Automatic Concrete Column Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Concrete Column Forming Machine

1. Structure of Automatic Concrete Column Forming Machine:

Automatic Concrete Column Forming Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Automatic Concrete Column Forming Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

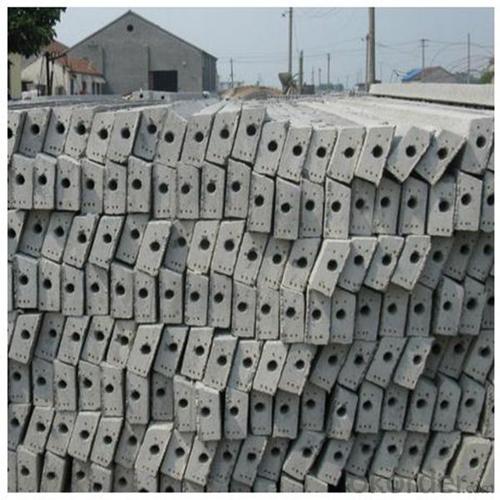

3. Automatic Concrete Column Forming Machine Images:

4. Prefabricated Concrete Purline Compression Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

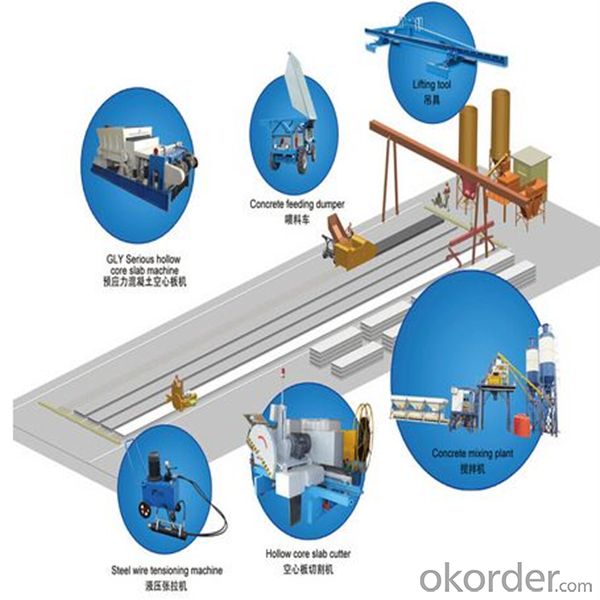

Production Line Layout

Process Flow

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the <Chinese Prestressed Concrete Hollow Core Slab Standard>

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: what products does Zhengzhou Dayu machinery Co.,LD Produce?

- Hi, okorder /

- Q: Machinery was purchased for $51,000 on January 1, 2009. Freight charges amounted to $2,100 and there was a cost of $6,000 for building a foundation and installing the machinery. It is estimated that the machinery will have a $9,000 salvage value at the end of its 5-year useful life. What is the amount of accumulated depreciation at December 31, 2010, if the straight-line method of depreciation is used? $10,020. $8,580. $17,160. $20,040.

- $20,040: (51,000+2,100+6,000-9,000) / 5 = 10,020 per year 2009 - 10,020 2010 - 10,020 Total = $20,040

- Q: I forgot :DI think it's some sort of generator - I know there is some piece of equipment or machinery that converts the energy in power plants...Thanks in advance!!

- Yes its called a generator. It consists of a large magnet in a coil, moving hte magnet creates a current in the coil through induction.

- Q: Each part adds to the length of each item. There are 2 parts with a length of 3/4 inches, and 3 parts with a length of 1 5/8.What is the total length of machincery?a) 1 1/4 in b) 4 7/8 in c)5 1/8 in d)6 3/8in

- D

- Q: I hate working out in public gyms and exorcise rooms if other people are there for some reason. And I hate running in public (I've ran at night before, but now I don't have any time with so much schoolwork). I was wondering what some good exorcises i can do at home every day that don't take long but will make a difference. I was hoping to work my stomach muscles more so i can get in shape for swimsuit season. Thanks! (:

- brisk okorder

- Q: 2004Jan. 1 Paid $106,600 cash plus $6,400 in sales tax for a new machine. The machine is estimatedto have a six-year life and a $9,800 salvage value.Dec. 31 Recorded annual straight-line depreciation on the machinery.2005Dec. 31 Due to new information obtained earlier in the year, the machine’s estimated useful life waschanged from six to four years, and the estimated salvage value was increased to $13,050.Recorded annual straight-line depreciation on the machinery.2006Dec. 31 Recorded annual straight-line depreciation on the machinery.Dec. 31 Sold the machine for $25,240 cash.RequiredPrepare journal entries to record these transactions and events.

- Jan. 1 Paid $106,600 cash plus $6,400 in sales tax for a new machine. The machine is estimated to have a six-year life and a $9,800 salvage value Dr Machinery $113,000 Cr Cash $113,000 Dec. 31 Recorded annual straight-line depreciation on the machinery Dr Depreciation expense $17,200 (i.e. [$113,000-$9,800]/6) Cr Accumulated depreciation $17,200 2005 Dec. 31 Due to new information obtained earlier in the year, the machine’s estimated useful life was changed from six to four years, and the estimated salvage value was increased to $13,050. Recorded annual straight-line depreciation on the machinery Dr Depn $27,583.33 Cr Accum. depn. $27,583.33 (Nbv of $95,800 - 13,050 divided by 3 remaining yrs) 2006 Dec. 31 Recorded annual straight-line depreciation on the machinery Dr Depn $27,583.33 Cr Accum. depn. $27,583.33 (Nbv is now $113,000 - $17,200 - $27,583.33 - $27,583.33 = $40,633.34) Dec. 31 Sold the machine for $25,240 cash Dr Cash $25,240 Dr Loss on disposal of machinery $15,393.34 Dr Accum. depn. $72,366.66 Cr Machinery $113,000

- Q: I have a chance to get a machiery sales job (territory representative for heavy machinery equipoment sales).Since i had no much experience in this domain, i was hoping that somebody can give me tips (general tips) on how to do first sales calls and visits?How should i present myself and how to avoid sounding like telemarketer :)

- try craigs list

- Q: ok someone help me how much is it for all the machinery to biuld a electric car its for my school project that we have to present to the UofA

- Hobbyists okorder

- Q: What would happen if machinery is sold for less than book value?

- Short answer, you have a book loss. Long answer, first we can make no tax assumptions here, not enough info. But for book value, I assume you mean the value on the books of whoever owned it before the sale. If you sell something for less than than the value on your books, you have a book loss. For instance, you bought a computer for $900, intending to keep it for 3 years. After the end of the first year, after a full year depreciation (straight line), the book value is $600. Let us say Dell comes out with something totally new and you want it. You buy it and want to get rid of your old one. But because of the new Dell almost everyone is buying, nobody really wants yours. You find someone to buy it for $200. Your book value was $600, you sold it for $200. You have a loss of $400. On your books is $900 debit to equipment and $300 credit to accumulated depreciation. So your entry to post the sale of your computer is this (Dr is debit, Cr is credit): Dr Cash $200 Dr Accumulated Depreciation $300 Dr Loss on Sale of Asset$400 Cr Computer $900 The entry balances.

- Q: I have fat thighs but don't want to buy expensive machinery what do i do?

- Go for a walk - two miles 5 days out of 7 days each week

Send your message to us

Automatic Concrete Column Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords