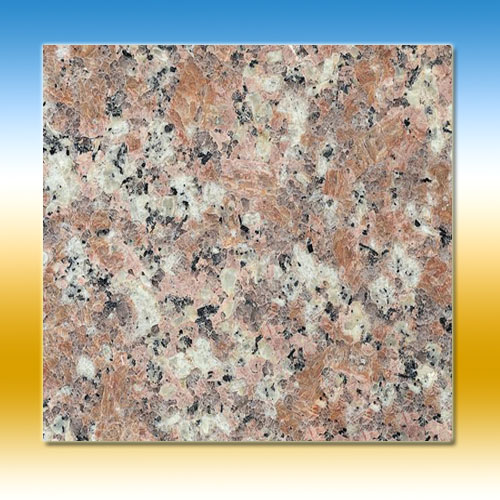

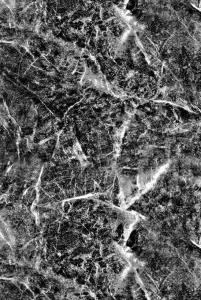

Pre-painted Galvanized Steel Coil-JIS G 3312-stone pattern7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: I have heard using the BRASS casing is the best thing for an AR-15? Should i just use Brass or Steel?

- Many people have to jam a cleaning rod muzzle end first, using a hammer to bang out steel cased ammo out of an Ar rifle. This has happened to me 3 times and will Never happen again. It said its harder on the extractor, well that is not so but the case will be badly damaged by the extractor and I don't think that is a good thing for any extractor. Any individual pushing steel cased ammo must be selling it...Don't Buy It!!!

- Q: How are steel coils used in the production of metal enclosures?

- Steel coils are used in the production of metal enclosures as they provide the raw material needed for forming and shaping the enclosure. The steel coils are processed and cut into sheets or strips, which are then bent, welded, or stamped to create the desired shape and structure of the enclosure. These steel sheets offer strength, durability, and a smooth surface finish to the final product, making them ideal for manufacturing metal enclosures used in various industries such as automotive, electronics, and construction.

- Q: When and where did soldiers wearing steel protective helmets start ?It seems to have been common by the start of WW1

- You okorder /

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and secure manner.

- Q: What are the different coil packaging methods used for steel coils?

- Steel coils can be packaged using various methods to guarantee their protection and secure transportation. These methods also help optimize storage space. Some of the commonly used packaging methods for steel coils are as follows: 1. Strapping: Metal or plastic straps are used to secure the steel coils. This ensures stability and prevents unrolling or shifting during transportation. Strapping is suitable for smaller coils or when other packaging methods are also utilized. 2. Stretch wrapping: Steel coils are tightly wrapped using a stretch film. This technique provides excellent protection against dust, moisture, and other contaminants. It also keeps the coils tightly bound and prevents movement during handling and transportation. 3. Steel banding: Steel bands or straps are employed to secure the coils. This packaging method offers superior strength and durability. It is ideal for larger and heavier steel coils that require additional reinforcement. 4. Wooden crating: Particularly large or heavy steel coils are packaged in wooden crates. These crates provide enhanced protection against impacts, moisture, and other external factors. Wooden crating is commonly used for long-distance transportation or when coils need to be stored for extended periods. 5. Coil saddles: Specialized devices called coil saddles are used to package large coils securely. These devices prevent rolling or movement. Coil saddles are preferred when strapping or wrapping is not feasible. 6. Paper interleaving: Sheets of paper are placed between each layer of steel coils to prevent damage caused by friction. This method is commonly used for coils with a high surface finish or those susceptible to scratching. Each of these packaging methods offers distinct advantages and is chosen based on factors such as coil size, weight, transportation requirements, and desired level of protection. By employing these methods, steel coil manufacturers and distributors can ensure the safe arrival of their products in optimal condition.

- Q: What are the challenges in coil recoiling?

- Coil recoiling, also known as coil winding, can pose several challenges depending on the specific application and requirements. Some of the common challenges in coil recoiling include: 1. Precision and accuracy: Achieving precise and accurate winding is crucial for optimal coil performance. Maintaining consistent tension throughout the winding process, ensuring proper alignment, and controlling the speed are essential to avoid variations in the coil's electrical properties. 2. Wire management: Handling the wire during the recoiling process can be challenging. The wire may be delicate, prone to tangling, or have specific handling requirements, such as being magnetically or thermally sensitive. Proper wire management techniques, such as tension control, wire guide systems, and spooling mechanisms, need to be employed to prevent wire damage and ensure uniform winding. 3. Space constraints: In many applications, coils need to fit within specific space limitations. Designing and winding coils to fit compact spaces can be challenging, especially when considering the required number of turns, wire size, insulation, and any additional components or structures that may need to be incorporated. 4. Material selection: Selecting the appropriate wire and insulation material is crucial for coil performance and longevity. Factors such as electrical conductivity, thermal properties, mechanical strength, and chemical resistance need to be considered to ensure the coil can withstand the operating conditions and environmental factors it will be exposed to. 5. Heat dissipation: Coils often generate heat during operation, especially in high-power applications. Efficient heat dissipation is essential to prevent overheating and ensure the longevity of the coil. Designing the coil with proper ventilation, utilizing cooling mechanisms, or integrating heat sinks are some of the techniques used to address this challenge. 6. Quality control: Ensuring consistent quality in coil recoiling can be challenging due to factors such as variations in wire properties, operator skill, equipment calibration, and environmental conditions. Implementing robust quality control measures, such as conducting regular inspections, performing electrical tests, and monitoring process parameters, is necessary to maintain consistent coil performance. Overall, coil recoiling requires attention to detail, precision, and adherence to specific requirements to overcome the challenges and produce high-quality coils that meet the desired performance criteria.

- Q: How are steel coils loaded onto trucks or containers?

- Steel coils are typically loaded onto trucks or containers using specialized equipment such as coil lifters or coil hooks. These devices safely secure the coils and allow them to be lifted and positioned onto the truck or container. The coils are then secured in place using straps or other restraints to prevent them from shifting during transportation.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored and transported in a horizontal position, either on the ground or on specially designed racks. They are often secured with steel straps or bands to prevent movement or damage during transportation. When being transported, steel coils are typically loaded onto flatbed trucks or shipping containers using cranes or forklifts. The coils are then secured in place with additional straps or chains to ensure stability during transit.

- Q: What is the role of steel coils in the production of appliances?

- The role of steel coils in the production of appliances is to provide a strong and durable material for the construction of various components and structures. Steel coils are commonly used to manufacture appliance parts such as panels, frames, cabinets, and internal components. The high strength and versatility of steel make it ideal for withstanding the stress and demands of everyday appliance use. Additionally, steel coils can be shaped, molded, and welded to create customized designs and configurations, ensuring the appliances are both functional and aesthetically pleasing.

- Q: What is the shelf life of steel coils?

- Various factors, such as the type of steel, its specific application, and the storage conditions, can affect the shelf life of steel coils. Generally, steel coils have a lengthy shelf life due to their durability and resistance to corrosion. When stored correctly in a dry and controlled environment, steel coils can maintain their quality for many years. It is important to consider that certain types of steel, like galvanized steel, may have a shorter shelf life if the protective coating is compromised and corrosion occurs. Additionally, exposure to extreme weather conditions, high humidity, or chemicals can reduce the shelf life of steel coils. To ensure the longevity of steel coils, it is advisable to store them in a covered area to protect them from moisture and direct sunlight. Proper stacking and handling techniques should also be employed to prevent any damage that could lead to premature deterioration. In conclusion, the shelf life of steel coils can vary, but with appropriate storage and handling, they can remain in good condition for an extended period. This makes them a reliable and long-lasting material for various applications.

Send your message to us

Pre-painted Galvanized Steel Coil-JIS G 3312-stone pattern7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords