Professional Welded Steel Tube/Pipes famous company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Welded Steel Tube ASTM DIN1829:

Welded Steel Tube is formed by drawing a solid billet over a piercing rod to create the hollow shell. We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of welded pipe and professioanl service.

2、Main Features of the Seamless Pipe ASTM DIN1829:

• High manufacturing accuracy

• The higher strength

• The small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Satisfy price

3、Seamless Pipe ASTM DIN1829 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、 FAQ of Welded Steel Tube Steel Pipes:

①Quality

Our products are manufactured strictly according to national and internaional standard, and before delivered out we always take a test

on every pipe . If necessary we could provide our quality certifications and all kinds of testing report,.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②Price

we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Why us?

We can provide both low price and good quality especially we are belong to national company could provide you the best sell-after service .Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

Our Advantages:

1) Fast Delivery: lot of high quality steel pipe in stock lot of factory to produce

2) Quality Assured: Strictly acc. To International standard with System ISO certification

3) Good Service: supplied professional technical guide free of charge at anytime;

4) Reasonable Price: to be better support your business;

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

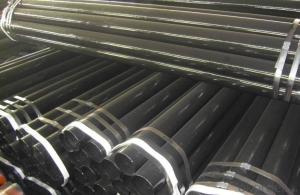

images of products:

Looking forward to doing the corporation with you

Any question, kindly feel free to contact us !

- Q: How are steel pipes protected against electrolytic corrosion?

- Steel pipes are protected against electrolytic corrosion through a variety of methods. One common method is the application of protective coatings on the surface of the pipes. These coatings act as a barrier, preventing direct contact between the steel and the surrounding environment, which includes moisture and other corrosive substances. Coatings such as epoxy, polyethylene, and zinc are commonly used for this purpose. Another method of protection is the use of sacrificial anodes. Sacrificial anodes are made from a metal that is more reactive than steel, such as zinc or aluminum. These anodes are attached to the steel pipes and, as they corrode over time, they sacrifice themselves to protect the steel. This process is known as cathodic protection and is highly effective in preventing electrolytic corrosion. In addition to coatings and sacrificial anodes, proper insulation and electrical isolation are crucial in protecting steel pipes from electrolytic corrosion. Insulating materials, such as rubber or plastic sleeves, are used to prevent direct contact between the pipes and other metals or electrolytes. Electrical isolation can be achieved through the use of dielectric unions or insulating flanges, which prevent the flow of electric current between different sections of the pipeline. Regular maintenance and inspection also play a key role in protecting steel pipes against electrolytic corrosion. Periodic checks for coating integrity, anode condition, and potential electrical leakage are essential to ensure the continued effectiveness of the corrosion protection system. Overall, a combination of protective coatings, sacrificial anodes, insulation, electrical isolation, and regular maintenance is necessary to protect steel pipes against electrolytic corrosion. By implementing these measures, the lifespan of steel pipes can be significantly extended, ensuring the safety and reliability of various applications such as water distribution, oil and gas transportation, and structural support in buildings and infrastructure.

- Q: What is the diameter of the steel tube DN20?

- 1, nominal diameter is nominal diameter, or nominal diameter, or nominal size.2, nominal diameter is a variety of pipe and pipe accessories generic caliber. The same nominal diameter of the tube and pipe accessories can connect with each other, with interchangeability. It is not a real sense of the pipe diameter or diameter, although its value is closer with the pipe diameter or equivalent, is a convenient integer for reference only, are not strict with processing size. Nominal diameter is not the outer diameter, nor the inner diameter, but a nominal size similar to the diameter of the ordinary steel pipe. In order to connect the pipe and pipe fittings in a uniform dimension, each nominal diameter corresponds to an outer diameter, and the inner diameter value varies with the thickness.

- Q: Are steel pipes suitable for use in sewage treatment plants?

- Yes, steel pipes are suitable for use in sewage treatment plants. Steel pipes are durable, corrosion-resistant, and can withstand high-pressure applications, making them an ideal choice for transporting and containing sewage in treatment plants. Additionally, steel pipes can be easily welded, allowing for seamless connections and minimizing the risk of leaks or contamination.

- Q: Are steel pipes suitable for wastewater treatment plants?

- Yes, steel pipes are suitable for wastewater treatment plants. Steel pipes are known for their durability, corrosion resistance, and high strength, making them ideal for handling the demanding conditions of wastewater treatment plants. They can effectively transport and contain wastewater without any structural or functional issues, ensuring efficient and reliable operation of the treatment process.

- Q: What is the purpose of galvanizing steel pipes?

- The purpose of galvanizing steel pipes is to provide corrosion resistance and extend their lifespan.

- Q: What are steel pipes?

- Steel pipes are hollow cylindrical tubes made from steel, which are mainly used for transporting fluids and gases in various industries such as oil and gas, construction, and plumbing. They are known for their strength, durability, and resistance to corrosion, making them an essential component in infrastructure and industrial applications.

- Q: What are the different methods of pipe repair for steel pipes?

- When it comes to repairing steel pipes, there are several methods available that depend on the severity and location of the damage. Below, you will find a list of the most common methods used: 1. Welding: This method is frequently employed for fixing steel pipes, particularly when the damage is confined to a specific area. To execute this repair, the damaged portion of the pipe is removed and replaced with a new piece that is welded securely. Afterwards, the weld is thoroughly inspected to verify its strength and reliability. 2. Pipe wrapping: This approach entails wrapping a layer of fiberglass or epoxy tightly around the damaged section of the pipe. This wrap provides structural reinforcement and effectively prevents further leakage or corrosion. 3. Pipe lining: This technique involves inserting a flexible liner into the damaged pipe. The liner is typically composed of materials such as epoxy, PVC, or cured-in-place pipe (CIPP). Once inserted, the liner is either inflated or heated to conform to the shape of the pipe, creating a new inner surface that is resistant to corrosion and leakage. 4. Slip lining: Similar to pipe lining, slip lining involves placing a smaller diameter pipe inside the damaged one. The smaller pipe acts as a protective sleeve, reinforcing the structure and preventing further deterioration of the original pipe. 5. Pipe bursting: This method is utilized when the damage to the pipe is extensive. A new pipe is pulled through the damaged one using a hydraulic or pneumatic system. As the new pipe is pulled through, it bursts the old pipe, resulting in a larger diameter pipe with minimal disturbance to the surrounding area. 6. Clamp or sleeve repair: In cases where the damage is small and localized, a clamp or sleeve can be applied to temporarily or permanently fix the issue. The clamp or sleeve is placed securely over the damaged section to prevent leakage. It is important to keep in mind that the optimal method for repairing steel pipes depends on factors like the extent of damage, accessibility, cost, and structural requirements. It is recommended to consult with a professional pipe repair specialist or engineer to determine the most suitable method for your specific situation.

- Q: How are steel pipes classified based on pressure ratings?

- Steel pipes are classified based on pressure ratings into various categories such as Schedule 40, Schedule 80, and Schedule 160, with each schedule indicating the maximum pressure the pipe can withstand.

- Q: What are the factors to consider when selecting pipe materials for corrosive environments?

- When selecting pipe materials for corrosive environments, there are several important factors to consider in order to ensure the longevity and effectiveness of the piping system. 1. Corrosion Resistance: The most crucial factor to consider is the corrosion resistance of the pipe material. It is essential to choose a material that is highly resistant to corrosion, as corrosive environments can cause significant damage to pipes over time. Materials such as stainless steel, fiberglass, and certain types of plastics like PVC and CPVC are known for their excellent resistance to corrosion. 2. Chemical Compatibility: It is important to assess the chemical compatibility of the pipe material with the specific corrosive environment it will be exposed to. Different materials have different resistance levels to various chemicals, so it is crucial to ensure that the chosen material can withstand the specific chemicals present in the environment. Consulting chemical compatibility charts and seeking expert advice can help in making the right material selection. 3. Temperature and Pressure Requirements: The temperature and pressure conditions within the corrosive environment should also be considered when selecting pipe materials. Some materials may have limitations in terms of their temperature and pressure resistance, and exceeding these limits can lead to pipe failure. It is important to choose a material that can handle the required temperature and pressure ranges without compromising its structural integrity. 4. Cost: The cost of the pipe material and its installation should also be taken into account. While certain materials may be highly resistant to corrosion, they can also be more expensive. It is essential to strike a balance between the desired level of corrosion resistance and the available budget. 5. Maintenance and Durability: The maintenance requirements and overall durability of the pipe material should be evaluated as well. Some materials may require more frequent inspections, cleaning, or repairs compared to others. Considering the anticipated lifespan of the piping system and the ease of maintenance can help in selecting a material that will provide long-term reliability and cost-effectiveness. In conclusion, when selecting pipe materials for corrosive environments, one should consider factors such as corrosion resistance, chemical compatibility, temperature and pressure requirements, cost, and maintenance and durability. By carefully evaluating these factors, one can choose a pipe material that best suits the specific corrosive environment and ensures a reliable and long-lasting piping system.

- Q: How are steel pipes protected against fire?

- Steel pipes are protected against fire through various methods such as applying intumescent coatings, using fire-resistant insulation, or encasing them in fire-rated enclosures. These measures help to delay the heat transfer and maintain the structural integrity of the pipes during a fire, allowing them to withstand high temperatures and prevent the spread of fire.

Send your message to us

Professional Welded Steel Tube/Pipes famous company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords