Pre-Painted Galvanized/Aluzinc Steel Coil With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

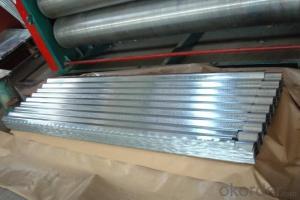

Pre-Painted Galvanized/Aluzinc Steel Coil With High Quality

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- Modulus Of Rigidity Of Steel

- Q: Are steel coils affected by magnetic fields?

- Yes, steel coils can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized or attracted to magnets. When a magnetic field is applied to a steel coil, it can induce a magnetic field within the coil, causing the coil to become magnetized. This can have several effects depending on the strength and duration of the magnetic field. If the magnetic field is strong and the coil is exposed to it for a significant amount of time, it can cause the steel coil to retain some magnetism even after the magnetic field is removed. This can be problematic in certain applications where a non-magnetic material is required, as the magnetized steel coil may attract or interfere with other nearby objects. On the other hand, if the magnetic field is rapidly changing or fluctuating, it can induce electrical currents within the steel coil through electromagnetic induction. These induced currents, known as eddy currents, can generate heat within the coil, leading to energy losses and potential damage to the coil. Therefore, it is important to consider the effects of magnetic fields on steel coils in various applications. Protective measures such as shielding or demagnetizing processes may be necessary to minimize the impact of magnetic fields on steel coils when required.

- Q: How are steel coils used in the manufacturing of household goods?

- Household goods rely on steel coils for their manufacturing, utilizing them in various ways. One notable application is in the creation of appliances like refrigerators, washing machines, and ovens. These coils are skillfully molded and formed into different parts and components, fortifying the final product with durability and robustness. Moreover, furniture manufacturing frequently incorporates steel coils, specifically in constructing metal frames for chairs, tables, and bed frames. The coils can be bent, welded, or molded to desired specifications, providing a solid and dependable foundation for these essential household items. Additionally, steel coils find utility in the production of kitchen utensils and cookware. These coils can be expertly stamped or pressed into diverse shapes, including pots, pans, and cutlery. Consequently, this process generates long-lasting and heat-resistant products that are indispensable for everyday cooking and food preparation. In essence, steel coils assume a critical role in the manufacturing of household goods, imparting strength, durability, and adaptability to a wide array of products.

- Q: i got the belly button ring from icing and its surgical steel are they the same things?

- yes they are same kind of steel

- Q: I work with stainless steel a lot and I know it's rust resistant but it's definitly not STAIN resistant. You might be able to remove some stains easier from it than you can from some other surfaces but when it does stain, its hard as heck to clean it. It takes forever to scrub stains off my stainless steel pans so maybe it should just be called rustless steel?

- This okorder /

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes include scratches, pits, roll marks, stains, and unevenness. These defects can be caused by various factors such as improper handling, processing issues, or equipment malfunction. These surface defects affect the aesthetics and quality of the steel coil, making it unsuitable for certain applications or requiring additional processing to rectify the defects.

- Q: How are steel coils used in the production of steel latches?

- Steel coils are used in the production of steel latches as they serve as the raw material for manufacturing these components. The coils are processed through various manufacturing steps, such as cutting, stamping, and forming, to shape them into the desired latch design. These transformed steel coils are then further treated with coatings or finishes to enhance their durability and corrosion resistance. Ultimately, steel coils play a crucial role in providing the base material necessary for creating sturdy and functional steel latches.

- Q: I want to hear from those who own a scandium revolver. I know that scandium makes for a much lighter gun than steel, but how do they hold up durability-wise? Is their lifespan shorter than a comparable steel revolver?

- This Site Might Help You. RE: Are scandium revolvers as durable as steel? I want to hear from those who own a scandium revolver. I know that scandium makes for a much lighter gun than steel, but how do they hold up durability-wise? Is their lifespan shorter than a comparable steel revolver?

- Q: How are steel coils used in the production of electrical switches?

- Steel coils are used in the production of electrical switches as the core component of electromagnetic relays. When an electric current passes through the coil, it generates a magnetic field which attracts or repels a metal armature, thus opening or closing the electrical circuit. This mechanism allows electrical switches to control the flow of electricity in various applications.

- Q: How do steel coils contribute to the automotive aftermarket?

- Steel coils contribute to the automotive aftermarket by serving as a crucial raw material for manufacturing various components used in vehicles. These coils are responsible for providing strength, durability, and structural integrity to parts like body panels, chassis components, suspension systems, and exhaust systems. Additionally, steel coils are also used in the production of aftermarket accessories such as bumpers, grilles, and custom body kits. Their availability and versatility make steel coils an essential resource for the automotive industry, enabling the production of high-quality aftermarket products that enhance the performance and aesthetics of vehicles.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords