Pre-Painted Galvanized/Aluzinc Steel Coil with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

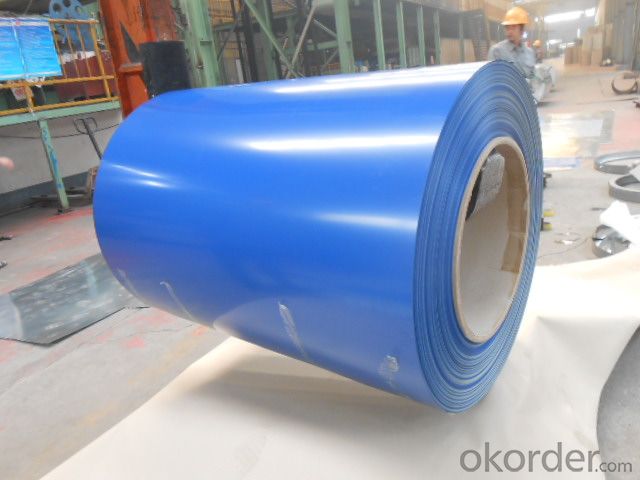

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

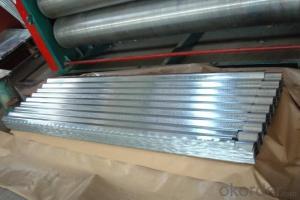

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

- Q: How are steel coils used in the manufacturing of industrial boilers?

- Steel coils are used in the manufacturing of industrial boilers as they provide a strong and durable material for constructing the boiler's shell and tubes. The coils are shaped and welded together to form the boiler's structure, ensuring a sturdy and reliable construction. Additionally, the steel coils are often coated or treated to resist corrosion and withstand high temperature and pressure conditions, making them suitable for the demanding environment of industrial boiler operations.

- Q: What temp does fire have to be to melt steel?

- There are different types of steel. Melting point of steel depends upon its contents. Generally the melting point of stell is above 1500 c.

- Q: Can steel coils be coated with decorative designs?

- Yes, steel coils can be coated with decorative designs. This can be achieved through various methods such as painting, printing, or applying specialized coatings. The decorative designs can enhance the aesthetic appeal of the steel coils and be customized according to specific requirements.

- Q: My company want to welding stainless steel, do not know to use what welding machine?

- There are many ways in welding stainless steel, such as coating manual welding,argon arc welding, pulsed argon arc welding, MIG, pulsed MIG, double pulsed MIG. Different welding ways own their merits and faults and adaptive working conditions. It is recommended to choose pulsed MIG, its molding very good and efficiency high, so it is mainstream application for stainless steel welding. Now many digital welding machines can supply these welding methods at the same time. And their welding effects is far better than traditional machines. Among them, FRONIUS’s TPS series and Nebula series are representitive products.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- You can use steel but alloyed with a big percent of Mn and Cr. Titanium is very good but unfortunately it is expensive. On engines and Turbine blades it is indicate to use High Alloy metals that are resistant to fluage.

- Q: How do steel coils contribute to the manufacturing of household appliances?

- Steel coils contribute to the manufacturing of household appliances by providing a durable and versatile material for various components. These coils are used to create the outer casings, frames, and structural parts of appliances like refrigerators, washing machines, and dishwashers. The strength and flexibility of steel coils ensure the longevity and stability of these appliances, while also enabling manufacturers to create sleek and attractive designs.

- Q: What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils utilized in the electrical equipment industry may differ based on the particular application and requirements of the equipment being produced. However, there are certain dimensions that are commonly employed in this industry. Typically, the width of steel coils employed in the manufacturing of electrical equipment ranges from 0.5 inches to 72 inches (1.27 cm to 182.88 cm). The thickness of these coils can vary from extremely thin, measuring 0.005 inches (0.0127 cm), to considerably thick, measuring 0.25 inches (0.635 cm). The length of steel coils employed in the electrical equipment industry can also vary, but it is often determined by the production process and the specific equipment being manufactured. Coils can range in length from a few feet to several hundred feet. Moreover, the weight of steel coils can differ based on their dimensions and the type of steel being utilized. For example, a common weight range for steel coils employed in the electrical equipment industry falls between 5,000 pounds (2,268 kg) and 50,000 pounds (22,680 kg). It should be noted that these dimensions are not fixed and can vary depending on the specific requirements of the electrical equipment industry. Manufacturers may have their own distinct specifications and requirements for the steel coils they utilize in their products.

- Q: How are steel coils used in the manufacturing of electrical appliances?

- Steel coils are used in the manufacturing of electrical appliances primarily for their magnetic properties. These coils are wound around a core to create electromagnets, which are essential components in various appliances like transformers, motors, generators, and solenoids. The magnetic field generated by the steel coils allows for the efficient conversion of electrical energy into mechanical energy or vice versa, enabling the proper functioning of these appliances.

- Q: How are steel coils used in the production of electronic devices?

- Steel coils find extensive application in the production of electronic devices, serving various purposes. One prominent utilization lies in the manufacturing of transformers and inductors, which constitute essential components in numerous electronic devices. These components comprise a coil of wire wound around a core, with steel coils often serving as the core material due to their magnetic properties. The magnetic properties of steel contribute to amplifying the magnetic fields generated by the coils, facilitating effective energy transfer and voltage regulation. Steel's magnetic attributes, such as high permeability and low hysteresis loss, make it an ideal material for such applications. Furthermore, steel coils are also integral to the production of printed circuit boards (PCBs). PCBs, acting as the backbone of most electronic devices, consist of a flat, non-conductive board like fiberglass, adorned with a thin layer of copper traces etched onto it. These copper traces establish the electrical connections between different components on the board. Steel coils play a role in the PCB fabrication process, specifically in the creation of stencils. These stencils are employed to apply solder paste onto the board before component placement. Laser-cut steel coils give rise to accurate and consistent stencil patterns, ensuring precise solder paste application. To summarize, steel coils fulfill a crucial function in the production of electronic devices. They are employed in the manufacturing of transformers and inductors, enhancing energy transfer and voltage regulation through their magnetic properties. Additionally, steel coils contribute to the fabrication of PCBs by creating stencils for solder paste application. Overall, the use of steel coils guarantees the efficient and dependable operation of electronic devices.

- Q: What are the different methods of coil packaging for steel coils?

- Steel coils can be packaged using various methods, each with its own advantages and suitability for specific applications. Some commonly used methods include: 1. Strapping: Steel or plastic strapping is used to secure the coil and prevent unwinding or shifting during transportation. Strapping can be done manually or with strapping machines, providing a reliable and cost-effective packaging solution. 2. Stretch wrapping: This method involves tightly wrapping the coil with a stretch film. The film is stretched and wrapped around the coil, offering protection against dust, moisture, and damage. Stretch wrapping is suitable for lightweight coils and provides good visibility of the product. 3. Steel banding: This robust and heavy-duty method uses steel bands to secure the coil. It ensures high strength and durability, keeping the coil intact during transportation or storage. 4. Edge protectors: To safeguard the edges of the coil, edge protectors made of cardboard or plastic are used in combination with other packaging methods. These protectors provide additional support to prevent edge damage. 5. Wooden crates: For heavy or fragile steel coils, wooden crates are often used to provide maximum protection. The coils are placed inside the crate and secured with strapping or steel banding. Wooden crates offer excellent strength, stability, and can be customized to fit specific coil dimensions. 6. Paper interleaving: This method involves inserting layers of paper or cardboard between individual wraps of the coil to prevent scratching or marking. Paper interleaving is commonly used when stacking coils or when protecting a high surface finish. 7. Automated packaging systems: In larger-scale operations, automated packaging systems can be used. These systems are designed to handle and package coils using various methods such as strapping, stretch wrapping, or steel banding. They ensure increased efficiency, productivity, and consistent and secure packaging. The choice of coil packaging method depends on factors including coil size and weight, transportation requirements, required level of protection, and cost considerations. It is crucial to select the appropriate packaging method to ensure the safe delivery of steel coils to their destination.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords