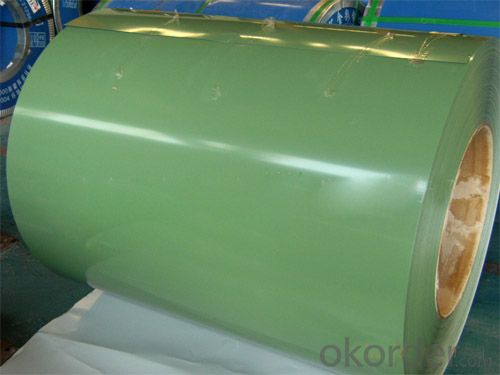

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price color is green

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted GI/GL Steel Coil Images

4.Pre-painted GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I'm looking to buy the Milano Stiletto, and it uses 1045 steel. I was just wondering whether this will hold up and keep an edge.

- 1045 Steel

- Q: Is Ace Steel's wrestling school still running?And do you know if their are any other wrestling schools in chicago?

- the Steel Domain wrestling school thats where cm punk got trained at i live in cleveland but i was in chicago last month and took a tour of the school.

- Q: What are the environmental benefits of using steel coils?

- There are several environmental benefits associated with using steel coils. Firstly, steel is a highly recyclable material. Steel coils can be easily recycled and repurposed into new steel products, reducing the need for mining and extraction of raw materials. Recycling steel also requires less energy compared to producing it from scratch, resulting in lower greenhouse gas emissions and a smaller carbon footprint. Additionally, steel is known for its durability and longevity. When used in construction or manufacturing applications, steel coils can last for decades without losing their structural integrity. This reduces the need for frequent replacements, which in turn reduces the consumption of resources and energy required for production. Furthermore, steel is highly resistant to corrosion and weathering, making it a suitable choice for outdoor applications. This resistance to decay means that steel coils can withstand harsh environmental conditions and maintain their functionality for extended periods. This reduces waste generation and the associated environmental impacts of replacing damaged or deteriorated materials. Lastly, steel is a versatile material that can be used in a wide range of industries and applications. Its versatility allows for efficient use of resources, as steel coils can be easily adapted and customized to meet specific project requirements. This versatility also enables the use of steel in sustainable building designs, such as energy-efficient structures or green buildings that incorporate renewable energy systems. In conclusion, the environmental benefits of using steel coils include their recyclability, durability, resistance to corrosion, and versatility. By choosing steel coils for various applications, we can contribute to resource conservation, reduced carbon emissions, and a more sustainable future.

- Q: pros and cons of stainless steel and carbon steel swords

- Well generally Stainless steel blades are machine made and are of a display quality.. so expect looks, but don't expect quality or functionality from one. From carbon steel, I'd say you'd be looking at swords for practitioners of a sword art, reenactment, and collector quality blades. Stainless Steel Pros: Good for short blades like kitchen knives, cheap, won't easily rust or corrode. Cons: Long blades like swords become increasingly brittle and can snap with light use, most lack actual tangs(part of the blade that keeps the blade in the handle.) and are just welded onto a wire that[if broken} will send the blade out like a missile when swung, these are cheap display quality only. Carbon Steel Pros: Are usually much stronger and of a higher quality than their stainless counterparts, are often handmade by professional sword-smiths, no two blades are alike, fully functional work of art. Cons: Requires responsible care and maintenance, will corrode and rust easier, can be much more expensive.

- Q: How do steel coils contribute to the energy infrastructure sector?

- The energy infrastructure sector heavily relies on steel coils, which are essential for constructing and maintaining various energy-related structures and equipment. To begin, steel coils are extensively employed in manufacturing pipelines, the lifelines of the energy industry. These pipelines transport oil, natural gas, and other energy resources across long distances, guaranteeing a consistent supply to power plants and other energy facilities. The use of steel coils in producing seamless and welded pipes ensures high strength, durability, and resistance to corrosion, making them well-suited for handling the challenging conditions of energy transportation. Apart from pipelines, steel coils are also used in the production of storage tanks for oil, natural gas, and other fuels. These tanks play a crucial role in storing large quantities of energy resources, ensuring an uninterrupted supply even during periods of high demand. By utilizing steel coils to fabricate the tank shells, the necessary strength and structural integrity are achieved, enabling them to withstand the pressure and environmental factors associated with energy storage. Moreover, steel coils play a vital role in the construction of power plants and other energy infrastructure facilities. They are utilized in manufacturing structural components like beams, columns, and supports, which provide the foundation and stability required for the safe operation of these facilities. Additionally, steel coils contribute to the production of equipment such as turbines, generators, and transformers, which are essential for converting energy into usable forms and distributing it to end-users. Furthermore, steel coils are employed in the construction of transmission towers and electrical grids. These structures and networks are responsible for transmitting electricity from power plants to residential, commercial, and industrial consumers. By using steel coils to manufacture the towers and poles that support high-voltage transmission lines, their stability and reliability in transmitting electricity over long distances are ensured. In conclusion, steel coils are irreplaceable in the energy infrastructure sector, providing the necessary materials for constructing, maintaining, and operating pipelines, storage tanks, power plants, transmission towers, and electrical grids. Their strength, durability, and resistance to corrosion make them the ideal choice for withstanding the demanding conditions of the energy industry, thereby ensuring a reliable and efficient energy supply to meet the growing needs of society.

- Q: What are the common coil inspection techniques?

- Some common coil inspection techniques include visual inspection, magnetic particle inspection, eddy current testing, and ultrasonic testing.

- Q: Can steel coils be used in the production of construction machinery?

- Yes, steel coils can be used in the production of construction machinery. Steel coils are often used as raw materials for manufacturing various components of construction machinery, such as frames, supports, and structural parts. The strength, durability, and resistance to corrosion of steel make it an ideal material for construction machinery, ensuring the longevity and reliability of the equipment.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings for various purposes such as structural support, reinforcement, and as raw materials for manufacturing components like beams, columns, and steel plates. The coils are often transformed into different shapes and sizes through processes like cutting, bending, and welding to meet specific construction requirements. They provide strength, durability, and stability to building structures, making them a crucial element in the construction industry.

- Q: What is the lifespan of a steel coil?

- The lifespan of a steel coil can vary depending on various factors such as the quality of the steel, its usage and maintenance. However, on average, a well-maintained steel coil can last anywhere from 10 to 30 years.

- Q: How are steel coils used in the production of electrical resistors?

- Steel coils are used in the production of electrical resistors as they provide a conductive material that can withstand high temperatures. The steel coil is wound into a spiral shape to increase the length of the wire, which in turn increases the resistance. This allows the resistor to regulate the flow of electric current in a circuit, providing the desired level of resistance.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price color is green

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords