Pre-stressed Concrete Floor Slabs Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-stressed Concrete Floor Slabs Making Machine

1. Structure of Pre-stressed Concrete Floor Slabs Making Machine:

Products of this series (non-circular and circular cored) are the ideal machines for making building materials on constructions of large span and heavy load bearing in factories, schools, hospitals, shopping centers, office building and homes.

Our hollow core slab machines have the advantages of reasonable design, easy operation, convenient maintenance and long working life. Slab length can be achieved to 4.2m to 18m; width of 600mm, 900mm and 1200mm; thickness of 120mm, 150mm, 180mm, 200mm, 250mm, 300mm, 380mm.

The hollow core slab machines are working on the long-line table, tensioning the high-strength and low-relaxation steel strand first, and using the pushing work method to form the concrete hollow core slab. The slabs which being formed have the advantages of smooth surface and high-density structure.

2. Main Features of Pre-stressed Concrete Floor Slabs Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

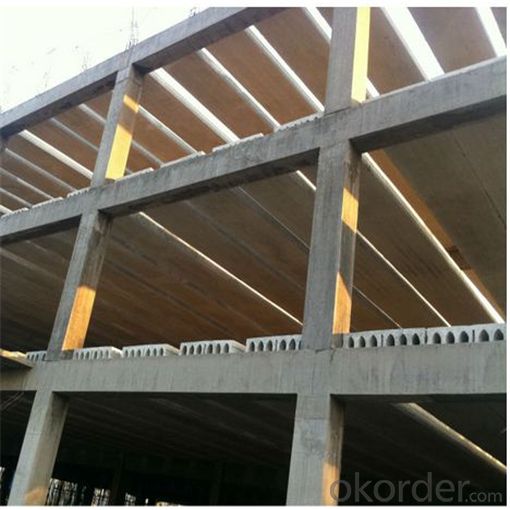

3. Pre-stressed Concrete Floor Slabs Making Machine Images:

4. Pre-stressed Concrete Floor Slabs Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: what are the auxiliary machinery found in ships?

- It's not that I think this kind of teaching should continue, but it would be a shame to have to repeat the course. I'm not sure what the school administration would decide. (It is a really bad test. I know nothing about your subject, but it is very hard to read and understand).

- Q: I found one in italy. that says our machinery for beverages:-filling,-dosing, -rinsing machines, -labeling, -bending, -capping machines,-packaging and conditioning machinery, -automatic corking machines,-sterilizations sysytems i wanna know what these ^ mean to explain each of them basically and their functions for the beverage machinery.. plz help !!!!!!!!!!!!

- hh

- Q: Royal Co. acquired new machinery with a list price of $700,000. At the date of Purchase they received a $7,000 cash discount and paid $2,000 of delivery charges. Installation and worker training costs were $46,000 and $14,000 respectively. During installation, worker negligence caused $15,000 damage to other machinery in the factory building. What is the acquisition cost for the machinery?I am unsure what to include, deduct or add in the calculation. Any help would be great!

- Acquisition Cost Accounting

- Q: I remember a famous economist said that. Poor countries are economically advantaged to use manual labor instead of advanced technology so that they can employ everyone.

- If that's a famous economist, he's a stupid, famous economist. Pure poppycock. Productivity matters. That famous economist failed Econ 101. Is it leftist darling Paul Krugman? The guy who ignored the basic fact that all wealth destruction is bad and declared the 9/11 rebuilding in NYC a positive economic event?

- Q: If the machinery that accomplishes X-chromosome dosage compensation in humans was defective (e.g., 1 protein was mutant), what do you expect the consequences would be? Choose one. a) no consequences b) XX embryos would not be viable c) XY embryos would not be viable d) both XX and XY embryos would not be viable

- B

- Q: would these include non motorized equipment used for processing?

- Farm machinery includes such things as tractors, combines, and so on. There are still amish that use non motorized equipment.

- Q: ok someone help me how much is it for all the machinery to biuld a electric car its for my school project that we have to present to the UofA

- Hobbyists okorder

- Q: When a virus takes over the machinery of a cell, it forces the cell to manufacture:a. more mitochondria to provide energy for the virus b. more lysosomes for digestion c. more food particles d. more virus particles

- D. Look up the experiment done by Hershey and Chase. In their experiment, they used bacteriophages - viruses that attack bacteria.

- Q: Reconditions will do, will need some for places with dire needs

- The okorder /

- Q: What are the effects of heat treatment on the mechanical properties of metallic materials

- Normalizing: low carbon steel can improve the cutting performance, can refine the grain, improve the comprehensive mechanical properties.

Send your message to us

Pre-stressed Concrete Floor Slabs Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords