Prepainted Hot Dip Galvanized Steel Coil(PPGI COIL)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

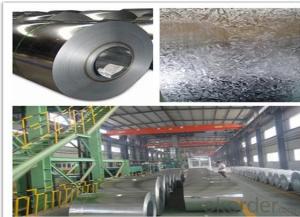

Galvanized steel coil

1.Size:0.1-7.0x600-1500xC

2.ID:508mm/610mm

3.Standard:JIS G3302 ASTM A653

4.Zinc coating:40-275G

galvanized steel coil

| product name | Galvanized steel coil |

| thickness | 0.1mm-7.0mm |

| width | 600mm-1500mm 762mm,914mm,1000mm,1200mm,1219mm,1250mm |

| zinc coating | 40g-275g 40g, 60g, 80g, 100g, 120g, 140g,180g, 200g, 250g, 275g |

| standard | ASTM, AISI, DIN, GB |

| material | SGCC,DC51D,DX51D,DX52D,,SGCD,Q195,Q235,SGHC,DX54D, S350 GD, S450 GD,S550 GD |

| spangle | zero spangle, regular spangle or normal spangle |

| surface treatment | chromated and oiled, chromated and non-oiled |

| packing | export standard. |

| payment | T/T or L/C |

| min order | 1 tons |

coil weight | 6-8ton or as client requirement |

quality | soft or hard quality |

Galvanized Steel Coil

| STEEL GRADE | CHEMICAL COMPOSITION % | MECHANIC PROPERTY | C.B OF COATING | COATING | ||||||

| C | Si | Mn | S | P | T.S | Y.S | E.L | |||

| x103 | x103 | x102 | x103 | x103 | Mpa | Mpa | % | d=0 180° | G/M² | |

| JIS G3302 SGCC | 12 | 30 | 41 | 31 | 21 | 480 | 300 | 13 | OK | Z60-150 |

| JIS G3302 SGCH | 12 | 10 | 21 | 18 | 8 | 680 | 650 | OK | Z60-150 | |

| ASTM A653 CS.B | 20 | 30 | 60 | 35 | 30 | 386 | 205~380 | 20 | OK | Z80-275 |

| DX51D+Z | 29 | 21 | 18 | 1.8 | 11 | 355 | 245 | 38 | OK | Z80-275 |

| G550 | 20 | 6 | 73 | 5 | 17 | 715 | 654 | 8 | OK | Z80-275 |

(1) Coil ID: 508/610mm, Coil weight: 3-8Ton

(2) Top coating 15-25um, back coating 5-15um, RAL international color

(3) With/Without PE film, Smooth/Matt finish

FAQ of Hot Dip Galvanized Steel Coil:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test on every coil before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

Hot Dip Galvanized Steel Coil Images:

- Q: What are the common quality control measures for steel coils?

- There are several common quality control measures that are implemented for steel coils to ensure their performance and reliability. These measures are crucial in maintaining the overall quality of the steel coils and ensuring that they meet the required standards and specifications. Firstly, dimensional checks are conducted to ensure that the steel coils have the correct thickness, width, and length. This is important as any deviations from the specified dimensions can greatly affect the performance and usability of the coils. Next, visual inspections are carried out to identify any surface defects or imperfections such as scratches, dents, or corrosion. These inspections help in identifying any potential issues that may compromise the structural integrity of the coils or affect their aesthetic appearance. Furthermore, mechanical property tests are conducted to determine the strength, hardness, and other mechanical characteristics of the steel coils. These tests help in assessing the performance and durability of the coils under different conditions and loads. Chemical composition analysis is also an important quality control measure for steel coils. This involves analyzing the composition of the steel, including the presence of any impurities or elements that may affect its properties. It ensures that the steel coils are made from the correct grade and meet the required chemical specifications. Coating inspections are another vital quality control measure. If the steel coils are coated with protective layers, it is essential to check the adhesion, thickness, and uniformity of the coatings. This helps in ensuring that the coils have adequate protection against corrosion and other environmental factors. Lastly, various non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, or eddy current testing are employed to identify any internal defects or abnormalities in the steel coils. These tests help in detecting issues such as cracks, inclusions, or discontinuities that are not visible through visual inspection. Overall, the common quality control measures for steel coils include dimensional checks, visual inspections, mechanical property tests, chemical composition analysis, coating inspections, and non-destructive testing. These measures are essential in maintaining the quality and reliability of steel coils and ensuring that they meet the required standards and customer expectations.

- Q: i wanna buy a sharp carbon steel sword the swords i want are a 200 layer carbon steel katana or a hand forged high carbon steel katanna or a hand sharpened sword which one would be sharper/stronger

- actual katanas choose universal upkeep, they rust actual and uninteresting rapidly. in case you get a replica possibility is that's going to ruin the 1st time you hit something with it. in case you will discover one, the WW2 officers swords have been of stable high quality and the in demand metals recommend it would not rust or uninteresting as actual. in case you do insist on getting a carbon scouse borrow blade be waiting to grease it frequently. that's going to rust on the point out of moisture.

- Q: many sword sellers sell swords made of 440 and stainless, i know those are both totally **** for real swords. so are 1045, 1060, or 1095 good grades of steel for a sword?

- Carbon Steel is the most common, while most live-steel(designed for use) ready sword utilize on of the spring steels you mentioned. Hybrid steel like those used in the Slayer series seem neigh-indestructible. The steel should be strong enough to not notch on a strike, but flexible enough to flex when you bend it, lest it shatter on a hard blow.

- Q: I'm missing the arguement, and I've seen another question like this... but the steel toe issue has 2 scenario's right?... Let me label them out, the 2nd is the one that no one talks about?Note to anyone - how are your catapillar boots, your wolverines, and then your cheap walmart/sears brands?1. Steel toe on, toes get cut off because of something falling on them. OUCH!.. Reattach perhaps?2. This one is what I question. No steel toe, large object falls on toes. SMASH... Pudding in your shoes.Wouldn't it be safer to say you'de be better off with a steel toe?

- I have been wearing Brahma brand steel toe work boots for the past 10 years (no, not the same pair for 1o years.. Each pair last me 2-4 years). They have ANSI class 75 steel toes. I work with cars, engines, tools all day long.. In the last 10 years I have had a transmission fall on my foot from about 2 feet high.. A bare cast iron engine block (153 lbs) break the bolts holding it to an engine stand and land on both of my feet. A camaro back over my foot with it's left rear wheel. Non of those things even dented the steel toe.. Just cut the leather covering the steel. No harm at all was done to my toes/feet. With out the steel toe boots, I know my toes/feet would have been broken.. 10 years so far, and from my results I plan on wearing steel toe boots for atleast another 30 years.

- Q: How do steel coils contribute to the circular economy?

- Steel coils contribute to the circular economy by enabling the recycling and reuse of steel. When products reach the end of their life cycle, steel coils can be easily melted down and repurposed to create new products. This reduces the need for extracting virgin materials, saves energy, and minimizes waste. Additionally, the durability and long lifespan of steel coils ensure that they can be used in multiple cycles, further promoting a sustainable and circular approach to manufacturing and consumption.

- Q: Can steel coils be coated with tin?

- Yes, steel coils can be coated with tin.

- Q: How are steel coils used in the construction industry?

- Steel coils are commonly used in the construction industry for various purposes such as fabricating structural components, manufacturing steel pipes, and producing metal roofing and siding materials. The coils are unrolled and processed into different shapes and sizes to meet the specific requirements of construction projects.

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- Tips For Cleaning Your Stainless Steel No matter if you are in an industrial kitchen or just your household kitchen, maintaining the look and the cleanliness of your stainless is essential. There are plenty of products on the market that claim to be able to help you, but you can also do just as good with just knowing how to handle it. Stainless steel is difficult to clean because streaks and fingerprints show up easily. It is easier to see grime, grease and fingertips on stainless than on windows. To help you to keep your stainless steal countertops, utensils and appliances clean, follow these basic rules of thumb. Much more at web page!!

- Q: What are the different types of steel coil finishes for aesthetics?

- There are several different types of steel coil finishes that are commonly used for aesthetic purposes. These include brushed finishes, polished finishes, embossed finishes, and patterned finishes. Each of these finishes can give the steel coil a unique look and texture, allowing it to be used in various design applications.

- Q: What are the common maintenance practices for steel coils?

- Common maintenance practices for steel coils include regular cleaning to remove dirt, dust, and other contaminants, inspection for any signs of corrosion or damage, proper storage to prevent moisture and rusting, and regular lubrication of moving parts to ensure smooth operation. Additionally, it is important to handle and transport the coils with care to avoid any bending or distortion.

Send your message to us

Prepainted Hot Dip Galvanized Steel Coil(PPGI COIL)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords