Custom Polypropylene Packaging Tape - PVC Electrical Insulation Tape New Material Good Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

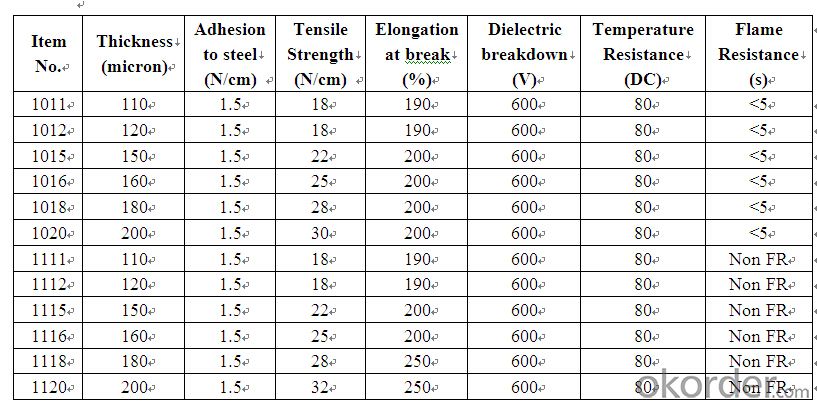

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Does packaging tape come with a dispenser?

- Packaging tape often comes accompanied by a dispenser, aiming to facilitate and optimize the application of the tape onto packages. The dispenser is usually equipped with a handle, granting you the ability to firmly grasp and manage the tape while sealing boxes or packages. This eliminates the necessity of manually cutting the tape, as well as prevents any entanglement or wastage. However, it is crucial to acknowledge that not all packaging tapes are bundled with a dispenser. Some tapes may require separate purchase, whereas others may be conveniently offered as a set, inclusive of the dispenser. It is always advisable to consult the product description or packaging for confirmation regarding the inclusion of a dispenser alongside the packaging tape.

- Q: How does packaging tape perform on high-friction surfaces?

- Packaging tape is specifically designed to stick to various surfaces, including those with high friction. The tape's ability to adhere to high-friction surfaces may vary depending on the specific type of tape and the surface it is applied to. In general, packaging tape has a strong adhesive that allows it to securely stick to surfaces, even those with high levels of friction. The tape's adhesive is formulated to provide excellent tackiness and bonding strength, ensuring that it remains in place and maintains its hold on high-friction surfaces. However, it is important to note that excessive friction or roughness on a surface can potentially impact the tape's ability to stick. If the surface is extremely rough or uneven, it may create air pockets or gaps between the tape and the surface, which can compromise its performance. In such cases, it is recommended to properly prepare the surface by cleaning and smoothing it before applying the tape to ensure optimal adhesion. Furthermore, the durability of the tape can also affect its performance on high-friction surfaces. Some packaging tapes are reinforced with fibers or have a thicker construction, making them more resistant to wear and tear caused by friction. These tapes are often recommended for heavy-duty applications or when packaging items that will experience constant rubbing or sliding on high-friction surfaces. Overall, packaging tape is generally well-suited for use on high-friction surfaces. By considering the tape's adhesive properties, properly preparing the surface, and selecting an appropriate tape, reliable and long-lasting adhesion can be achieved, even in challenging conditions.

- Q: Can packaging tape be used for sealing plastic bags?

- Indeed, sealing plastic bags can be accomplished with the utilization of packaging tape. Designed with robust adhesive properties, packaging tape can effectively secure various items, including plastic bags. To achieve a secure seal and prevent spillage or exposure to air and moisture, the tape can be applied either along the opening or across the entire width of the bag. It is worth mentioning, though, that while packaging tape can serve the purpose, it may not be as efficient as specialized plastic bag sealing techniques like heat sealing or ziplock closures, which are specifically engineered for this particular task.

- Q: Can packaging tape be used for sealing industrial or manufacturing goods?

- Yes, packaging tape can be used for sealing industrial or manufacturing goods. Packaging tape is designed to secure and seal packages, boxes, and cartons, making it suitable for a wide range of applications. It is commonly used in various industries, including manufacturing, to ensure the safe transportation and storage of goods. Packaging tape provides a strong and durable seal, preventing the contents from spilling, getting damaged, or being exposed to external factors such as moisture or dust. Additionally, it offers easy application and removal, making it convenient for sealing large quantities of industrial or manufacturing goods efficiently.

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Yes, packaging tape is designed to be resistant to extreme temperatures and weather conditions. It is typically made with durable materials that can withstand both hot and cold temperatures, as well as protect packages from moisture, rain, and other weather elements.

- Q: I want to be involved in the tape industry, is the parent type their split, but do not know the parent roll cut in segmentation machine is good, or even after the parent roll processing, and also is the problem of the equipment, how much money, thank you

- Buy mother volume back, after four machines processed into finished products can be, the equipment price is: 40 thousand, -4.3 million.

- Q: Does packaging tape come in different adhesion levels for various surfaces?

- Yes, packaging tape does come in different adhesion levels for various surfaces. There are different types of packaging tapes available in the market, each designed to adhere to specific surfaces. For example, there are packaging tapes with low adhesion levels that are ideal for delicate surfaces such as paper or cardboard, as they provide a secure bond without damaging the surface when removed. On the other hand, there are high adhesion packaging tapes that are specifically formulated for sticking to rough or uneven surfaces, such as plastic or metal. These tapes have a stronger adhesive to ensure a secure hold in challenging environments. Additionally, there are also packaging tapes with medium adhesion levels that are versatile and suitable for general-purpose usage on a variety of surfaces. The different adhesion levels allow users to choose the most appropriate packaging tape based on the specific surface they need to adhere to, ensuring optimal performance and reliability.

- Q: Xiangxi investment sealing tape how much profit

- Not wait for shipment, then compensate 4000 yuan per ton, of course, may rise to 15000 yuan a ton, but this risk is great, especially those who have just entered the line

- Q: What are the considerations for using packaging tape on temperature-sensitive items?

- When using packaging tape on temperature-sensitive items, there are several considerations to keep in mind. Firstly, it is important to choose the right type of packaging tape. There are temperature-resistant tapes available specifically designed to withstand extreme temperatures. These tapes are usually made with materials that can withstand high or low temperatures without losing their adhesive properties or deforming. It is crucial to select a tape that is suitable for the temperature range the item will be exposed to during storage, transportation, or any other handling processes. Secondly, it is important to properly store the packaging tape. Extreme temperatures can affect the adhesive properties of tape, causing it to become less effective. It is advisable to store the tape in a climate-controlled environment, away from direct sunlight or areas with excessive heat or cold. This will help maintain the adhesive strength and overall quality of the tape. Additionally, when applying packaging tape to temperature-sensitive items, it is important to ensure that the surface is clean and dry. Any moisture or dust particles on the surface can compromise the adhesion of the tape and lead to inadequate sealing. Properly preparing the surface will help ensure a secure and reliable bond between the tape and the item. Furthermore, it is essential to consider the duration of exposure to extreme temperatures. If the item will be exposed to high or low temperatures for an extended period, it may be necessary to use additional protective measures such as insulation or specialized packaging materials to provide extra insulation. Lastly, it is important to test the tape's performance before using it on temperature-sensitive items. Conducting a small-scale trial or using a sample item can help determine if the tape is suitable for the specific temperature conditions. This will help identify any potential issues or limitations before using the tape on valuable or delicate items. In conclusion, when using packaging tape on temperature-sensitive items, it is crucial to select the appropriate tape, store it properly, prepare the surface adequately, consider the duration of temperature exposure, and test the tape's performance. By considering these factors, one can ensure the safe and secure packaging of temperature-sensitive items.

- Q: Can packaging tape be used for sealing envelopes?

- Yes, packaging tape can be used for sealing envelopes. It provides a strong and secure seal that helps protect the contents of the envelope.

Send your message to us

Custom Polypropylene Packaging Tape - PVC Electrical Insulation Tape New Material Good Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches