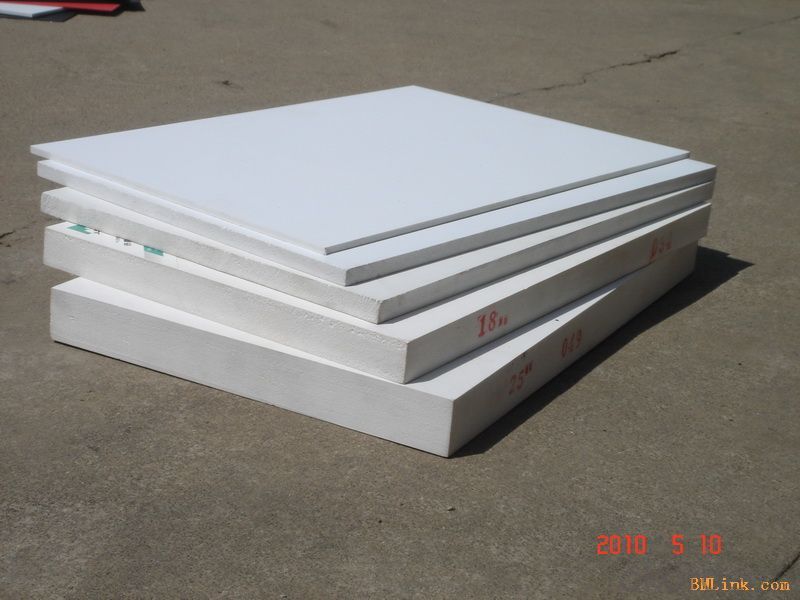

PVC Foam Board, PVC Rigid Foam Board, PVC Celuka Board

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight

Applications

1.exhibition desk, Shelve in supermarket

2.Advertisemen Board and sign board

3.the advertisement sheet for printing,engraving,cutting,sawing

4.Architectural decoration and upholstery

5.decoration for partition wall and shopwindows

6.Waterproof,anticorrosive,metabolic and recyclable,moisture

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation,noise absorption,heat preservation and anti-corrosion.

(3) Tough,rigid with a high impact strength,not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Environmental-friendlygreen and lead-free.

Specification

Usage Life |

more than 50 years |

Hardness | ≥10Mpa |

Elongation at Break | ≥10% |

Water Absorption | ≤1.0% |

Application | Wall cladding, decorating shelf, etc |

Photos

- Q: What are the characteristics of wood?

- A detailed picture of the library too tired again and again seems to understand the understanding of the family to the loss of guilt at home Oh fear ah 15 back to the back Oh is 7 retired 8 good to you you on the database Road, Lulu Lulu have time to come ah Bunny rabbit yu Lulu Lulu refuse to refuse the mold Tu Lulu not cry refused my way to the deficit I have to work hard to mess with the wrong ah ah

- Q: Fu Han plate Malacca and fir lob which is good

- Jinhan, Fu Han are more famous in Hubei local plate brand Malacca, spruce is only representative of the use of raw materials such sheet Like what material can be based on personal preferences, fir to be more expensive

- Q: Health baby mother special plate which brand company production conditions are relatively high?

- New Zealand Zhige plate brand company has a good production conditions, the company has world-class product production conditions and production management level, for the market to provide covers, flooring, metal, lines, latex, the whole room customization of the whole Solutions; we have a wealth of market management experience and channel management capabilities for product distributors and end customers to provide comprehensive professional services.

- Q: Home search needs a thin sheet of paper need to be able to paste the tile as if it is not posted it

- With calcium calcium board or fiber cement board can be, but it is best to fix the board fixed in the brick surface coated with a layer of waterproof plastic, dry and then paste. There is a board with glass glue or stone stickers, but a damp, the effect is not good.

- Q: Help, carpenters plate problem, is the green of Nanjing is good, or the horse's green sea good?

- Luyuan good, Ma On Shan green sea to be careful, mostly fake more. Can really be really good, but the price of 135 is not estimated to be true

- Q: So steel products can be called steel, plates and profiles are steel classification.

- So steel products can be called steel, plates and profiles are steel classification. Plate by thickness in the plate, sheet, plate and plate. Separate the plates by the process. Cold plate, hot plate and so on. Profiles, as the name suggests, angle, groove just belong to the profile.

- Q: Three thousand square plate is good?

- I think you still have to believe that a sub-quality goods, choose the plate, can not just look at the price, but also depends on the quality, reliable quality and stability to deal with home decoration. So I can only say that the home decoration or the need for an environmentally friendly space so I think the election three thousand square or value for money, specifically to see your needs!

- Q: What are the top ten brand names in 2017?

- New Zealand Chi cabinet sheet using the new water-based polymer isocyanate gum, Environmental protection level to the highest national E0 standard, it belongs to the non-formaldehyde series, Completely away from the formaldehyde, benzene and other harmful substances on the human body harm, While preserving the aroma of natural logs

- Q: At present, in addition to solid wood, the most environmentally friendly sheet is E0 level?

- At present, the standard of formaldehyde emission of sheet metal is mainly Chinese standard, which is the so-called national standard, EU standard, and Japanese standard.

Send your message to us

PVC Foam Board, PVC Rigid Foam Board, PVC Celuka Board

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords