Vinyl Coated Aluminum Coil for Pre-painted Advertisement Boards and Traffic Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Pre-painted Advertisement Boards and Traf Aluminum Coil

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

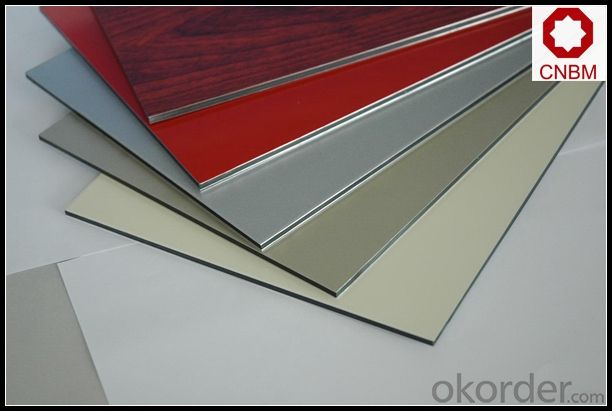

2. Application of Pre-painted Advertisement Boards and Traf Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Pre-painted Advertisement Boards and Traf Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

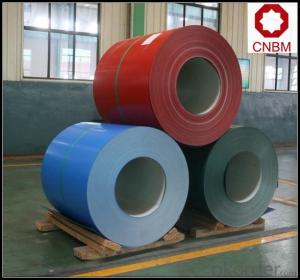

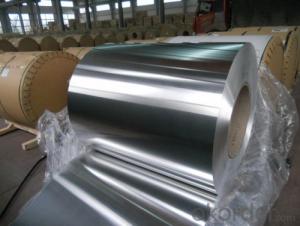

5. Image of Pre-painted Advertisement Boards and Traf Aluminum Coil

6. Package and shipping of Pre-painted Advertisement Boards and Traf Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of coil-brushed aluminum coils?

- Coil-brushed aluminum coils have a range of potential applications due to their unique properties. They can be used in interior design, architecture, automotive industry, appliances, electronics, and even in the manufacturing of furniture and decorative items. The brushed texture on the surface of the aluminum adds an aesthetic appeal and can be employed for creating modern, sleek, and sophisticated designs. Additionally, the durability and corrosion resistance of aluminum make it suitable for outdoor applications such as signage and cladding.

- Q: Can aluminum coils be painted?

- Yes, aluminum coils can be painted. Painting aluminum coils can provide an added layer of protection against corrosion and enhance their aesthetic appearance. However, it is important to properly prepare the surface before painting to ensure good adhesion and durability. This typically involves cleaning the coils thoroughly, removing any existing paint or coatings, and applying a primer specifically designed for use on aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. It is recommended to use a high-quality paint specifically formulated for use on metal surfaces to ensure long-lasting results. Additionally, it is important to follow the manufacturer's instructions and consider any environmental factors that may affect the painting process, such as temperature and humidity.

- Q: Can aluminum coils be utilized as a material for crafting jewelry?

- <p>Yes, aluminum coils can be used for making jewelry. Aluminum is a lightweight, durable, and affordable metal that is often used in costume jewelry and for decorative purposes. It can be easily shaped, bent, and manipulated into various forms, making it suitable for creating intricate designs. However, it's important to note that aluminum is a softer metal and may not be as durable as other metals like stainless steel or silver, so it may not be ideal for pieces that will be worn daily or subjected to significant wear and tear.</p>

- Q: Can aluminum coils be used in the production of aluminum garage doors?

- Yes, aluminum coils can be used in the production of aluminum garage doors. Aluminum is a popular material choice for garage doors as it is lightweight, durable, and resistant to corrosion. Aluminum coils are typically used to create the panels and frames of the garage doors. These coils can be easily formed and shaped into the desired design for the garage door. Additionally, aluminum coils can be powder coated or painted to provide a finished look and enhance the aesthetics of the garage door. Overall, aluminum coils are a versatile and practical choice for the production of aluminum garage doors.

- Q: Can aluminum coils be used in heat sinks?

- Yes, aluminum coils can be used in heat sinks. Aluminum is a popular choice for heat sinks due to its excellent thermal conductivity. Heat sinks are designed to dissipate heat from electronic components and other devices to prevent overheating. The use of aluminum coils in heat sinks allows for increased surface area, which enhances heat dissipation. The coils can be shaped and arranged in various configurations to optimize cooling efficiency. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a practical choice for heat sink applications.

- Q: Can aluminum coils be recycled multiple times?

- Aluminum coils possess the remarkable ability to be recycled numerous times. This is due to the fact that aluminum is an exceptionally recyclable substance, and its quality remains unaltered throughout the recycling process. As a result, aluminum coils can be melted and reshaped into fresh coils on multiple occasions, without experiencing any deterioration in their performance or characteristics. The act of recycling aluminum not only aids in the preservation of natural resources, but it also conserves a significant amount of energy compared to the production of new aluminum using raw materials. Consequently, opting for aluminum coils is a sustainable and eco-friendly decision, as they can be recycled multiple times.

- Q: Can aluminum coils be used in high-altitude environments?

- Indeed, the utilization of aluminum coils is feasible in high-altitude settings. Thanks to its lightweight and resistance to corrosion, aluminum is a fitting material for various purposes, including in high-altitude scenarios. Aluminum coils are often employed in air conditioning systems, heat exchangers, and refrigeration units, all of which can operate efficiently at high altitudes. The high strength-to-weight ratio of aluminum enables it to endure the harsh conditions encountered at high altitudes, encompassing low temperatures, strong winds, and low atmospheric pressure. Moreover, aluminum is non-magnetic, providing an advantage in specific high-altitude applications like aerospace and satellite technologies. Additionally, aluminum exhibits exceptional thermal conductivity, facilitating efficient heat transfer and rendering it perfect for deployment in cooling systems functioning in high-altitude environments. Its resistance to corrosion also ensures durability and the ability to withstand the impact of moisture, which can be prevalent in such settings. All in all, owing to their lightweight nature, resistance to corrosion, thermal conductivity, and strength, aluminum coils serve as a dependable and appropriate choice for utilization in high-altitude environments.

- Q: Can aluminum coils be anodized for enhanced durability?

- Indeed, it is possible to anodize aluminum coils in order to enhance their durability. Anodization involves the creation of a layer of aluminum oxide on the surface of the aluminum, resulting in increased resistance to corrosion, wear, and scratches. This layer also offers added protection against UV rays and harsh environmental conditions. By subjecting aluminum coils to anodization, they become more resilient and capable of enduring extended use in a variety of industries, including construction, automotive, and electronics. Moreover, anodized aluminum coils can be further enhanced with additional coatings or finishes to improve their appearance and provide additional protection. Overall, anodizing aluminum coils is a widely employed and efficacious technique for boosting their durability and extending their lifespan.

- Q: Will aluminum foil go off in a metal detector

- aluminum is undectable if you wrap your eay pass in it it wont register. i tried it. and a feriday cage wraped in tinfoil will block all signals to everything

- Q: Is it safe to use aluminum coil for storing food?

- <p>Aluminum coil can be used for food storage, but with certain considerations. Aluminum is a good conductor of heat and is often used in cookware, but for long-term food storage, it's not ideal. It's important to ensure that the aluminum is coated or lined with a non-reactive material to prevent direct contact with food, as aluminum can leach into food and may have health implications. Additionally, aluminum is not recommended for acidic foods as it can react with them. For best food storage practices, consider using materials specifically designed for food contact, such as glass or food-grade plastic containers.</p>

Send your message to us

Vinyl Coated Aluminum Coil for Pre-painted Advertisement Boards and Traffic Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords