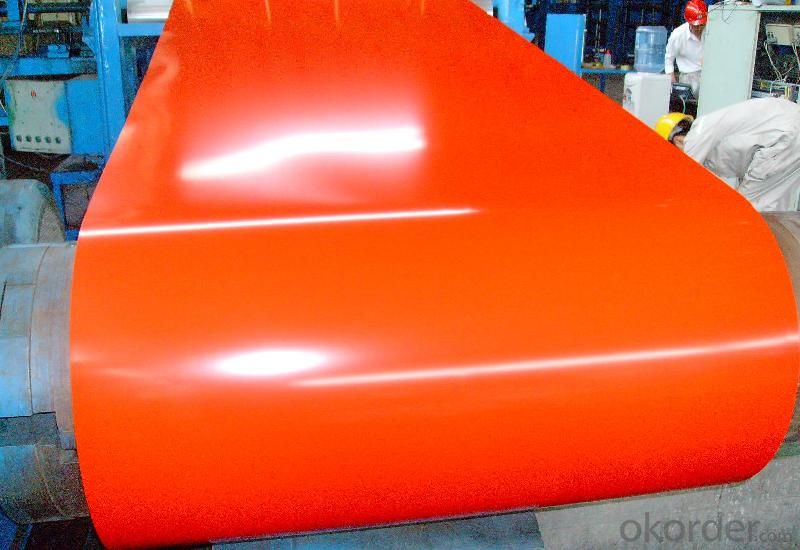

Pre-painted Galvanized Sheet Coil with Good Quality in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

• Good formability

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirementsPaint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

8Zinc coating: 60-275G/M2, both sides

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

How to guarantee the quality of the products?

We have established the international advanced quality management system,We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

PPGI steel is good capable of decoration, molding, corrosion resistance. finally the plate steel is called pre-painted galvanized (aluzinc) steel.

It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• good corrosion resistance • perfect weather resistance • Excellent corrosion resistance • High strength

- Q: How are steel coils inspected for surface finish?

- Steel coils are typically inspected for surface finish using visual inspection techniques and specialized equipment such as surface roughness testers, gloss meters, and profile scanners. These methods help to assess the coil's smoothness, texture, and appearance, ensuring it meets the required surface finish specifications.

- Q: What are the challenges in coil leveling for coated steel?

- Coil leveling for coated steel presents several challenges due to the additional layer of coating. Firstly, the coating can be sensitive to pressure and friction, making it prone to damage during the leveling process. Maintaining the integrity of the coating while achieving the desired flatness of the steel is a delicate balance. Additionally, the thickness of the coating can vary across the coil, leading to uneven leveling results. The choice of leveling equipment and parameters must be carefully determined to minimize coating damage and ensure consistent flatness throughout the coil. Moreover, the presence of coating can impact the accuracy of leveling measurements, as it may interfere with the sensors or affect the readings. These challenges require careful attention and expertise to successfully level coated steel coils while preserving the quality of the coating.

- Q: What are the typical coil thickness options?

- The typical coil thickness options vary depending on the specific application and industry. However, common coil thickness options range from 0.005 inches (0.13 mm) to 0.250 inches (6.35 mm).

- Q: The strip tower height

- Causes: the strip has a larger snake shape; the take-up device holds the tension; the setting is unreasonable; the strip goes into the coiler; the centering is not good; the coil tension is not set properly.

- Q: What are the different types of coil slitting machines?

- There are several different types of coil slitting machines available in the market, each designed to meet specific requirements and preferences. Some of the common types include: 1. Rotary shear slitters: These machines use rotary knives mounted on a rotating drum to cut the coil into narrow strips. They are ideal for high-speed operations and can handle large volumes of material. 2. Loop slitters: Loop slitting machines feed the coil through a loop to maintain tension and prevent material damage during the slitting process. They are suitable for delicate materials or those prone to deformation. 3. Turret slitters: Turret slitting machines have multiple sets of slitting knives mounted on a rotating turret. This allows for quick and easy changeover between different slitting configurations, reducing downtime and increasing productivity. 4. Drag slitters: Drag slitting machines use a stationary knife and a moving clamp to hold and pull the coil through the cutting process. They are versatile and can handle a wide range of materials, including thick or heavy coils. 5. Crush slitters: Crush slitting machines use a set of opposing rollers to crush and cut the coil material. They are commonly used for softer materials or those that are difficult to cut with traditional knives. 6. Laser slitters: Laser slitting machines use a high-powered laser beam to precisely cut through the coil material. They offer unmatched accuracy and are suitable for high-end applications or materials with complex shapes. Each type of coil slitting machine has its own advantages and limitations. The choice of machine depends on factors such as the type of material, required speed, desired accuracy, and production volume.

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing through visual inspection, magnetic particle inspection, or ultrasonic testing. Visual inspection involves examining the surface for any visible defects such as scratches, dents, or corrosion. Magnetic particle inspection uses magnetic fields and iron particles to detect surface cracks or defects that may not be visible to the naked eye. Ultrasonic testing involves using high-frequency sound waves to detect internal and surface defects in the steel coils. These inspection methods help ensure the quality and integrity of the steel coils before they are further processed or delivered to customers.

- Q: How do steel coils perform in high-pressure applications?

- Steel coils perform well in high-pressure applications due to their inherent strength and durability. The high tensile strength of steel allows it to withstand the intense pressure without deformation or failure. Additionally, steel coils can be manufactured to precise specifications, ensuring they can handle the specific pressure requirements of the application. Overall, steel coils are a reliable and efficient choice for high-pressure applications.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- 154cm is a very good knife steel, the problem is in the heat treating. Stainless should be cryo treated to get all it can offer. That being said, if you really want to drop some coin, look at getting one made from CPM 440V. Stainless isn't as strong as carbon but on a smaller knife works well. You might also look for D-2 Tool steel. There are factory knives that are made of that.

- Q: Why is the steel tape tape head not fixed?

- In this way, no matter how you measure, always be measured, from the ruler of the "0" bit began.The fixed ruler does not take this action when it is taken, which directly results in the thickness of the steel sheet that needs to be added or lowered to your readings;Activity design is designed to reduce error, and this is an advanced approach;

- Q: How are steel coils used in the manufacturing of bridges?

- Steel coils are used in the manufacturing of bridges as they provide the raw material for creating structural components such as beams, girders, and columns. These coils are processed and shaped into the required sections, which are then assembled and welded together to form the bridge's framework. The strength and durability of steel make it an ideal material for constructing bridges that can withstand heavy loads and harsh environmental conditions.

Send your message to us

Pre-painted Galvanized Sheet Coil with Good Quality in Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords