Prime Hot Dipped Cable Bridge C Channel Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Hot Dipped Cable Bridge C Channel Steel Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS,ASTM /GB/ BS | Dimensions: | 1.0MM--8.0MM | Grade: | Q195-235,SPCC,SPCH,Q195-Q235 |

| Place of Origin: | Hebei China (Mainland) | Brand Name: | CNBM | Model Number: | GTLM-CS-026 |

| Shape: | C Channel | Application: | Steel Structure, Building,1).Steel Structure. 2).Engeneering | Perforated Or Not: | Is Perforated |

| Length: | any length as per ur request. Common not more than 12m | Thickness: | 4.1.0--8.0mm | Surface: | 1). Puch hole or not 2). Painting or not 3). Galvanized,bright |

| Name: | C channel steel/ C section steel | Raw material: | hot rolled strip, cold rolled strip, galvanized steel strip |

Packaging & Delivery

| Packaging Detail: | bundles by steel strip,in container or as ur request |

| Delivery Detail: | 20days after received deposit or affirm contract |

Prime Hot Dipped Cable Bridge C Channel Steel Specifications

Size | Weight (kg/m ) | Size | Weight (kg/m ) |

80×40×20×2.5 | 3.925 | 180×60×20×3 | 8.007 |

80×40×20×3 | 4.71 | 180×70×20×2.5 | 7.065 |

100×50×20×2.5 | 4.71 | 180×70×20×3 | 8.478 |

100×50×20×3 | 5.652 | 200×50×20×2.5 | 6.673 |

120×50×20×2.5 | 5.103 | 200×50×20×3 | 8.007 |

120×50×20×3 | 6.123 | 200×60×20×2.5 | 7.065 |

120×60×20×2.5 | 5.495 | 200×60×20×3 | 8.478 |

120×60×20×3 | 6.594 | 200×70×20×2.5 | 7.458 |

120×70×20×2.5 | 5.888 | 200×70×20×3 | 8.949 |

120×70×20×3 | 7.065 | 220×60×20×2.5 | 7.4567 |

140×50×20×2.5 | 5.495 | 220×60×20×3 | 8.949 |

140×50×20×3 | 6.594 | 220×70×20×2.5 | 7.85 |

160×50×20×2.5 | 5.888 | 220×70×20×3 | 9.42 |

160×50×20×3 | 7.065 | 250×75×20×2.5 | 8.634 |

160×60×20×2.5 | 6.28 | 250×75×20×3 | 10.362 |

160×60×20×3 | 7.536 | 280×80×20×2.5 | 9.42 |

160×70×20×2.5 | 6.673 | 280×80×20×3 | 11.304 |

160×70×20×3 | 8.007 | 300×80×20×2.5 | 9.813 |

180×50×20×2.5 | 6.28 | 300×80×20×3 | 11.775 |

180×50×20×3 | 7.536 | ||

180×60×20×2.5 | 6.673 |

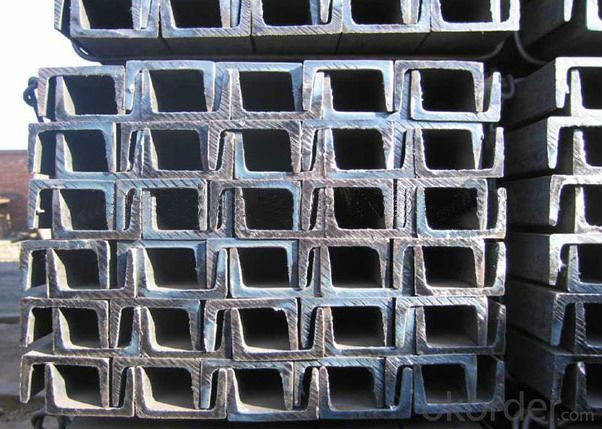

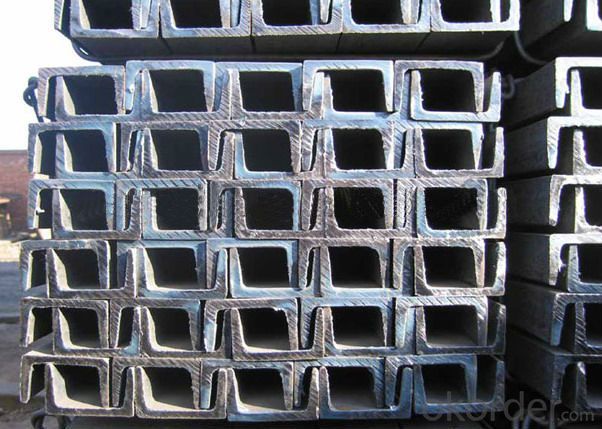

Prime Hot Dipped Cable Bridge C Channel Steel Pictures

- Q: Are steel channels suitable for high-temperature applications?

- High-temperature applications can typically make use of steel channels. Steel possesses the advantageous qualities of strength and resistance to high temperatures, thereby maintaining its structural integrity. However, the appropriateness of steel channels for high-temperature applications relies on several factors, including the grade of steel employed, the temperature range involved, and the duration of exposure to elevated temperatures. Particular grades of steel, such as stainless steel, prove especially well-suited for high-temperature applications due to their exceptional resistance to corrosion and oxidation. Industries like automotive, aerospace, and chemical processing commonly employ stainless steel channels, as these sectors necessitate exposure to heightened temperatures. Determining the suitability of steel channels for high-temperature applications necessitates considering the specific temperature range. Steel commences losing its strength and structural integrity as temperatures rise. Consequently, it becomes crucial to select a steel grade capable of enduring the desired temperature range without compromising its performance. The duration of exposure to high temperatures also warrants consideration. Extended exposure to elevated temperatures can induce structural alterations in steel, including softening or distortion. To prevent significant deterioration, it is essential to employ steel channels designed to withstand the anticipated duration of exposure. In conclusion, steel channels generally prove suitable for high-temperature applications. Nonetheless, ensuring the desired performance and structural integrity necessitates selecting the appropriate steel grade, accounting for the specific temperature range, and evaluating the duration of exposure.

- Q: When building a high building, in order to take scaffolding, the channel into the wall, support scaffolding, etc., after the completion of scaffolding dismantled, channel after taking out, although the hole will be filled well, but the building will not leak it? The building I bought a total of 32 layers, wherein the 9 layer, 17 layer, 25 layer into the channel, I bought 17 layers, the future will Water Leakage ah, good fear, a knowledgeable friend to help answer,...

- Generally not, because, after all, is the facade, not the plane.

- Q: What are the factors that affect the strength of steel channels?

- There are several factors that can affect the strength of steel channels. These factors include the type and quality of the steel used, the dimensions and shape of the channel, the method of fabrication, and the environmental conditions. Firstly, the type and quality of the steel used can greatly impact the strength of the channels. Different grades of steel have varying mechanical properties, such as yield strength and tensile strength, which determine the overall strength of the channels. Higher quality steel with greater strength properties will result in stronger channels. The dimensions and shape of the channel also play a crucial role in its strength. A larger cross-sectional area and a thicker wall can provide greater strength to the channel. Additionally, the shape of the channel, such as whether it is a C-shape or a U-shape, can affect its strength as different shapes distribute loads differently. The method of fabrication is another factor that affects the strength of steel channels. The quality of welding or other joining techniques used can impact the strength and integrity of the channels. Proper fabrication techniques, such as precise welding and proper heat treatment, can enhance the strength of the channels. Furthermore, environmental conditions can have an influence on the strength of steel channels. Factors such as temperature, humidity, and exposure to corrosive substances can affect the structural integrity of the channels over time. For example, exposure to high temperatures can cause the steel to lose its strength and become more susceptible to deformation. In conclusion, the strength of steel channels is influenced by various factors including the type and quality of the steel, the dimensions and shape of the channel, the method of fabrication, and the environmental conditions. Understanding and considering these factors are crucial in ensuring the desired strength and performance of steel channels in different applications.

- Q: What are the different surface treatments available for steel channels?

- There are several surface treatments available for steel channels, each designed to enhance the appearance and performance of the material. Some of the most common surface treatments for steel channels include: 1. Galvanization: This process involves coating the steel channel with a layer of zinc, which provides protection against corrosion. Galvanized steel channels are highly durable and can withstand exposure to harsh weather conditions, making them ideal for outdoor applications. 2. Powder coating: Powder coating involves applying a dry powder to the surface of the steel channel, which is then heated and cured to create a smooth, durable finish. This treatment provides excellent protection against corrosion, impact, and scratches, while also offering a wide range of color options. 3. Painting: Painting is a cost-effective surface treatment option that involves applying a layer of paint to the steel channel. This treatment not only enhances the appearance of the material but also provides protection against corrosion and environmental factors. 4. Anodizing: Anodizing is commonly used for aluminum channels, but it can also be applied to steel channels. This process creates a layer of oxide on the surface of the steel, which improves corrosion resistance and provides an aesthetically appealing finish. 5. Epoxy coating: Epoxy coating involves applying a layer of epoxy resin to the steel channel, which provides exceptional corrosion resistance and chemical resistance. This treatment is often used in industrial settings where the channels are exposed to harsh chemicals or extreme conditions. 6. Hot-dip coating: Hot-dip coating is similar to galvanization but involves immersing the steel channel in a molten zinc bath. This process creates a thick layer of zinc coating, offering enhanced corrosion protection and durability. It is important to consider the specific requirements and application of the steel channel when selecting a surface treatment. Each treatment has its own advantages and limitations, and choosing the right one will ensure the longevity and performance of the steel channel.

- Q: How do steel channels contribute to moisture control in buildings?

- Steel channels contribute to moisture control in buildings in several ways. Firstly, steel channels are often used as part of the building envelope, specifically in the construction of walls and roofs. These channels are designed to provide a barrier against moisture infiltration. When properly installed, they help to prevent rainwater, snow, and other forms of precipitation from seeping into the building, thus protecting the interior from potential water damage and mold growth. Secondly, steel channels can be used in conjunction with waterproofing systems to enhance moisture control. Waterproofing membranes or coatings are applied to the surface of the channels, creating an additional layer of protection against moisture penetration. This is particularly important in areas prone to heavy rainfall or high humidity levels. Furthermore, steel channels can be integrated into the building's drainage system. They are often used to direct rainwater away from the building and into the appropriate drainage channels or downspouts. By efficiently managing rainwater runoff, steel channels help to prevent the accumulation of water around the building, reducing the risk of moisture-related issues such as leaks and foundation damage. Lastly, steel channels can contribute to moisture control by supporting the proper ventilation of the building. Adequate airflow is crucial in regulating moisture levels within a building. Steel channels can be used as part of the ventilation system, allowing for the exchange of air and preventing the buildup of excessive humidity, which can lead to condensation and subsequent moisture issues. In summary, steel channels play a significant role in moisture control in buildings. They provide a protective barrier against moisture infiltration, can be integrated with waterproofing systems, help manage rainwater runoff, and support proper ventilation. By addressing these key aspects, steel channels contribute to maintaining a dry and healthy indoor environment while also prolonging the lifespan of the building.

- Q: Can steel channels be used for playground equipment?

- Yes, steel channels can be used for playground equipment. Steel channels are often used in the construction industry for their strength and durability, making them suitable for use in playground equipment. They provide a sturdy and stable framework that can support the weight of children and withstand the wear and tear of regular use. Additionally, steel channels can be easily shaped and welded to create various structures and designs for playground equipment, such as slides, climbing frames, and swing sets. Their versatility and ability to withstand harsh weather conditions make them an ideal choice for playground equipment that needs to be long-lasting and safe for children to use.

- Q: Calculated weight of channel steel

- A calculating example channel (kg/m) W=0.00785 * [hd+2t (B? C D (+0.349) R2? C R 2 m h=) per channel] weight high b= leg length d= t= average thickness of R= thick waist leg inner arc radius r= end arc radius for 80 mm * 43mm * 5mm. From the metallurgical products directory found the channel of T is 8, R is 8, R is 4, per M weight =0.00785 * [80 * 5+2 * 8 * (43? 5 C) * +0.349 (82? C4 2)]= 8.04kg

- Q: Can steel channels be used in the pharmaceutical industry?

- Indeed, the pharmaceutical industry can utilize steel channels. Renowned for their versatility, steel channels are widely employed across diverse sectors, including pharmaceuticals. Their primary function lies in offering support to mechanical equipment like conveyors and processing machines within pharmaceutical manufacturing facilities. By providing stability, strength, and durability, steel channels prove ideal for applications demanding substantial loads and stringent hygiene standards. Furthermore, steel channels ensure effortless cleaning and sanitization, a pivotal requirement in the pharmaceutical industry to uphold sterility and thwart contamination.

- Q: What are the common methods of joining steel channels together?

- Steel channels can be joined together using various methods, including welding, bolting, riveting, and adhesive bonding. Welding is a widely used technique for joining steel channels. It involves melting the edges of the channels and fusing them together using a welding rod or electrode. This creates a strong and permanent bond. Welding is particularly effective for thick steel channels, offering high strength and durability. Bolting, on the other hand, utilizes bolts, nuts, and washers. Holes are drilled through the channels, and bolts are inserted and tightened with nuts on the opposite side. Bolting is a versatile method that allows for easy disassembly and reassembly of the channels, making it suitable for applications requiring frequent maintenance or adjustments. Riveting, another method, employs metal rivets to connect steel channels. Holes are drilled through the channels, and a rivet is inserted and secured by hammering or pressing. Riveting creates a robust and permanent connection, commonly used in structural applications like bridges and buildings. Adhesive bonding involves the use of industrial-grade adhesives to join steel channels. The adhesive is applied to the surfaces of the channels, and pressure is applied for proper adhesion. While adhesive bonding can provide a strong and durable bond, it is crucial to choose the appropriate adhesive based on the specific steel and application requirements. The selection of the joining method depends on factors such as the application, required strength, ease of assembly and disassembly, as well as the available equipment and resources. Each method has its advantages and limitations.

- Q: Are steel channels suitable for architectural applications?

- Indeed, steel channels are a fitting choice for architectural applications. Their versatility and durability make them an exceptional option for a range of architectural projects. They can serve structural purposes, such as bearing heavy loads or constructing frameworks for buildings. Additionally, steel channels possess the advantage of being highly resistant to corrosion and weathering, rendering them suitable for both indoor and outdoor architectural applications. They can endure harsh environmental conditions, ensuring the longevity of the structures in which they are employed. Furthermore, steel channels provide design flexibility, as they can be easily fabricated and molded to meet specific architectural requirements. They can be cut, welded, and shaped into various forms, allowing architects to fashion distinctive and visually pleasing structures. Steel channels are commonly utilized in architectural applications such as curtain wall systems, facades, roof supports, and staircases. They provide strength and stability while also introducing a modern and industrial aesthetic to the design. To summarize, steel channels are highly appropriate for architectural applications owing to their strength, durability, resistance to corrosion, and design flexibility. They offer architects and designers the opportunity to create innovative and enduring structures.

Send your message to us

Prime Hot Dipped Cable Bridge C Channel Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords