Prefab House Concrete Purline Casting Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefab House Concrete Purline Casting Mould

1. Structure of Prefab House Concrete Purline Casting Mould:

Prefab House Concrete Purline Casting Mould is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Prefab House Concrete Purline Casting Mould:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

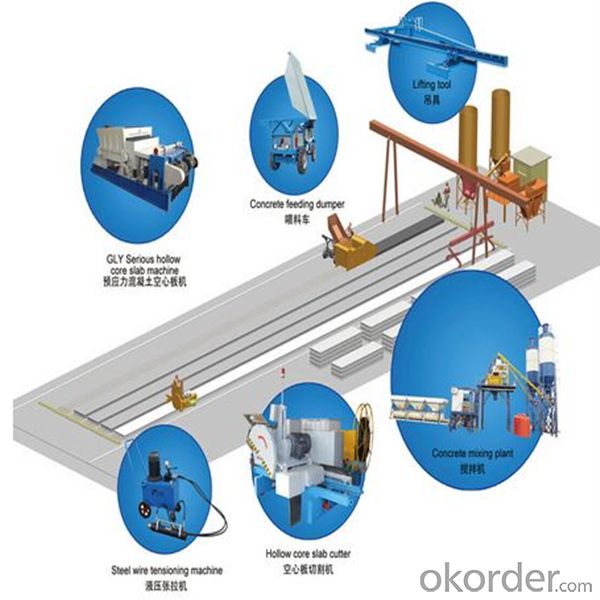

3. Prefab House Concrete Purline Casting Mould Images:

4. Prefabricated Concrete Purline Compression Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

Production Process

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Our Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the <Chinese Prestressed Concrete Hollow Core Slab Standard>.

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: ....i should just glue my mouth shut...

- good one . . . i think :)

- Q: I am tired of politics and politicians and tired of liars with silky tongues merely seeking power and not in the best interests of the people.

- OK, the system SUX! so, now with that settled What do we do? Destroy the present system and leave a vacuum so that any despot can jump in and take control? .... or?

- Q: Is religion like a horse drawn vehicle, doggedly trudging along, refusing to update its machinery?

- Not the Abrahamic religions. The God Yahweh wrote the scripture that these religions evolved from from His advanced scientific knowledge for them to follow for eternity. They are still more advance today then we realize because of us unintentionally falsely interpreting the true meaning of this scripture and giving it the non-scientific religious translation that we still use today and think is out dated but in reality it is us who are still out dated and not the mentioned scripture..

- Q: would these include non motorized equipment used for processing?

- Farm machinery includes such things as tractors, combines, and so on. There are still amish that use non motorized equipment.

- Q: Each part adds to the length of each item. There are 2 parts with a length of 3/4 inches, and 3 parts with a length of 1 5/8.What is the total length of machincery?a) 1 1/4 in b) 4 7/8 in c)5 1/8 in d)6 3/8in

- D

- Q: Any web site could get free machinery manual?

- actually, okorder /... Cheers nb: please visit my web site

- Q: Where can I sell used printing machinery and equipment online?

- OKorder

- Q: i want to sell a candle an unused candle extruder i bought couple of years ago, which internet sites can help me do that?

- Goto okorder

- Q: Hey, so I'm currently working on business coursework. We need to create a made up a business and i have chosen one of those businesses that print peoples picture on to items such a t-shirts, coasters mugs etc.. On one section i need to talk about the equipment and machinery i will need and to be honest i have no idea! could anybody give me a list of them?

- We are a company in heat transfer machine ,we can provide complete solution .you contact me on skype : c0400225

- Q: What are the effects of heat treatment on the mechanical properties of metallic materials

- Hardness, improve processing performance; eliminate internal stress, stabilize the size and reduce the quenching deformation and cracks.

Send your message to us

Prefab House Concrete Purline Casting Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches