Practical HZS90 low cost concrete batching plant small concrete batching plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

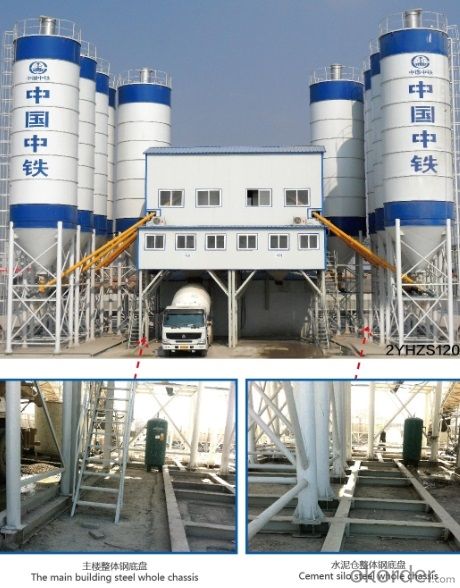

HZS90 concrete batching plant

Quick Details

Condition: New

Power Type: Electric

Place of Origin: Shandong, China (Mainland)

Brand Name: Xinxing

Model Number: HZS(N)

Power(W): 145kw

Certification: CE & ISO9001

Warranty: 12 months

After-sales Service Provided: Overseas service center available

Capacity: 90 m3/h

Mixing Time: 60s

Max Aggregate Size: 60/80 mm

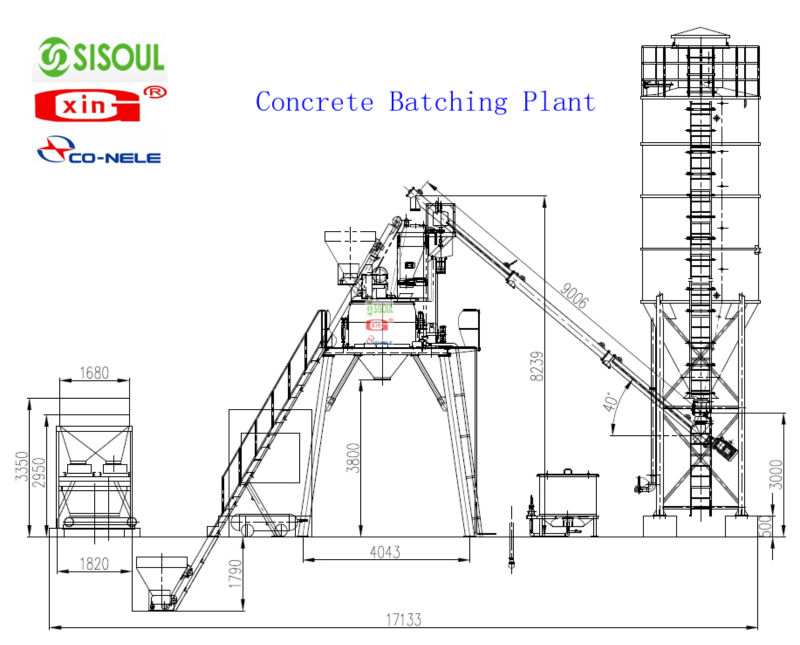

Discharging Height: 3800 mm

Total Power: 110kw

Total Weight: 60t

Total Dimensions: 38500x12000x19400 mm

Main characteristics

1) Excellent mixing performance

2) Highest reliable performance

3) Unique no-sticky shaft technology

4) Accurate measurement accuracy

5) Perfect industrial design

6) Convenient transportation and installation

7) Simple operating performance

8) Good maintenance performance

9) Excellent environmental protection performance

10) TV monitoring system

Introduction

♦HZS series concrete mixing/bantching plant description

♦HZS Series mixing plant is special construction concrete equipment, developed and designed independently on the basic of CO-NELE CTS series mixer according to the advantage of the same type at home and abroad.

♦It is applied for airfield runway, wharf, road, and bridge and so on and it can also be used for the large and emergency repair construction operation.

♦It can be installed quickly on site.

♦This mixing plant integrate mixer, batching system, feeding system, and weighing system, cement silo, screw conveyor and all the necessary equipment into together.

And also has the characteristic of mixing well, high productivity, highly

automated, high flexibility, convenient operation, and good stability.

| em | Type | ||||||

| HZS60 | HZN60 | HZS90 | HZN90 | HZS120 | HZS180(150) | HZS240(200) | |

| Theoretical Productivity(m³/h) | 60 | 60 | 90 | 90 | 120 | 180(150) | 240(200) |

| Mixer | JS1000 | MP1000 | JS1500 | MP1500 | JS2000 | JS3000 | JS4000 |

| Batching System | PLD1600 | PLD1800 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Discharge height(mm) | 4100 | 4840 | 4100 | 4100 | 4100 | 4100 | 4100 |

| The Max. Diameter of the Aggregates(mm) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) |

| Automatic Cycle Period(s) | 60 | 60 | 60 | 60 | 60 | 60(72) | 60(72) |

| Weighing Precision of Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Weighing Precision of Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Additive | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Power(KW) | 106 | 114 | 145 | 145 | 175 | 215 | 295 |

- Q: Is the concrete mixer and mortar mixer a machine

- Principle, working condition and so on but the mortar mixer design than concrete mixer So you can use concrete mixer mixing mortar, but unfavorable use mortar mixer mixing concrete

- Q: How is the concrete mixer cleaned

- I don't know which type of blender you're talking about. The self-falling mixer is the roller mixer. Rinse directly with water. The strong mode is also the JS mixer water rinse to notice whether the shaft end of the shaft is clean, and be careful not to use the side shovel to break down otherwise there will be a sealing problem

- Q: How the concrete mixer works

- 1) self-falling blender The inner wall of a self-falling mixer has curved blades. When the cylinder is rotated around the horizontal axis, the blade constantly elevating the material to a certain height, and then the free fall, blending with each other. (2) a strong mixer A strong mixer is mainly based on the shear mechanism. In a blender, there are blades that rotate in a stirring shaft. (3) the selection and application of mixers 1) type selection Concrete mixer should according to the project specific conditions (such as size, length of time limit for a project of quantities) and the requirements on the performance of concrete to be right choice. 2) the production capacity of the mixer is calculated The productivity of the blender is calculated in the following form: Q = 3.6, VK/t1t2t3 (m3 / h) Type t1, t2, t3 - for loading, stirring, discharging time (S); V -- the capacity of the blender; K - the utilization factor of each working time.

- Q: How many cubic meters of concrete is mixed with concrete mixer?

- The 1000 type 1 square 2000 type 2 square 3000 3 square

- Q: Common type of concrete mixer

- The type of concrete mixer used, the method of work: strong mode; Drum. The size of the mix is divided into: 250 (0.25 cubic); 350 (0.35 cubic meters); 500 (0.5 cubic); 750 (0.75 cubic per square).

- Q: How much is the blender machine stirring

- The JZC350 concrete mixer is a two-cone-shaped machine that inverts the flow mixer, which can be mixed with the plastic and semi-dry concrete of 60 mm. Stirring when the mixer is turning, and automatically when reversing. Each pot can be mixed with concrete 0.35 cubic meters. Native novel structure, advanced performance, high productivity, mixing of good quality, compact structure, low energy consumption, the advantages of convenient operation, applicable to the general construction sites, road, bridge engineering and small concrete precast construction situations such as a file. The output capacity is 350 litres The incoming capacity is 560 liters 4, productivity 10 ~ 14 m 3 / h The work cycle is 30 to 40 times per hour 6, form a complete set of power

- Q: Operation procedure of concrete mixer

- Safety procedure of concrete mixer A blender must be placed in a solid place, secured with a bracket or a leg holder, and no tires should be replaced. Before starting the mixer, the clutch, brake, wire rope and so on should be checked, and no foreign material in the roller. When the hopper is hoisted, no one shall pass or stay in the hopper, and the hopper shall be fixed after the work is completed. When running, it is strictly forbidden to put the tool into the roller. It is strictly forbidden to leave the work station without any evidence of operation or operation. When repairing, should fix the hopper, cut off the power supply. After the work is finished, should clean the fuselage concrete, do the lubrication to maintain, cut off the power to lock the door.

- Q: For example, what is the more detailed and better td-50 td-80 td-60

- Concrete mixer points generally mixer and forced mixer, currently used in engineering is forced, the difference is that the former is the shell in turn, the latter is in inside agitation. The most commonly used parts of a strong mixer are: hoisting bucket wheel, mixing arm, blade, hopper limiter, liner. Normally the mixing arm, blade, and lining plate for the vulnerable parts, should be replaced in time during construction.

- Q: What is the type of concrete mixer?

- Concrete mixer type mainly has: JZC250, JZC350, JZC500, JZM350, JZM500, JZM750, JDC350, JDC500, JDY350, JDY500 etc., including JZM is friction type drum mixer, JDY/JDC for single horizontal-axis forced concrete mixer, JZC fell for type concrete mixer drum.

- Q: 250 litres of the blender once made concrete

- 250-litre agitator is measured at a time of 0.25 m3, which is about 80% of the amount in real time, avoiding mixing and mixing

Send your message to us

Practical HZS90 low cost concrete batching plant small concrete batching plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches