Pre-Painted Galvanized Steel Sheet/Coil , High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized Steel Coil Images

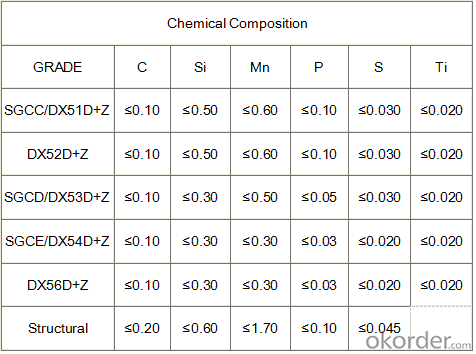

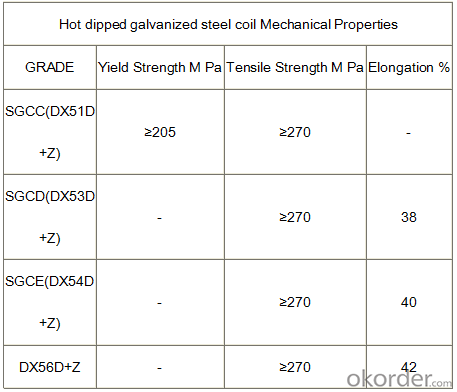

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Suppose you made a sword out of diamond (just follow me here, it's only theoretical). Would it be lighter than a sword of the same size made out of steel?

- steel is heavier. 6.5 mm/1 carat of steel is 7 grams, while diamond is 1/5 a gram

- Q: What are the different types of steel coil slitting lines?

- In the metal processing industry, various types of steel coil slitting lines are utilized to cut large coils of steel into narrower strips for different applications. 1. Loop Slitting Lines: The industry commonly employs loop slitting lines, which consist of a decoiler to hold the coil, a slitter head for cutting the coil into strips, and a recoiler to wind the strips into smaller coils. These lines are versatile and can handle different coil widths and thicknesses. 2. Scrap Chopper Slitting Lines: Similar to loop slitting lines, scrap chopper slitting lines incorporate a scrap chopper unit. This unit eliminates excess material from the coil edges before slitting, enhancing efficiency and reducing waste. 3. Double Loop Slitting Lines: For high-speed slitting of thin-gauge coils, double loop slitting lines are utilized. These lines feature two looping pits, enabling continuous operation. While one coil is processed, the other is prepared for slitting, minimizing downtime. 4. Turret Head Slitting Lines: Designed for high-volume production, turret head slitting lines can process multiple coils simultaneously. They are equipped with a turret head containing multiple slitter knives that can be swiftly rotated to switch between different coil widths, resulting in faster and more efficient production. 5. Rotary Shear Slitting Lines: Rotary shear slitting lines are suitable for thicker and harder materials. Instead of a slitter head, they employ a rotary shear to cut the coil into strips. The rotary shear offers improved cutting performance and can handle higher tensile strength materials. 6. Combination Slitting Lines: Combination slitting lines are versatile machines that can handle various materials and perform both slitting and cut-to-length operations. They are ideal for smaller manufacturers or those requiring flexibility in their production process. Ultimately, the choice of steel coil slitting line depends on the manufacturer's specific requirements, including the type of material, desired strip width, and production volume.

- Q: I own a crappy steel string acoustic and a very nice electric guitar.I have saved up to buy a new acoustic but I cannot decide to just invest in a better steel string or explore around with a nylon string. From others experience, will I get my fill of satisfaction of playing on a nylon, or should I stick to a steel string?

- Nylon is easy to use for beginners but steal sounds better.

- Q: My remington has a 28 inch barrel and was wondering if it would damage my shotgun to shoot steel out of it?

- Yes, OK for steel. Like Mr. 357 says, with steel shot one size more open is equal to the one size tighter. So the Modified should shoot like a full choke and your improved cylinder should pattern like a modified choke. The Express model came out about the same time steel shot became prevalent and it is fine with steel shot. If I remember correctly we were working on making the data sheets for steel shot around 1988-1989. My hunting buddy and neighbor was the man who first began importing steel shot. Had to figure out a wad to use with it also. And got it Federally mandated for waterfowl hunting.

- Q: Is 440 steel relatively strong or weak?

- Its strong steel is rated by the precence of carbon in it. Higher carbon _ higher the price

- Q: This question is directed to anyone who has played or know someone who plays a lap or pedal steel guitar.I've been a guitarist for about 8 years now and have played a variety of styles from rock, fingerstyle/classical, singer/songwriter acoustic stuff, ect, and now I've really had an interest in learning how to play a lap steel or pedal steel guitar. I am completely new to the instrument(s), so I'm seeking all the information I can. I do know that a pedal steel is a lot more expensive, so I'm probably looking to start on a lap steel for now. Basically how should I get started? Should I find a cheap lap steel at a pawn shop or purchase something new? Are there any good method books out there? I'm a pretty experienced guitarist, so should I expect to get the hang of it quickly? Is there much of a market for a lap/pedal steel player? haha.Also, I am left handed. How much trouble would it be to re-string a steel guitar? Or would I be better off getting a left-handed model?

- Hi, okorder /

- Q: I have several stainless steel utensils and appliances, so when I put them through the dishwasher some of them are rusting, I think its because my current dishwashing soap is harsh, what is some great dishwashing soap that will clean my dishes and not be so hard on my stainless steel appliances and utensils?

- Jan is correct. You need to have some nickel in the stainless steel to prevent rusting, like 18/10 which has 10% nickel alloy in the steel.

- Q: How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they provide a crucial component for generating and transmitting electric currents. These coils, made of high-quality steel, are used in a variety of applications such as transformers, motors, generators, and electromagnets. The steel coil's magnetic properties allow it to efficiently conduct and amplify electrical currents, making it an essential component in the overall functioning of electrical systems.

- Q: I would like to buy a new cold steel recon 1 folding knife. My concern is the knife is made in Taiwan, will the quality of blade/overall make is lower quality compare with those made in US/JAPAN? The plan is use as an EDC, any good suggestion with similar style? Most important to me is reliability, 2)sharpness, 3) maintance than 4)cost. Anyone can point me into right direction? Please share, Thanks in advance.

- I recently bought the same weapon and am really impressed. There is no decline in quality and it arrived sharp enough to shave with. I rank upon the finer knives that I own. I would not hesitate to use it in a defensive situation (or offensive).

- Q: How did the growth of the steel industry influence the development of other industries?

- At least three ways: 1. Steel as a material that other industries could use to do things that couldn't be done before (for example, construction (skyscrapers, long bridges, etc.)) or could now be done at much lower cost and hence increased the size of the industry (automobiles, bearings, etc.)

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil , High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords