Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

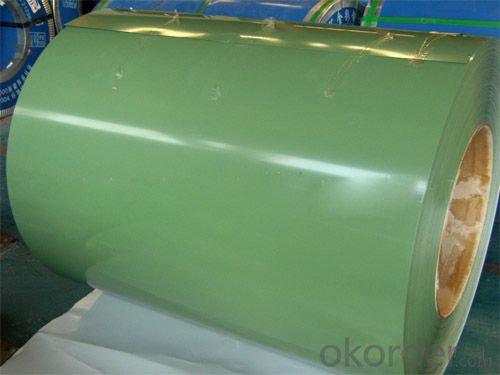

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the maximum temperature resistance of steel sheets?

- The maximum temperature resistance of steel sheets typically depends on the specific grade of steel being used, but in general, most steel sheets can withstand temperatures up to around 1,500 degrees Fahrenheit (815 degrees Celsius) without significant structural damage.

- Q: What is the difference between hot rolled steel and controlled rolled steel plate? Can two plates be used interchangeably?

- Controlled steel plate is called controlled rolling and controlled cooling, referred to as controlled rolling and controlled cooling.

- Q: What are the different methods of surface cleaning for steel sheets?

- Surface cleaning of steel sheets offers various methods, each with its own advantages and applications. 1. Mechanical Cleaning: To physically eliminate dirt, rust, and other contaminants from steel sheet surfaces, one can utilize sandpaper, wire brushes, or abrasive blasting. This approach is ideal for heavy-duty cleaning and preparing surfaces for further treatment or coating. 2. Chemical Cleaning: By employing chemicals or detergents, one can dissolve or remove contaminants from the steel surface. This method is particularly effective in eliminating grease, oil, and other organic substances. It is crucial to select the appropriate chemical cleaner based on the type of contamination and the composition of the steel sheet, ensuring effective cleaning without surface damage. 3. Electrolytic Cleaning: This technique involves submerging the steel sheet in an electrolyte bath along with an electric current to dissolve and separate contaminants. Electrolytic cleaning is effective in removing stubborn rust, scale, and oxidation, while also providing a polished finish. 4. Power Washing: Also known as pressure washing, this method employs a high-pressure water stream to cleanse the steel surface. Power washing effectively removes loose debris, dirt, and mild contaminants. However, it may not be suitable for heavy-duty cleaning or the elimination of stubborn substances like rust. 5. Vapor Degreasing: Vapor degreasing utilizes solvent vapors to clean the steel surface. By exposing the steel sheet to these vapors, contaminants are dissolved and removed. This technique is particularly effective in eliminating oil, grease, and other organic substances. Vapor degreasing is a precise and controlled cleaning method commonly utilized in industrial applications. Before selecting a surface cleaning method, it is crucial to consider the type and severity of contamination, the desired level of cleaning, and the specific requirements of the steel sheets. Additionally, it is important to prioritize safety precautions and utilize appropriate protective equipment when performing any surface cleaning procedure.

- Q: How do steel sheets perform under heavy loads or pressure?

- Steel sheets are renowned for their extraordinary strength and durability, rendering them highly impervious to immense loads or pressure. With their unique composition and manufacturing process, steel sheets possess an elevated tensile strength that empowers them to endure significant amounts of force without distorting or fracturing. This trait renders steel sheets exceptionally well-suited for applications involving substantial loads or pressure, such as construction, transportation, and industrial machinery. Moreover, steel sheets exhibit an exceptional load-bearing capacity, enabling them to evenly distribute applied pressure across their surface, thereby minimizing the likelihood of structural failure or damage. The rigidity of steel sheets further enhances their ability to withstand heavy loads or pressure, preventing them from bending or buckling and ensuring the integrity of the supported structure or equipment. In summary, steel sheets offer a dependable and robust solution for handling heavy loads or pressure, making them a favored material across various industries.

- Q: What are the different cutting methods for steel sheets?

- There are several cutting methods commonly used for steel sheets, including shearing, laser cutting, plasma cutting, waterjet cutting, and abrasive cutting. Each method has its own advantages and suitability depending on the thickness and type of steel, desired precision, speed, and cost considerations.

- Q: Can steel sheets be used for architectural facades?

- Yes, steel sheets can be used for architectural facades. Steel sheets are commonly used in architectural facades due to their durability, strength, and aesthetic appeal. They can be easily formed into various shapes and sizes, allowing for creative and unique designs. Steel sheets can also be finished with different coatings or finishes to enhance their appearance and protect them from corrosion. Additionally, steel is a sustainable material as it can be recycled and reused, making it an eco-friendly choice for architectural facades. Overall, steel sheets offer a versatile and reliable option for architects and designers looking to create visually striking and long-lasting facades.

- Q: Can steel sheets be used for automotive manufacturing?

- Yes, steel sheets can be used for automotive manufacturing. Steel sheets are commonly used in the automotive industry for various applications, including body panels, chassis components, and structural parts. Steel offers excellent strength, durability, and formability, making it a preferred material for automotive manufacturers. Additionally, steel sheets can be easily shaped and welded, allowing for efficient fabrication processes in automotive manufacturing.

- Q: What is the difference between an open plate and an original plate?

- Open and flat from the original flat surface color to distinguish. Because the Kaiping plate originally is rolled strip, the oxide is less, the same time the Kaiping plate and the original flat for a period of time after the original flat in different colors, red, and blue plates.

- Q: What is the difference between a coated and uncoated stainless steel sheet?

- A coated stainless steel sheet is one that has been treated with a protective layer, such as a polymer or paint, to enhance its resistance to corrosion, scratches, and stains. On the other hand, an uncoated stainless steel sheet does not have any additional protective layer, leaving it more susceptible to these issues.

- Q: Can steel sheets be used for decorative wall panels?

- Yes, steel sheets can be used for decorative wall panels. They can provide a modern and industrial aesthetic to a space and offer durability and versatility in design options.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords