Prepainted aluminum Zinc rolled Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

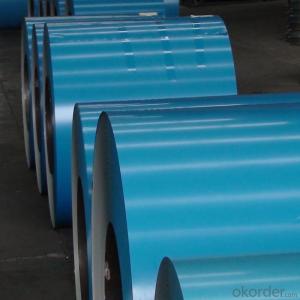

Structure of Aluminum Zinc Rolled Coil

Description of Aluminum Zinc Rolled Coil

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Aluminum Zinc Rolled Coil for Construction Roof

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Aluminum Zinc Rolled Coil for Construction Roof

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction

Product | Hot Dipped Galvanized Steel Coil / Galvalume /Aluzinc Steel coil |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 3-6 tons |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, there are several factors that need to be considered. These factors include the type of application, the required strength and durability, the desired aesthetic appearance, the budget, and any specific industry standards or regulations that need to be met. Firstly, it is important to determine the type of application for which the steel coils will be used. Different applications may require different types of steel with varying properties. For example, if the coils will be used in structural construction, high-strength steel with excellent structural integrity may be required. On the other hand, if the coils will be used in automotive manufacturing, steel with good formability and weldability may be more suitable. The required strength and durability is another crucial factor to consider. This includes factors such as the load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures or environmental conditions. The steel coils must be able to withstand the specific stresses and strains that will be placed upon them in the intended application. The desired aesthetic appearance is also important, especially in applications where the steel coils will be visible. Factors such as the surface finish, color, and texture of the steel coils may need to be considered. This is particularly relevant in industries such as architecture or interior design, where the visual appeal of the steel is a key consideration. Budgetary constraints should also be taken into account when selecting steel coils. Different grades and types of steel can vary significantly in price. It is important to find a balance between the desired properties and the available budget. Sometimes, it may be necessary to compromise on certain factors in order to meet budgetary constraints. Lastly, any specific industry standards or regulations should be considered when selecting steel coils. Certain industries, such as aerospace or automotive, may have strict requirements for the materials used in their products. In such cases, it is crucial to ensure that the selected steel coils meet all necessary standards and regulations. In conclusion, when selecting steel coils for a specific application, factors such as the type of application, required strength and durability, desired aesthetic appearance, budget, and industry standards or regulations should all be carefully considered. By taking these factors into account, one can make an informed decision and choose the most suitable steel coils for their specific application.

- Q: I saw an amazing flamenco player, however i have a steel string guitar, where he had a nylon stringed one. So i was wndering if its possible to play flamenco songs on the steel string guitar, and where could i find a tab for it? are there tabs for rasegueados?

- I routinely play Flamenco on a steel-string acoustic as I dislike playing my two classicals because of the neck size and tuning problems. I prefer keeping my calluses toughened sufficiently and I do that on my HD-35 Martin and sometimes on my J45/50 Gibson. So enjoy all genres of music on your steel stringed guitar.

- Q: Steel is no doubt a better constructin material but it is only in practice in developed country.i would like that we should high lights the benifits and negatives of steel to make the steel more clear as a construction material.Hope some expert to address this topicMD

- Steel Structure considered as the most efficient and fast in completion of any project, specially the high rise buildings, also the logistics during construction is less complicated than the normal methods, Steel Structure has so many advantages vs the disadvantages, and highly recommended for commercial buildings

- Q: How are steel coils processed and shaped for specific applications?

- Steel coils are processed and shaped for specific applications through a systematic manufacturing process. Initially, the coils are uncoiled and flattened, followed by cleaning and coating to protect against corrosion. Then, they undergo a series of shaping processes such as rolling, bending, or cutting, depending on the desired application. These processes help transform the steel coils into various forms, including sheets, plates, or strips, which can be further fabricated into specific products like automobiles, appliances, or construction materials.

- Q: How do steel coil manufacturers handle custom orders?

- Custom orders for steel coils are handled by manufacturers through a methodical process. They begin by comprehending the specific requirements of the customer and engaging in detailed communication to gather information. This includes dimensions, tolerances, and other special needs. Manufacturers may offer technical expertise to ensure the feasibility of the custom order. Once the requirements are clarified, manufacturers proceed with designing and engineering the custom steel coils. Advanced software and engineering tools are utilized to create detailed designs and specifications that cater to the customer's unique needs. Prototypes or samples may be created for the customer's approval before full-scale production. After the design phase, manufacturers initiate the production process by sourcing the appropriate raw materials, such as steel coils with the desired composition and thickness. The coils undergo various manufacturing stages, including cutting, shaping, and forming, to achieve the desired dimensions and shapes. Specialized equipment and machinery guarantee precision and accuracy throughout the production process. Quality control plays a crucial role in handling custom orders. Manufacturers conduct thorough inspections and testing procedures at different stages of production to ensure that the custom coils meet the customer's specifications and industry standards. This involves checking for dimensional accuracy, surface finish, mechanical properties, and other specific requirements. Third-party inspection agencies may be involved, and manufacturers may provide customers with test reports and certifications to ensure quality assurance. Lastly, once the custom steel coils are manufactured and pass all quality checks, they are meticulously packaged and delivered to the customer. Manufacturers ensure proper packaging and shipping methods to prevent damage during transit and ensure the coils reach the customer in optimal condition. In summary, steel coil manufacturers handle custom orders by collaborating closely with customers, designing and engineering specialized coils, maintaining quality control throughout the production process, and delivering the custom coils to the customer's satisfaction. This systematic approach enables manufacturers to meet the unique requirements of each customer and provide high-quality custom steel coils.

- Q: what is the refining process doing to raw materials in steel

- The refining process removes impurities. Impurities are anything that is not iron (Fe). Most steels are at least 98% iron, with a fraction of a percent of carbon, a dash of manganese, and traces of sulphur and phosphorus. These are called carbon steels. The non-iron elements are impurities found with the iron in the ore. A certain amount of carbon and manganese is beneficial to the strength of steel, so part of the refining process is designed to control the carbon and manganese content to give desired properties to the steel. Sometimes small amounts of these are added in the process. Besides the common carbon steels, there are many alloys of steel in use today. Alloying is done after the steel is refined to over 98% iron, and while it is a liquid. Various elements are added to the steel in controlled amounts to give it special properties. These include silicon, aluminum, magnesium, vanadium, beryllium, nickel and chromium, and sometimes molybdenum, tungsten and titanium. Alloy steels are still mostly iron, ususally at least 95%, but some stainless steels are only 75% iron because of large amounts chromium and nickel added to the mix.

- Q: How do steel coil manufacturers handle international shipping requirements?

- Steel coil manufacturers handle international shipping requirements by ensuring that their products meet the necessary standards and regulations for transportation. This includes adhering to specific packaging requirements, such as utilizing appropriate containers and securing the coils to prevent damage during transit. To meet international shipping requirements, manufacturers also need to comply with customs regulations and documentation. They must prepare accurate and complete paperwork, including commercial invoices, packing lists, and bills of lading, to facilitate smooth customs clearance procedures. Moreover, steel coil manufacturers often work with freight forwarders or shipping agents who specialize in international logistics. These professionals have extensive knowledge of shipping regulations, routes, and carriers, and can assist in arranging transportation, negotiating freight rates, and handling all necessary paperwork. Manufacturers may also opt to use intermodal transportation, which involves utilizing multiple modes of transportation, such as trucks, trains, and ships, to transport their steel coils. This allows for more efficient and cost-effective shipping, especially for long-distance or international shipments. Additionally, steel coil manufacturers may consider insurance coverage to protect their products during transit. Insurance can provide financial compensation in case of any damage, loss, or delays during the shipping process. Overall, steel coil manufacturers handle international shipping requirements through careful planning, compliance with regulations, collaboration with experts in logistics, and consideration of various transportation options. This helps ensure that their products reach international destinations safely, on time, and in compliance with all relevant regulations.

- Q: So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- sure, if the volume of air is about 7 times the volume of steel, the specific weight of the steel/air system would be below 1.0 and it will float. How do you think ships float?

- Q: Is there a difference between hot rolled and cold rolled steel coils?

- Yes, there is a difference between hot rolled and cold rolled steel coils. Hot rolled steel coils are produced at high temperatures and have a rough, scaled surface with slightly rounded edges. They are generally used for applications that require less precise dimensions and a rougher surface finish. On the other hand, cold rolled steel coils are produced at room temperature and have a smoother surface with tighter tolerances and sharper edges. They are commonly used for applications that require precise dimensions, a smoother finish, and higher strength.

- Q: I am about to do a welding project and we are instructed to only use mild steel. I want to use found objects like coins, spoons, bottle caps, screws, and other small fasteners. Are these mild steel? What other objects can I use that are mild steel?

- Mild steel is what your friends get when they see your mom's cleavage.

Send your message to us

Prepainted aluminum Zinc rolled Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords