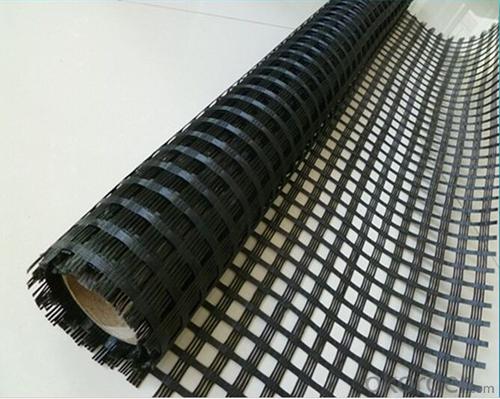

Uniaxial PVC Coated Polyester Geogrid Warp Knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geogrids | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX

|

Model Number: | polyester geogrid | Material: | Polyester | note: | plastic geogrid |

tensile strength: | 15,20,25,30,40,50,60,70,80,90,100,110,120 and so on | mesh size: | 36mm*36mm | roll size: | 3.95*100m or 3.95*50m |

certificate: | CE ISO |

Packaging & Delivery

Packaging Details: | plastic geogrid packing in roll or customized |

Delivery Detail: | 5 days |

Reinforcement Polyester Geogrid :

(Warp Knitted Polyester Geogrid) :

Size | PET30/30--PET400/400; PET40/30--PET600/30 |

Price:FOB QINGDAO PORT | USD 0.3/Sq.m -- 5.0/Sq.m (LARGER QUANTITY WITH NICE PRICE) |

Packing in Roll

|

Roll width 3.95 Meter, 168 rolls in one 40HC Container.

|

Tensile strength at break | 30kn~600kn |

Stretching ratio | 13% |

Grid size | 12.7*12.7mm, 25.4*25.4mm, 50.8*50.8mm |

Mesh size | 9*9mm, 20*20mm, 35*35mm |

Roll width | 1.5m, 2m,3m,3.95m,5.8m |

Roll length | 50m, 100m |

Coating | PVC |

40HC container: | about 20000 Sq.m --50000 Sq.m |

Customize: | You can get more than what you pay for. Min 10000Sq.m |

Place of Origin | SHANDONG DAGENG, TAIAN CITY, SHANDONG, CHINA. |

Certificate | ISO ,CE |

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal ...

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

- Q: Are geogrids fire-resistant?

- No, geogrids are not fire-resistant.

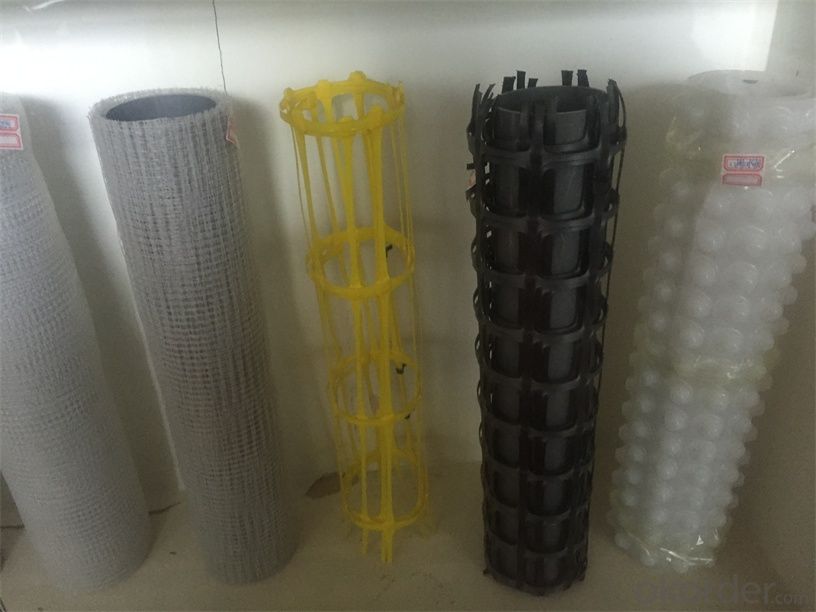

- Q: What are the criteria for the use of plastic geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, project requirements, and installation method. It is essential to consult with geotechnical engineers or geosynthetic specialists who can analyze the specific project needs and recommend the most suitable geogrid aperture shape, which can range from square to rectangular or triangular.

- Q: Geogrid width mean?

- Width is the width of Geogrid

- Q: What are the long-term maintenance requirements for geogrid-reinforced structures?

- The long-term maintenance requirements for geogrid-reinforced structures are generally minimal. Geogrids are designed to provide long-lasting reinforcement and stability to structures, reducing the need for frequent maintenance. However, periodic inspections should be conducted to ensure the integrity of the geogrid and identify any potential damages or signs of degradation. In some cases, routine cleaning and removal of debris may be necessary to prevent clogging or obstruction of the geogrid. Additionally, if any issues or damages are detected, prompt repair or replacement of the geogrid may be required to maintain the structural integrity and performance of the reinforced structure.

- Q: Can geogrids be used in retaining walls for waterfront parks?

- Yes, geogrids can be used in retaining walls for waterfront parks. Geogrids provide reinforcement and stability to the soil, preventing erosion and maintaining the integrity of the retaining wall. They are commonly used in such applications to enhance the strength and durability of retaining walls in waterfront parks.

- Q: How do geogrids help in reducing the risk of landslides?

- Geogrids help in reducing the risk of landslides by reinforcing the soil and increasing its stability. They are typically placed in the ground to provide additional strength and prevent soil movement, effectively distributing the forces acting on the slope. This reinforcement helps to resist the gravitational pull that can cause landslides, reducing the likelihood of slope failure and subsequent damage.

- Q: Are geogrids suitable for slope stabilization?

- Yes, geogrids are suitable for slope stabilization. Geogrids are commonly used in engineering and construction projects to reinforce and stabilize slopes. They provide additional strength and stability to the soil, preventing erosion and potential slope failures. Additionally, geogrids can be easily installed and are cost-effective, making them a popular choice for slope stabilization projects.

- Q: What are the typical applications of geogrids?

- Geogrids are commonly used in various civil engineering applications. They are primarily used for soil stabilization, reinforcement, and erosion control in projects such as retaining walls, slopes, embankments, roadways, and pavements. Geogrids help improve the overall strength and stability of these structures by distributing loads, reducing lateral movement of soil, and preventing soil erosion.

- Q: Can geogrids be used in ground reinforcement for sports fields?

- Yes, geogrids can be used in ground reinforcement for sports fields. Geogrids provide stability, improve load-bearing capacity, and prevent soil erosion, making them a suitable choice for reinforcing the ground in sports fields and ensuring a durable playing surface.

Send your message to us

Uniaxial PVC Coated Polyester Geogrid Warp Knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords