Pre-stressed Concrete Slabs Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-stressed Concrete Slabs Making Machinery

1. Structure of Pre-stressed Concrete Slabs Making Machinery:

Pre-stressed Concrete Slabs Making Machinery works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Pre-stressed Concrete Slabs Making Machinery:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

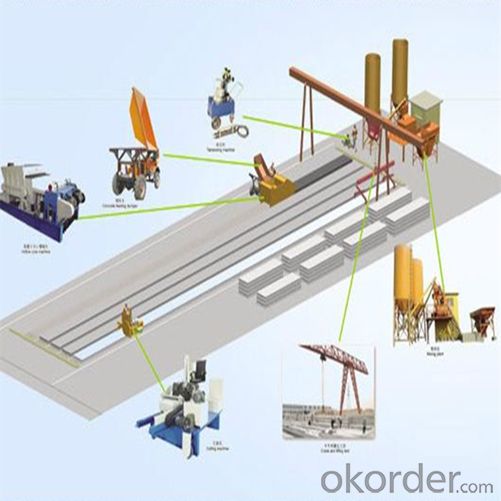

3. Pre-stressed Concrete Slabs Making Machinery Images:

4. Pre-stressed Concrete Slabs Making Machinery Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: it has for wheels and u can move around int it .... i can not think of its name!! PLEASE HELP =0

- Everybody is right; a gantry is called a cherry-picker sometimes. A scissor lift is another kind of mobile people-lifter. I saw a bulb changer driving down the hall changing lights on the high ceiling with a scissor lift. The guy changing street lamps was riding a cherry picker. Pick the one that fits the job.

- Q: Is machinery still being built?

- yes it is

- Q: Details of Plant Machinery for Essential oil from medicines?

- Here okorder /

- Q: Have you ever driven heavy machinery like a fork lift?

- Nope.

- Q: I know the basics - clear cut the trees, put explosives in the mountains, blow the mountain up, separate coal from waste, fill up valleys and then plant some grass. What I want to know if more about the machinery used - some sites talk about a quot;dragline,quot; but don't have any more info than quot;it is used in MTRquot; What kind of explosives are used? How do they gather/separate the coal from the mining waste?

- The explosive is a slurry of Diesel fuel and potassium nitrate that is pumped into the drilled holes for surface mining. They use Semtex and variations of it to do underground mining because of how fast the explosion is. As far as separating there is a very small amount of other materials when you are mining coal. It exists in large quantities at a pure rate. There is almost no need to separate anything from the haul.

- Q: i'm a Taiwan heavy industry and science instrument field agent. i hope i can use this website to contact factory owner to agent ther'e product.

- Best of Luck.

- Q: Needing to know if you have elevator equipment in the back part of an office downstairs in the basement, is there anything put out by this equipment that can cause sickness?

- no i have no idea

- Q: Material processing technology and machinery manufacturing What is the relationship

- Process: In the production process, where the direct change in the size of the object, shape, nature (physical properties, chemical properties, mechanical properties) and the relative position of the process, collectively referred to as the process. Such as rough manufacturing, machining, heat treatment, surface treatment and assembly, it is the main process of production, other processes known as the auxiliary process. Mechanical processing process: the mechanical processing methods, directly change the rough shape, size and surface quality, making it a product part of the process known as the mechanical processing process.

- Q: What can I talk about in my agriculture machinery speech?

- Well...it wouldn't be popular, but it would be eye opening. You could talk about how the tractor companies took draft horses as down payment when they first started up decades ago. The draft horses were then sent off immediately for slaughter. In just a few short years, thanks the the coordinated work by the tractor companies the numbers of available draft horses plunged. That meant that farmers who were unhappy with their tractors, and wanted to go back to using draft horses (or draft mules) were unable to find any for love nor money. That was the beginning of the enslavement to debt of the U.S. farmer. Instead of running a horse that could reproduce itself, farmers now had to go into debt to buy tractors. It meant they worked longer hours (headlights on tractors) to pay for them. No longer did farmers work sun-up till sun-down. Agriculture quickly became a 24 hour a day job. Since the tractor didn't need time to rest, like a horse, it meant longer hours, and purchasing more land (more debt) for the farmer to pay for all the new tractors, and fertilizers that were being pushed on the farmers by agra business companies. Like I said, not a popular speech, but very factual, and something few people realize (even farmers). ~Garnet Permaculture homesteading/farming over 20 years

- Q: Poll : Can you drive big machinery?

- Does a 155mm self propelled howitzer qualify as big machinery? Drove one while I was in the Marines, it weighed in at 28 tons fully loaded with shells and other stuff. The other piece of big machinery I drove was a M55 5 ton multi-fuel 6x6 truck with a ring mounted M2 .50 machinegun. Driving forklifts, skytraxs and sissorlifts seemed sort of tame after that.

Send your message to us

Pre-stressed Concrete Slabs Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords