PRESSED WIRE ROPE SLINGS (FIBER CORE)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

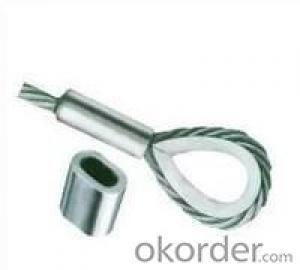

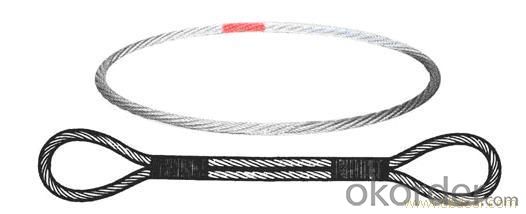

Overview of the pressed wire rope sling

Pressed Steel Wire Rope Sling is made by using the best high quality steel wire rope and produced with the most professional equipments and technics.It is processed by the steel wire rope pressing sleeve machine. The sling is widely used in the field of machinery, metallurgy, construction, shipping, bridge project, gymnasium, oil field, fishing, drilling, colliery and ports etc.

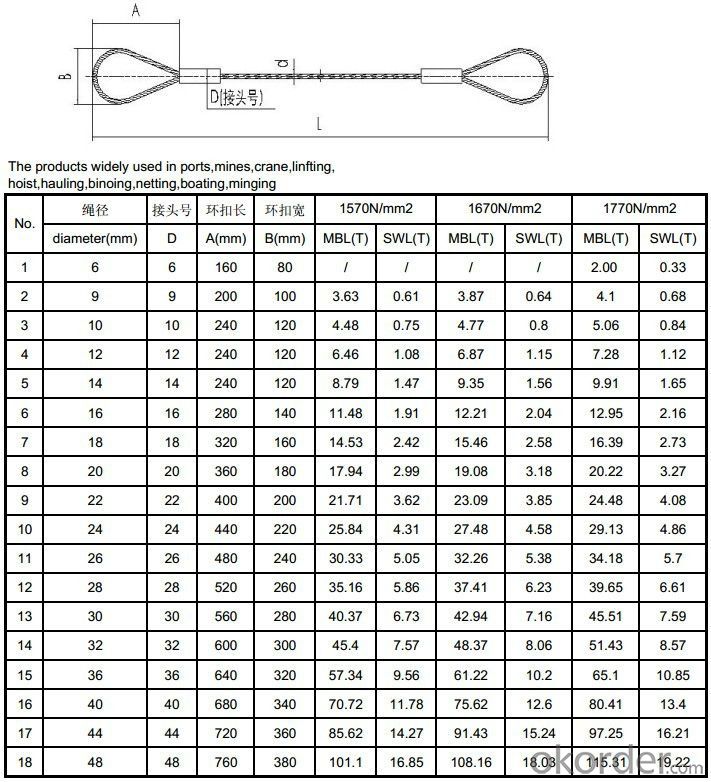

Technical Data

Advantages

1.high strength,

2.light self weight,

3.being steady at work,

4.being not easily broken suddenly and so on

Processing modes

Press the end or both ends to be rings.

It can be combined as sing leg sing ,two-leg sling, tree-leg sling, four-leg sling or more.

How to use

You can choose the wire rope sling made of galvanized steel wire rope to enhance the anti-rust capability.

Besides the abrasion of the outer layer,, it will be broken gradually as the metal fatigue caused by repeated bending when it bypasses the hook and the lifted goods, so the ratio between the hook or the lifted good and the diameter of the steel wire rope decides the service life of the steel wire rope sling.

The pressed wire rope sling is mainly used in transportation which need high strength sling.

Forbidden to stay below the lifted goods or across the goods when working.

FAQ

Q: How’s your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

Picture

- Q: How are steel products used in the railway industry?

- Steel products are extensively used in the railway industry for various applications. Steel is commonly used for manufacturing railway tracks, train wheels, and various structural components of the railway infrastructure. Additionally, steel is used in the construction of railway cars, locomotives, and various equipment such as bridges, tunnels, and signaling systems. Its high strength, durability, and ability to withstand heavy loads make steel an ideal material for ensuring the safety and efficiency of the railway system.

- Q: What are the different types of steel chains and their applications?

- There are several types of steel chains, each designed for specific applications. Some common types include: 1. Proof coil chains: These are general-purpose chains used for towing, securing loads, and restraining objects in various industries. 2. Grade 30 chains: Also known as Grade 30 proof coil chains, these are commonly used in light-duty applications, such as agriculture, construction, and general-purpose lifting. 3. Grade 43 chains: These chains have higher tensile strength than Grade 30 chains and are suitable for heavier-duty applications, including transportation, logging, and towing. 4. Grade 70 chains: Known as transport chains, these chains are specifically designed for securing cargo on trucks, trailers, and flatbeds. They have a higher strength-to-weight ratio, making them ideal for load binding. 5. Grade 80 chains: These chains are mostly used in lifting applications due to their high strength and durability. They are commonly found in construction, mining, and oil and gas industries. 6. Grade 100 chains: These chains have the highest tensile strength and are primarily used for heavy-duty lifting and rigging applications. They are commonly seen in shipyards, steel mills, and offshore operations. 7. Stainless steel chains: These chains are resistant to corrosion and are suitable for applications where exposure to moisture or chemicals is a concern. They are commonly used in food processing, marine environments, and medical equipment. Overall, the choice of steel chain depends on the specific application requirements, load capacity, environment, and desired level of durability.

- Q: What are the different types of steel springs and their uses?

- There are several types of steel springs, each designed for specific applications. Some common types include compression springs, which are used to resist compressive forces and store energy; extension springs, which resist stretching and are commonly found in trampolines or garage doors; torsion springs, which generate rotational force and are used in clothespins or mousetraps; and flat springs, which provide flexibility in limited spaces, such as in automotive suspensions. Each type of spring has a unique design and purpose, allowing them to be utilized in a wide range of industries and products.

- Q: What are the main properties of steel?

- The main properties of steel include high strength, durability, and excellent tensile and compressive strength. Steel also has a high melting point, good thermal conductivity, and is resistant to corrosion and rusting. It is a versatile material that can be easily formed and shaped, making it suitable for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q: What are the common types of steel products used in the pet care and veterinary industry?

- Some common types of steel products used in the pet care and veterinary industry include stainless steel cages, surgical instruments, examination tables, and equipment such as scales and kennels.

- Q: What are the advantages of using steel products over other materials?

- There are several advantages of using steel products over other materials. Firstly, steel is known for its exceptional strength and durability, making it highly resistant to wear, tear, and extreme weather conditions. Secondly, steel products have a longer lifespan compared to other materials, reducing the need for frequent replacements. Additionally, steel is a versatile material that can be easily molded and shaped to meet specific design requirements. Moreover, steel is recyclable, making it an environmentally friendly choice. Lastly, steel offers excellent fire resistance, making it a safer option in various applications.

- Q: What are the different types of steel forgings and their applications?

- There are several types of steel forgings, including open-die forgings, closed-die forgings, and seamless rolled ring forgings. Open-die forgings are used for large and complex components, such as turbine shafts and pressure vessels. Closed-die forgings are ideal for producing smaller, intricate parts like gears and bolts. Seamless rolled ring forgings are commonly used in the manufacturing of bearings, gears, and flanges. Each type of forging offers unique properties and applications, making them suitable for various industries such as aerospace, automotive, and construction.

- Q: What are the different types of steel sheet and their uses?

- There are several types of steel sheets available, each with distinct properties and uses. Some common types include hot-rolled steel, cold-rolled steel, galvanized steel, and stainless steel. Hot-rolled steel sheets are often used in construction and manufacturing due to their strength and durability. Cold-rolled steel sheets, on the other hand, are smoother and have tighter tolerances, making them suitable for applications requiring precise dimensions. Galvanized steel sheets have a protective zinc coating, making them resistant to corrosion, and are commonly used in outdoor structures or for automotive parts. Stainless steel sheets are known for their resistance to corrosion and high temperature, making them ideal for applications in food processing, medical equipment, and chemical industries. Overall, the choice of steel sheet type depends on the specific requirements and intended use of the product.

- Q: What are the different types of steel beams and their applications?

- There are several types of steel beams used in construction and their applications vary based on their shape and properties. Some common types include I-beams, H-beams, and C-beams. I-beams are commonly used in structural applications, such as for supporting heavy loads and spanning long distances. H-beams are often used in residential and commercial construction for their strength and versatility. C-beams, also known as channel beams, are commonly used in applications where lightweight structural support is needed, such as in the construction of bridges or mezzanines. Overall, the choice of steel beam depends on the specific requirements of the project and the load-bearing capacity needed.

- Q: What are the different types of steel products used in the manufacturing of educational toys?

- Some examples of steel products used in the manufacturing of educational toys include steel balls for building sets, steel springs for kinetic toys, and steel wires for connecting components in engineering kits.

Send your message to us

PRESSED WIRE ROPE SLINGS (FIBER CORE)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords