Prepainted Galvanized Rolled Steel Coil-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

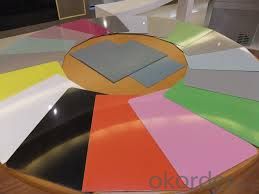

Prepainted Galvanized Steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

PrepaintedGalvanized Steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .For color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.Which is an ideal material;for manufacturing board.

Specification:

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications:

Out door: roof, roof structure, surface sheet of balcony, frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door: door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Images:

Packaging & Delivery :

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

- Q: How are steel coils used in the production of metal partitions?

- Steel coils are an essential component in the production of metal partitions. These coils are typically made from high-quality steel and serve as the raw material for manufacturing the partitions. Firstly, the steel coils undergo a process called slitting, where they are cut into narrower strips of the desired width. This enables manufacturers to customize the size of the metal partitions according to specific project requirements. After slitting, the steel strips are then fed into a roll forming machine. This machine gradually shapes the strips into the desired profile for the metal partitions. The roll forming process involves passing the steel strips through a series of rollers, which progressively bend and form the metal into the desired shape and dimensions. Once the metal has been formed into the desired shape, it is cut into appropriate lengths to create individual partitions. These partitions are then further processed, such as through welding or spot welding, to join different components together and enhance their structural integrity. Steel coils are preferred for metal partition production due to their strength, durability, and versatility. The use of steel ensures that the partitions can withstand heavy loads, resist corrosion, and provide long-lasting performance. Additionally, steel coils offer a high degree of design flexibility, allowing for the creation of various partition styles, such as solid panels, perforated screens, or mesh partitions. Overall, steel coils play a crucial role in the production of metal partitions by providing the necessary raw material, strength, and customization options required for these versatile architectural elements.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, there are several factors that need to be considered. These factors include the type of application, the required strength and durability, the desired aesthetic appearance, the budget, and any specific industry standards or regulations that need to be met. Firstly, it is important to determine the type of application for which the steel coils will be used. Different applications may require different types of steel with varying properties. For example, if the coils will be used in structural construction, high-strength steel with excellent structural integrity may be required. On the other hand, if the coils will be used in automotive manufacturing, steel with good formability and weldability may be more suitable. The required strength and durability is another crucial factor to consider. This includes factors such as the load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures or environmental conditions. The steel coils must be able to withstand the specific stresses and strains that will be placed upon them in the intended application. The desired aesthetic appearance is also important, especially in applications where the steel coils will be visible. Factors such as the surface finish, color, and texture of the steel coils may need to be considered. This is particularly relevant in industries such as architecture or interior design, where the visual appeal of the steel is a key consideration. Budgetary constraints should also be taken into account when selecting steel coils. Different grades and types of steel can vary significantly in price. It is important to find a balance between the desired properties and the available budget. Sometimes, it may be necessary to compromise on certain factors in order to meet budgetary constraints. Lastly, any specific industry standards or regulations should be considered when selecting steel coils. Certain industries, such as aerospace or automotive, may have strict requirements for the materials used in their products. In such cases, it is crucial to ensure that the selected steel coils meet all necessary standards and regulations. In conclusion, when selecting steel coils for a specific application, factors such as the type of application, required strength and durability, desired aesthetic appearance, budget, and industry standards or regulations should all be carefully considered. By taking these factors into account, one can make an informed decision and choose the most suitable steel coils for their specific application.

- Q: I live in Dubai. I want to make a damascus steel sword and have no idea where to get the steel or what sort of steel I should get.First to adress the access of my steel...I need to get some low carbon and high carbon steel for the Damascus....what sort of steel is recommended for this? Also where would I be able to get my hands on it (Internet options e.g websites or locations)THANKS

- hI Jordan damascus steel is not actually a steel it is a composite material like the damascus rifle barrels the Afghan's use it is made from wire wrapped around an inner mandrel the beaten on an anvil till all the wire becomes one so it is several types of iron and steel beaten together and forged to produce it so it is not something you can actually buy as a material the tribesmen that produce these swords have these secret methods of doing this so there is the first problem. it is not like cast steel which is what most swords are made of it is far more complex in it's construction. so you may need to do a lot of research to find out how. what is a similar idea is the SAMURAI sword that is made up of combining different steels together and forged into a very sharp and capable killing blade.

- Q: is stainless steel a good steel for sensitive skin? or does it have to be surgical or sterling silver?

- When I worked at Spencer's the jewelry would usually said what grade/type of metal it was. As long as it says 316L surgical steel you should be ok. But like another person said, go to a professional piercer and buy jewelry there because you know that you're getting good quality. You get what you pay for!

- Q: How to solve steel plate storage

- According to the principle of "first in first out" to carry out the turnover, organize the logistics, reduce the large amount of moving plate, reasonable arrangement, easy to steel coil into the use of state.

- Q: How are steel coils used in the production of scaffolding?

- Scaffolding production heavily relies on steel coils as they serve as the primary raw material for manufacturing various components of scaffolding systems. These coils, typically composed of high-quality steel, are processed through cutting, shaping, and welding operations to obtain the desired dimensions and shapes for scaffolding components, including vertical and horizontal tubes, diagonal braces, and base plates. The main structural elements of scaffolding are the tubes and pipes formed from steel coils. These elements are responsible for constructing the framework of the scaffolding, comprising vertical uprights or standards, horizontal ledgers, and transoms that connect them. By providing strength, stability, and load-bearing capacity, these components ensure the safety of workers operating at elevated heights. Furthermore, diagonal braces, an essential part of scaffolding, are manufactured from steel coils. These braces are strategically installed diagonally between the vertical standards to reinforce the scaffolding structure, adding extra support and stability to prevent swaying or collapsing. Another crucial component produced from steel coils is the base plate. These plates serve as the foundation for the scaffolding structure, offering a solid and stable base to evenly distribute weight and load. Typically positioned at the bottom of each vertical standard, they play a vital role in maintaining stability and preventing sinking or sliding. To summarize, steel coils play a fundamental role in scaffolding production. Through their transformation into tubes, pipes, braces, and base plates, they form the framework and provide the necessary strength, stability, and load-bearing capacity for safe and efficient scaffolding systems.

- Q: What's the length of a coil of cold rolled steel? Is there a standard?

- In 2.0*1000*C calculations, it is assumed that the formula for the length of 5T in this volume is 5000/ (2.0*1000*1000*7.93) = the total number of meters. First, the weight of one meter is calculated by dividing the total weight by the single weight, that is, the theoretical length of the volume

- Q: is red steel any good??????? not sure im really impressed but im not really into fighting games but it looks cool.... so whats your views guys???????anyone bored of smooth moves yet?anyone think the new sonic is bit cra ppy !!!!!!!!!!! darn them any new goooood games coming oput on the wii??

- Have you tried Zelda or Trauma Center? Those should give you a good ride for your money. If you have a few bucks lying around pick either of them up.

- Q: How do steel coils contribute to the sustainability of construction projects?

- Steel coils contribute to the sustainability of construction projects in several ways. Firstly, steel is a highly durable and long-lasting material. Steel coils are manufactured to withstand extreme weather conditions, corrosion, and other external factors, making them ideal for construction projects that require strength and longevity. This durability reduces the need for frequent repairs and replacements, thus minimizing waste and resource consumption over time. Additionally, steel coils are recyclable. At the end of their lifespan in a construction project, steel coils can be easily and efficiently recycled. This process requires less energy compared to the production of new steel, resulting in reduced carbon emissions and environmental impact. Moreover, the recycled steel can be used in various industries, including construction, further promoting sustainability and resource conservation. Furthermore, steel coils contribute to the sustainability of construction projects by offering design flexibility. Steel is a versatile material that can be easily shaped, cut, and molded into different forms and sizes. This allows for efficient construction practices, reducing material wastage and optimizing resource utilization. Additionally, the lightweight nature of steel coils allows for ease of transportation and installation, further reducing fuel consumption and associated greenhouse gas emissions. Lastly, steel coils contribute to the sustainability of construction projects through their energy efficiency. Steel is an excellent conductor of heat and electricity, making it ideal for energy-efficient buildings. Steel coils can be used in the construction of walls, roofs, and other components that help to insulate buildings and reduce energy consumption for heating and cooling. This results in lower energy bills for the occupants and reduces the overall carbon footprint of the construction project. In conclusion, steel coils contribute to the sustainability of construction projects through their durability, recyclability, design flexibility, and energy efficiency. By using steel coils, construction projects can reduce waste, conserve resources, minimize environmental impact, and optimize energy consumption, thus promoting a more sustainable and environmentally friendly approach to construction.

- Q: How are steel coils inspected for camber?

- To ensure the quality and suitability of steel coils for further processing, various methods are employed to inspect their camber. One commonly used approach is visual inspection, where trained inspectors carefully examine the coils for any visible indications of camber. They search for any deviations from a perfectly straight surface, such as bows or curves, which serve as signs of camber. Another method involves the use of specialized equipment, including straightedges, measuring tapes, and laser devices. Inspectors place the straightedge along the length of the coil to assess any gaps or spaces between the coil and the straightedge. If a significant deviation is detected, it signifies the presence of camber. Measuring tapes are also utilized to measure the distance between the coil and the straightedge at multiple points along its length. This enables inspectors to ascertain the extent of camber and determine if it falls within acceptable tolerance limits. In some cases, laser devices are employed to provide a more precise measurement of camber. These devices emit a laser beam that reflects off the surface of the coil and is subsequently analyzed to determine the presence and magnitude of camber. Furthermore, advanced technologies such as computer vision systems and artificial intelligence algorithms are now being integrated into the inspection process. These technologies have the capability to analyze images or videos of the steel coils and automatically detect any camber, thereby delivering accurate and efficient inspection results. In conclusion, the inspection of steel coils for camber involves a comprehensive approach that combines visual inspection, manual measurements using straightedges and measuring tapes, and the utilization of advanced technologies. This multifaceted approach ensures effective detection and control of camber, thereby upholding the quality and integrity of the steel coils.

Send your message to us

Prepainted Galvanized Rolled Steel Coil-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords