Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvalume Steel Coil Description

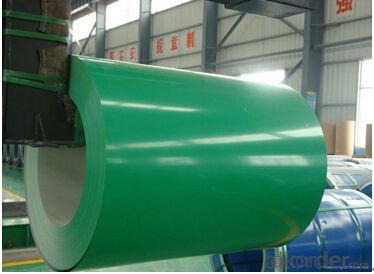

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvalume Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

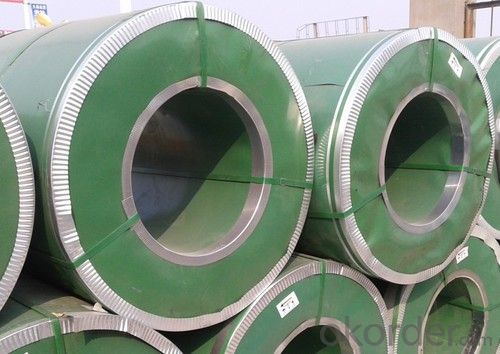

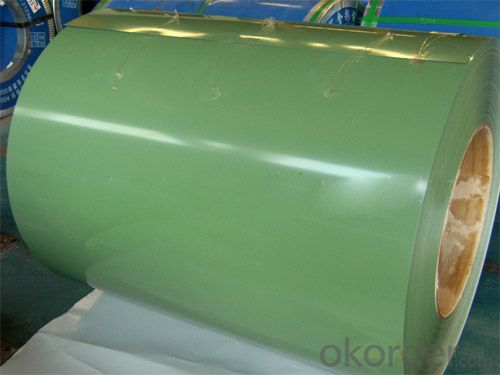

3.Pre-painted Galvalume Steel Coil Images

4.Pre-painted Galvalume Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvalume Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- Steel has more mass.

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: What are the challenges in coil blanking?

- Coil blanking, a process used to cut flat metal sheets from coiled stock, presents several challenges that need to be addressed for efficient and accurate production. Some of the key challenges in coil blanking include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality. These variations can affect the cutting process and result in inconsistent blanks. Proper material selection and control are crucial to ensure consistent quality and dimensional accuracy. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature). These imperfections can cause alignment issues during the cutting process, leading to misalignment and inaccurate blanks. Specialized equipment and techniques, such as straighteners and leveling systems, are required to minimize these shape imperfections. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Adequate edge conditioning techniques, such as deburring or edge trimming, need to be employed to ensure clean and straight edges for the final blanks. 4. Slitting and shearing forces: The forces exerted during the coil blanking process can induce stresses and strains in the material, potentially leading to deformation or springback. These factors can result in dimensional variations and affect the overall quality of the finished blanks. Careful consideration of the slitting and shearing forces, along with proper tooling design and machine settings, is necessary to minimize these effects. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and minimizing material waste are critical challenges in coil blanking to optimize production efficiency and reduce costs. Efficient nesting algorithms and real-time monitoring systems can help optimize material utilization and minimize waste. 6. Automation and productivity: Coil blanking processes often require high-speed and high-volume production to meet market demands. Implementing automation systems, such as robotic material handling and advanced control systems, can enhance productivity. However, integrating and synchronizing these automation components with the cutting process can be challenging and requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking requires a combination of proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: What are the dimensions of steel coils used in the automotive industry?

- The dimensions of steel coils used in the automotive industry can vary depending on the specific application and requirements. However, typical dimensions for steel coils used in the automotive industry range from 0.5mm to 3mm in thickness and from 500mm to 2000mm in width. The length of the coils can vary depending on the production process and customer specifications. Additionally, the weight of the coils can range from a few hundred kilograms to several tons. It is important to note that these dimensions are general guidelines and can vary depending on the specific needs of the automotive manufacturer.

- Q: What are the different methods of shearing steel coils?

- There are several different methods of shearing steel coils, each offering its own unique advantages and disadvantages. Some of the most common methods include: 1. Guillotine Shearing: This method involves using a guillotine-like machine with a blade that moves vertically to cut through the steel coil. Guillotine shearing offers high efficiency and accuracy, making it suitable for large-scale industrial production. However, it may cause deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is used to cut through the steel coil. This method allows for continuous cutting, making it ideal for high-speed production lines. It provides a clean and precise cut, but it requires regular maintenance and sharpening of the blades. 3. Slitting: Slitting involves passing the steel coil through a set of circular blades that make multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers high precision and can produce multiple strips simultaneously. However, slitting may cause edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting uses a high-powered laser beam to melt or vaporize the steel coil along a pre-determined path. This method offers exceptional precision and can cut complex shapes or patterns. It is commonly used for specialized applications where accuracy is crucial, although it can be relatively expensive. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM uses electrical discharges to erode the steel coil and create the desired shape. This method is commonly used for intricate or delicate cutting tasks that require high precision. It is particularly effective for hard materials. Each method of shearing steel coils has its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: i was giving this old knive. the knife part is stainless steel and has a couple rust spots but im not sure that the handle is (i think stainless) but it has this un smooth surface i dont think its rust because its not brown. would rubbing alcohol help clean it?

- stainless steel comes in several different qualities believe it or not. the real good stainless, like marine grade, will probably never rust. but, there are cheaper types of stainless steel with less nickel in them, and they will pit and or rust over time. Alcohol won't work. I would try wd-40 on it. soak a cloth and rub it to polish. if that doesn't work, try wd-40 and a very fine steel wool, like 000 grade, and buff it with the wd-40.

- Q: What are the factors affecting the corrosion resistance of steel coils?

- The factors affecting the corrosion resistance of steel coils include the chemical composition of the steel, the presence of impurities or alloying elements, the surface condition and quality of the coils, the environmental conditions, such as humidity, temperature, and exposure to corrosive substances, and the presence of protective coatings or treatments.

- Q: Is sterling silver better than surgical steel as far as being hypoallergic in earrings? If I have a choice which should I get? Thanks!

- Surgical steel.

- Q: How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

- Q: What are the potential dangers of handling steel coils?

- There are several potential dangers associated with handling steel coils. Firstly, steel coils are heavy and can pose a risk of physical injury if not handled properly. The weight of the coils can cause strains, sprains, or even more serious injuries if dropped or mishandled. This is particularly true when using manual lifting equipment or when attempting to move the coils without proper training or assistance. Secondly, steel coils often have sharp edges or protruding parts that can cause cuts or puncture wounds if not handled with care. These sharp edges can be especially hazardous when attempting to manipulate or position the coils during transportation or storage. It is important to wear appropriate personal protective equipment, such as gloves, to minimize the risk of injury. In addition, steel coils can become unstable if not adequately secured or balanced. Improper stacking or storage of the coils can lead to them shifting or falling, potentially causing serious injuries or damage. It is crucial to follow proper stacking and storage procedures, including using appropriate equipment and supports, to ensure stability and prevent accidents. Furthermore, steel coils are often stored in areas with limited space or uneven surfaces, increasing the risk of trips, falls, or collisions. It is essential to maintain clear and well-organized storage areas, free of obstacles or hazards, to reduce the likelihood of accidents. Lastly, steel coils can be subject to corrosion or rust, which can weaken the metal and compromise their structural integrity. This can increase the risk of the coils collapsing or breaking during handling, potentially causing injuries or damage to property. Regular inspections and maintenance of the coils, as well as proper storage in dry and well-ventilated areas, can help mitigate this risk. Overall, the potential dangers of handling steel coils include physical injuries from their weight and sharp edges, instability during transportation or storage, accidents due to limited space or uneven surfaces, and the risk of structural failure due to corrosion or rust. It is crucial to follow proper safety protocols, receive appropriate training, and use the necessary equipment to minimize these risks and ensure safe handling of steel coils.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords