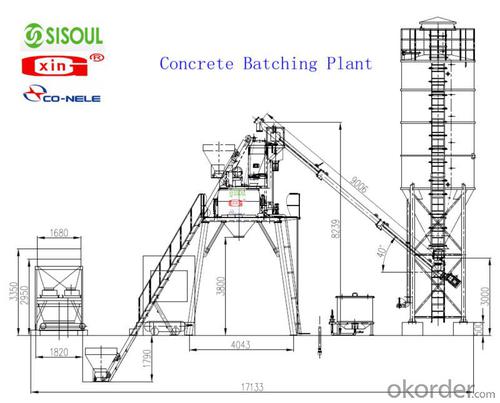

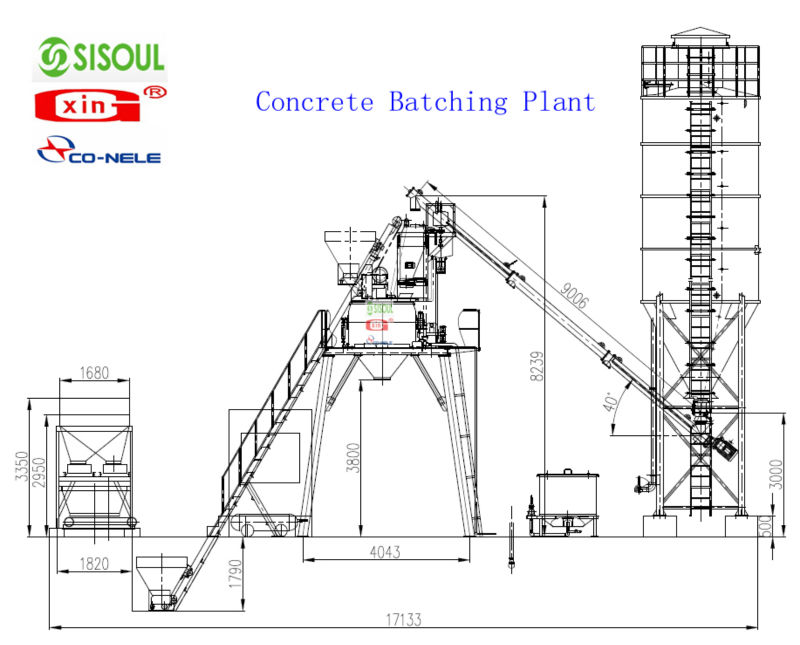

HZS90 concrete batching plant Mixing Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

HZS90 concrete batching plant

Quick Details

Condition: New

Power Type: Electric

Place of Origin: Shandong, China (Mainland)

Brand Name: Xinxing

Model Number: HZS(N)

Power(W): 145kw

Certification: CE & ISO9001

Warranty: 12 months

After-sales Service Provided: Overseas service center available

Capacity: 90 m3/h

Mixing Time: 60s

Max Aggregate Size: 60/80 mm

Discharging Height: 3800 mm

Total Power: 110kw

Total Weight: 60t

Total Dimensions: 38500x12000x19400 mm

Main characteristics

1) Excellent mixing performance

2) Highest reliable performance

3) Unique no-sticky shaft technology

4) Accurate measurement accuracy

5) Perfect industrial design

6) Convenient transportation and installation

7) Simple operating performance

8) Good maintenance performance

9) Excellent environmental protection performance

10) TV monitoring system

Introduction

♦HZS series concrete mixing/bantching plant description

♦HZS Series mixing plant is special construction concrete equipment, developed and designed independently on the basic of CO-NELE CTS series mixer according to the advantage of the same type at home and abroad.

♦It is applied for airfield runway, wharf, road, and bridge and so on and it can also be used for the large and emergency repair construction operation.

♦It can be installed quickly on site.

♦This mixing plant integrate mixer, batching system, feeding system, and weighing system, cement silo, screw conveyor and all the necessary equipment into together.

And also has the characteristic of mixing well, high productivity, highly

automated, high flexibility, convenient operation, and good stability.

| em | Type | ||||||

| HZS60 | HZN60 | HZS90 | HZN90 | HZS120 | HZS180(150) | HZS240(200) | |

| Theoretical Productivity(m³/h) | 60 | 60 | 90 | 90 | 120 | 180(150) | 240(200) |

| Mixer | JS1000 | MP1000 | JS1500 | MP1500 | JS2000 | JS3000 | JS4000 |

| Batching System | PLD1600 | PLD1800 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Discharge height(mm) | 4100 | 4840 | 4100 | 4100 | 4100 | 4100 | 4100 |

| The Max. Diameter of the Aggregates(mm) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) |

| Automatic Cycle Period(s) | 60 | 60 | 60 | 60 | 60 | 60(72) | 60(72) |

| Weighing Precision of Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Weighing Precision of Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Additive | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Power(KW) | 106 | 114 | 145 | 145 | 175 | 215 | 295 |

- Q: What is the concrete of the mixing station?

- What else can you do to sell concrete What is the station

- Q: Cement warehouse introduction, storage reserves?

- This one has a lot of small, see how to configure, usually at 200 tons above each warehouse

- Q: How much concrete is produced per hour by HZS180 concrete mixer?

- HZS180 concrete production line equipment production line equipment per hour theory produces 180 cubic concrete. It depends on the equipment situation. Henan zheng a heavy industrial concrete mixing plant equipment factory

- Q: How much water does a concrete mixer use every day?

- Dosage, depending on your project and mixing station construction factory cleaning every day, because now the country's love the strict monitoring of environmental protection, to maintain clean our factory, is a lot of water to clean the work area. So the client had better prepare the pool to ensure the normal operation of the project.

- Q: How to choose a good concrete mixer station?

- For simple concrete mixup stations, the overall cost of equipment is much cheaper, because the configuration is different and a lot of configuration is eliminated. But cement weighing cannot save configuration independent water weighing measurement more accurate to efficient, do not use water weighing system can also be mixing concrete, but there is a big hidden trouble. The water weighing system is not suitable for individual water weighing system, and it can reduce the investment of a simple mixing station by about 7, 000 yuan. And shortcomings is not water in the mixing drum of the weighing system and water, time node device can be used to set the water within a certain time interval to churn, but increased water and forced concrete mixer mixing time, still can cause concrete model is not stable. Therefore, although do not use water weighing system can save investment, but will increase the mixing time of concrete and affect the stability of the concrete, so the customer can choose according to oneself circumstance.

- Q: What are the facilities of the concrete mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system

- Q: What is the difference between a concrete mixer and a concrete mixer

- The bone material of the mixing tower is on the top, and the aggregate is measured directly into the mixer. The concrete bin of the commercial concrete station is below, and the bone material is measured and then transported into the mixer after being transported by the inclined belt (which also has some use of the elevator). In a popular way, it is called the building, which is called the second ascent. The steel structure will be larger and the diagonal belt will be relatively longer because of the bone material in the mixing building. But in productivity, the churn is about a fifth higher than the commercial concrete station. In operation, because the inclined belt of the commercial concrete station starts frequently, the energy consumption and the failure rate will increase, and the energy consumption of the mixing building is lower than the failure rate. In the end, because the production capacity of the concrete station is small, the structure is easily disassembled and can be made into a container transfer site, which is suitable for the construction site. The mixing tower is large and high in productivity, and can only be used as a fixed mixer, suitable for the supply of large water projects or large quantities of goods. So customers in the difference between commercial concrete, concrete stand and commodity concrete mixing floor, from aggregate (material), the production efficiency and so on, to choose and buy the right equipment.

- Q: Concrete mixstations belong to no special equipment

- The boiler is a special equipment in the stirring station.

- Q: The mixing time of the concrete mixer is in which standard

- The quality control standard gb50164-2011 should not be produced for 40 seconds in the winter of 30 seconds

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Yes, the general commodity concrete mixing station will write like this, the benefit of writing is simple and convenient, because the concrete three words are really too complicated! Zhengzhou zhengchen industrial production commodity concrete mixing station equipment.

Send your message to us

HZS90 concrete batching plant Mixing Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords