presentation for your customers. In summary, the benefits of using tear-resistant packaging tape include enhanced security, increased durability, weather resistance, ease of use, and a professional appearance. By investing in tear-resistant packaging tape, you can ensure that your packages are well-protected, reduce the risk of damage or tampering, and enhance the overall shipping experience for both you and your customers.

- Q: Can packaging tape be used for other purposes besides packaging?

- Packaging tape is not limited to packaging; it can be utilized for various purposes. With its strong adhesive properties and durability, it serves a multitude of functions. For instance, it proves useful in household repairs like mending broken book spines or securing loose cables. Moreover, it finds its place in crafting projects, allowing the creation of temporary or permanent decorations, durable envelopes, and even makeshift labels or item organization. Additionally, it comes in handy for quick fixes, like sealing small leaks or cracks in pipes or containers until a more permanent solution is discovered. The versatility of packaging tape ensures its usefulness in diverse situations, making it an essential tool for any home or office, surpassing its initial purpose of packaging.

- Q: Can packaging tape be used for sealing plastic storage bags?

- Yes, packaging tape can be used for sealing plastic storage bags. It provides a strong adhesive bond that helps keep the bags securely sealed.

Send your message to us

Custom Paper Packaging Tape for PVC Electrical Tape of Single and Double Colors

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords