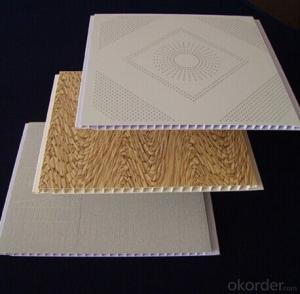

PVC Ceiling Cladding - Hot Stamp Foils with Steady Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

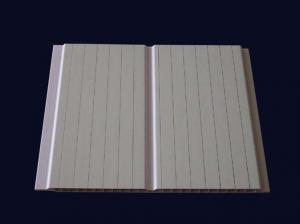

Thickness (mm): 5mm/5.50/6mm

Width (cm): 20cm

Length (m): 0.595-5.95 (according to customer requests)

Weight(kg/SQM): 1.60kgs/1.70kgs/1.80kgs

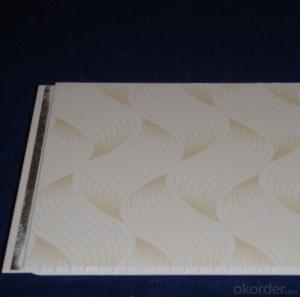

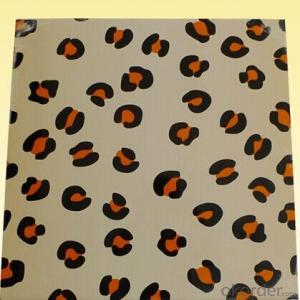

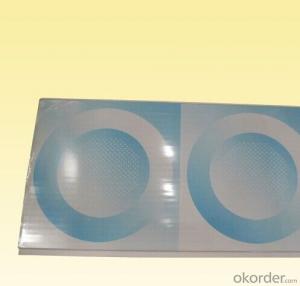

Surface Treatment

Common and High glossy Printing, transfer printing, Laminating with permanent glue, any design as

customer request

Package

PE Film Packing, PVC Film Packing, Hard Paper Box Packing

Product Advantages:

1. Surface treatment: printing, transfer printing and lamination with permanent glue

2. High intensity, high breaking strength, strong colour fastness not easy to deformation, erosion resistant,

mothproof, sound insulation, waterproof, flame retardant, antibiosis, environmental and non-toxic material ,

3. Easily installation, smooth surface, flat, without gap when concatenated

4. more than 500 colors and designs available

5. Competitive price, high quality and good service

6. Useful life more than 30years

7. Pass ISO9001-2008, Nigeria Soncap, NFPA701, B1,B2, M1,M2 and ROHS certificate

Widely Applied indoor and outdoor decoration, House Ceiling, Hotel Ceiling, Restaurant ceiling, Hospital

and school ceiling, indoor and outdoor wall decoration, etc.

Main Product Features:

(1) Where are the ceiling panel can be used?

The panels are designed for covering internal walls or ceilings in any room in the home or commercial rooms.

Especially for the wet environment, such as the kitchen and the bathroom.

(2) How can I install the panels?

Our panels are designed to be installed by the DIY’S. We also provide you with the profiles of installation,

You need very little experience and no special tools.

(3) What temperature range I can use plastic panels in?

Our decorative panels can withstand temperatures up to 140°F (60°C)

Product Specifications:

Images:

- Q: Pvc board how to do the font effect

- With the PVC board or can PVC board has chemical stability, corrosion resistance, hardness, strength, high strength, anti-ultraviolet (anti-aging), fire-retardant (with self-extinguishing), reliable insulation, smooth surface smooth, non-absorbent, , Easy processing and so on

- Q: Who has pvc foam board performance indicators ah?

- Applicable temperature: -50 degrees Celsius -70 degrees Celsius Heating temperature: 70 degrees Celsius -120 degrees Celsius (making profiles) Bending strength: 45.6mpa Low temperature: (-5 degrees Celsius down the impact) 10 times zero broken life: not less than 50 years Product testing methods: (1) board: smooth and smooth, mechanical texture is not obvious, the surface color without color, milky white, no stains on the surface, no obvious pits, no pinholes, no thick holes, cracks. Note: non-milky white foam plate into the recycling waste plate, does not belong to the environmental protection board, environmental protection board does not lead (content is less than Europe and the United States standard). (2) plate side: incision smooth, fine pores, no pinhole, no thick hole, out of powder is not serious, no honeycomb, open fiber from the fall off, do not jump mouth. Note: The above situation to be careful, and then order to do the finished product trouble. (3) thickness measurement: caliper stand surface, the contact seamless seamless, left and right thickness uniform, left and right measurement, the deviation is large, thickness deviation positive and negative 0.2MM as normal. (4) Plate weight algorithm: Weight (g) = L * W * Thickness (cm) * Density, (5) Density algorithm: Density = Weight (g) / L * W * H (cm).

- Q: Pvc board to do the equipment 220V how will live, hand touch PVC board will be the feeling of electricity test pen test really have electricity

- Connect the wire on the board with a wire and then use the screw or nail to connect the other end of the wire to the wall. This will be something to pick up

- Q: Will the production of PVC gray pipe is about 40 meters is normal, after the pipe whitening, from the fish scale, reduce the speed and a little better. What is the reason

- Production process parameters have not changed the formula or mixed the problem

- Q: Ask: a wall of water seepage, back to the tvc board can be sealed up?

- The characteristics of water is always looking for a place out of low-lying cracks ... must cure this course, side may also be carefully checked to see

- Q: What is the best glue on the PVC board glue?

- Pvc special glue, hard and soft different

- Q: I have an old house and recent found a spot on my ceiling where there is a watermark. upon prodding through i see that the spot where the large cast iron drainage pipe that runs to the basement that connects to the 6 PVC bathroom drainage pipe upstairs has developed a small leak. There is a small spot where this white stuff (looks old) has chipped off and that is where the leak is coming from. Nothing major, but still a drip....drip....drip...enough to ruin the drywall, and enough to be fixed. I need to know what kind of material (pvc cement, caulk, etc) i would use to seal up that joint, as ripping it all out isnt an option. Something that preferrably would set when its wet (if possible) as it seems to be nonstop dripping.thanks for the help!

- Try using a repair sleeve made for water lines. It's just a metal clamp with a rubber pad, you tighten it around the pipe with a wrench. You can also try a radiator patch kit. It's putty in a tube, you pinch off a piece, knead it together til it gets warm, and push it in the hole/crack, gets hard as steel in a couple on minutes. Good luck

- Q: just put a plastic ceiling up and my labourer put a dent in the 2nd board there are 9 pvc cladding boards on the ceiling but I cannot start taking them back out from the end to replace it as I have put a walk in shower in and the wet wall shower boards tie them in is there any other way I can replace it I havnt tiled it in yet the boards are silicone and screwed on the lip HELP PLEASEEEEEEEEEE!!! Thanks

- Plastic Ceiling Cladding

- Q: In a thickness of 2.3mm on the board out of the hole 20, the die value of 20.2, the knife has a polished, punch 20, punch out of the hole often crack, and even bubble-like, clearly see the original surface separation Will this question how to solve it, Punching out of the wafer but also pressure back to the product, in order to smooth, I die in the die where the small chamfer, the problem will not appear on this?

- Plate too bad, for high impact plate or discretionary heating environment punching

- Q: Decoration company people said that the aluminum plate to do the effect will be better. But some people say that the length of the aluminum plate is easy to deformation (especially Yuba near the board). What are the quality of the decision? Generally do not buy the thickness of the number of deformation? In addition, my house upstairs from the ceiling of the water pipe is relatively large, the lowest point of the water pipe from the ground also 2.3m. Hanging shed will not appear after the height of the bathroom is too short. Is there a good way to fix it?

- Aluminum buckle plate better point, PVC more love deformation, and aging soon. Not the thickness of the quality of the decision, the best choice of brand name, the general tube installation also warranty 5 - 10 years. As for the height of this can not be changed, the water pipe can not be easily changed, the actual this is not a hardware problem but the design of the problem, it should be said that no one can become widened house, and the design can make people feel the space becomes high width. Mainly pay attention to the use of lines of furniture and so on. Because it can not see so can not specifically said, simply talk about some common, vertical lines can make space feel higher, and the top can extend the light, (that is, although it is 2 points 3 but can be made Z-type in the horizontal That increase the depth of the lamp can also be added to increase the sense of space)

Send your message to us

PVC Ceiling Cladding - Hot Stamp Foils with Steady Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords