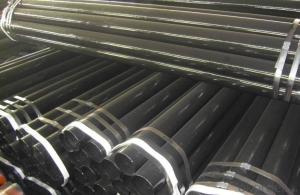

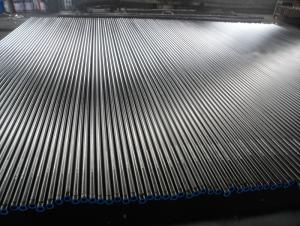

Carton Seamless Steel Pipe ASTM A106/API 5L/ASTM A53 GR.B

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Balck Pipe ASTM A106/API 5L/ASTM A53 GR B:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types.

2、Main Features of Seamless Balck Pipe ASTM A106/API 5L/ASTM A53 GR B:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Balck Pipe ASTM A106/API 5L/ASTM A53 GR B:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe ASTM A106/53 Images:

- Q: What is the role of steel pipes in the construction of bridges and tunnels?

- Steel pipes play a vital role in the construction of bridges and tunnels as they provide structural support and durability. They are commonly used for the fabrication of the framework and foundation of these infrastructures. Steel pipes offer high tensile strength, corrosion resistance, and the ability to withstand heavy loads, making them an ideal choice for ensuring the integrity and longevity of bridges and tunnels. Additionally, steel pipes can be easily welded, allowing for efficient and cost-effective construction methods.

- Q: What is the difference between internal and external coating for steel pipes?

- Internal coating for steel pipes refers to the application of a protective layer on the inner surface of the pipe to prevent corrosion and increase durability. This coating is designed to withstand the flow of fluids or gases through the pipe, ensuring the integrity of the material and minimizing the risk of contamination. On the other hand, external coating for steel pipes involves applying a protective layer on the outer surface of the pipe to safeguard it from environmental factors such as moisture, chemicals, or mechanical damage. This coating acts as a barrier, shielding the pipe from corrosion and extending its lifespan. In summary, internal coating focuses on protecting the inner surface of the steel pipe, while external coating aims to safeguard the outer surface. Both coatings are crucial for ensuring the longevity and reliability of steel pipes in various applications.

- Q: When can I use the PVC pipe and when to use the galvanized pipe?

- PVC pipeline use temperature is -5 to 90 degrees or so, according to the current market price of around 6000 yuan per ton, the price is cheap. Its corrosion resistance is good, can resist most of the acid and alkali, and unlike the steel pipe that is easy to rust, so in the construction of the upper and lower water pipes and other fields have gradually replaced the trend of steel pipe.

- Q: How are steel pipes used in the manufacturing of bicycles?

- Steel pipes are commonly used in the manufacturing of bicycles as they provide strength, durability, and rigidity to the frame structure. The pipes are typically used to construct the main frame, handlebars, seat post, and fork, ensuring a sturdy and reliable bicycle.

- Q: What are the safety precautions for handling steel pipes?

- Some safety precautions for handling steel pipes include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots. It is also important to use proper lifting techniques to prevent strain or injury, as steel pipes can be heavy. Additionally, ensuring a clear and organized workspace, as well as securing the pipes properly during transportation, can help prevent accidents or damage.

- Q: Are steel pipes suitable for high-temperature applications?

- Yes, steel pipes are suitable for high-temperature applications. Steel has excellent heat resistance properties, and steel pipes can withstand high temperatures without deformation or structural failure. Additionally, steel pipes can maintain their strength and durability even under extreme heat conditions, making them a reliable choice for various industrial and commercial applications involving high temperatures.

- Q: How do steel pipes perform in earthquake-prone regions?

- Steel pipes perform well in earthquake-prone regions due to their inherent strength and flexibility. They can withstand the strong seismic forces, thanks to their high tensile strength and ductility. Steel pipes have the ability to absorb and dissipate energy during an earthquake, reducing the chances of structural failure. Additionally, their durability and resistance to corrosion make them suitable for long-term use in such regions.

- Q: What are the different methods of pipe welding for steel pipes?

- There are several different methods of pipe welding for steel pipes, each with its own unique advantages and applications. Here are some of the most common methods: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a manual welding process that uses a consumable electrode coated in flux. The electrode is melted to create the weld, and the flux creates a protective shield around the weld pool. SMAW is versatile and can be used in various positions, making it suitable for both field and workshop applications. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode that is fed through a welding gun. The welding gun also supplies a shielding gas, such as argon or a mixture of argon and carbon dioxide, to protect the weld pool from atmospheric contamination. GMAW is known for its high welding speed and is often used in industrial applications. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuous wire electrode, but the wire is filled with flux instead of relying on an external shielding gas. The flux in the wire produces a protective shield around the weld pool, eliminating the need for a separate gas supply. FCAW is commonly used in outdoor and windy conditions as it provides better protection against atmospheric contamination. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode to create the weld. The weld pool is protected by a shielding gas, typically argon, which is supplied separately. GTAW produces high-quality welds with excellent control, making it suitable for critical applications where precision is crucial. 5. Submerged Arc Welding (SAW): SAW is an automated welding process that uses a continuously fed wire electrode and a granular flux that is poured over the weld joint. The arc is submerged beneath the flux, providing excellent protection against contamination. SAW is commonly used in heavy fabrication and pipeline industries due to its high deposition rates and deep penetration capabilities. These are just a few of the different methods of pipe welding for steel pipes. The choice of method depends on factors such as the application, material thickness, desired weld quality, and available equipment. It is important to select the appropriate welding method to ensure strong, durable, and reliable welds in steel pipe applications.

- Q: What are the different types of expansion joints used with steel pipes?

- There are several types of expansion joints commonly used with steel pipes, including bellows expansion joints, slip expansion joints, and flanged expansion joints. Bellows expansion joints are flexible connectors made of a series of convolutions that allow for axial, lateral, and angular movement. Slip expansion joints consist of two pipe sections with a sliding sleeve in between, allowing for limited axial movement. Flanged expansion joints are designed with flanged ends to provide flexibility and accommodate movement in all directions. These various types of expansion joints are used to absorb thermal expansion, vibration, and misalignment in steel pipe systems.

- Q: Are steel pipes suitable for transporting chemicals?

- Yes, steel pipes are highly suitable for transporting chemicals. This is due to their excellent resistance to corrosion and high durability, ensuring the safe and efficient transportation of various chemicals over long distances.

Send your message to us

Carton Seamless Steel Pipe ASTM A106/API 5L/ASTM A53 GR.B

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords