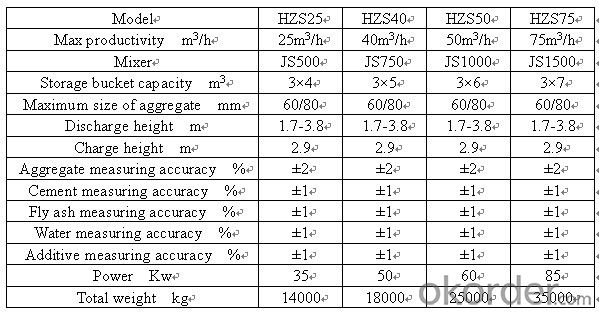

concrete batching plant HZS40

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This concrete mixing station has higher intelligent automation function, which is a small and medium sized forced-type mixing station, featuring compact structure, flexible layout, low investment, convenient transport and disassembly, which are favored by users.

The station is composed of material supply, metering system, mixing system, electrical control system, pneumatic control system, etc., which can mix various types of concrete, and is especially suitable for mixing dry and hard concrete, which is applicable for at least medium-sized construction engineering, water and electricity, roads, ports, docks, bridges and other projects as well as larger and medium-sized manufacturing factories and concrete production plants.

The station can store three different types of aggregates. Charging is realized via loaders. Three cement silos and the corresponding spiral conveyor are equipped. Aggregates, additives, water and cement are all measured with electronic scales. The main machine of the mixers is of twin-shaft type, featuring good mixing quality and high production efficiency. The station can be run either automatically under computer control or manually. The computer controlled system has dosing storage, drop automatic compensation, exception case alerts and other functions. The control parameters can be modified randomly and do not loss in the case of power failure. It is also equipped with a printer. (Cement silo and spiral conveyor are ordered by the user specially). In addition, the control system employs bilingual control, which can facilitate the operation of operators.

- Q: The main components of a mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system.

- Q: What is the concrete of the mixing station?

- Concrete mixing stations are made of concrete, which is made of concrete for various construction sites, including commercial housing, concrete floor, industrial workshop and so on.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- Many manufacturers will say that the HZS90 station is the one that makes 90 square concrete. In fact, the HZS90 station is supposed to produce 90 square concrete when it is in theory, and it is actually not up to 75 square

- Q: What is the concept of on-site concrete mixer station

- Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Action: concrete mixing plant is used to concentrate the mixing of concrete, also called concrete precast. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions. Basic introduction: concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities.

- Q: How much concrete is produced per hour by HZS180 concrete mixer?

- Depending on the different areas of the site, the requirement is between 10 and 300, 000, which requires a high level of testing equipment. The cost is relatively higher. The best way is to find a few different test equipment suppliers, according to different manufacturers, equipment, and make a simple quote analysis

- Q: How to choose a good concrete mixer station?

- The concrete mixing station of choose and buy should focus on quality and quantity. Some users choose and buy when the concrete mixing station, don't know how should choose the equipment, now there are goods on the market of concrete mixing station, concrete mixing station, concrete mixing station. Users should choose different devices and different type of concrete mixing stations according to their own situation.

- Q: What constitutes the js750 concrete mixing station

- The concrete mixing station consists of the mixing system, the aggregate supply system, the measuring system, the control system and the external supporting equipment. The main purpose of the mixing station is to mix concrete, also called concrete mixing station. HZS series products adopt international popular cement concrete mixing station quickly assembled module type structure, high-performance imported agitator, double machine double control way of computer control, prevent noise, prevent dust pollution, environmental design, is the new generation of cement concrete mixing equipment, applicable to urban commodity ready-mixed concrete, road and bridge, water conservancy, airports, ports and other large infrastructure construction project and concrete demand for large sites.

- Q: What is the special work of the concrete mixing station

- The ratio of the concrete particles to the surface area, the shape of particles, the density of the particles and the grading of the particles, etc., are very important to the liquidity of the slurry. Smaller than surface area, the particle shape is closer to the ball, bigger, more filling and more liquid. By optimizing these factors, you can obtain the most appropriate liquidity. In order to design the concrete mix according to the engineering requirement, the characteristics of the aggregate material must be mastered first. The properties of aggregates are determined by factors such as microstructure, prior exposure and processing, and these factors influence the properties of fresh and hardened concrete. The effect of aggregate properties on concrete performance should be considered, and the quality of concrete mixing equipment should be considered. Before installation, check the appearance quality of the equipment again, the platform bolts are not loose, the welding seam is not cracked, the oil leak, the water, the ash (the lump), etc. Clean the assembly of the whole machine and re-spray paint, rust and renovate. Prepare the all kinds of bolts, welding wire, iron plate, etc., to prepare tools and protective equipment, the use of more tools for several sets of parts can use pneumatic wrench, and provide timely acetylene cutting, electric welding equipment; Plan the entry time of the crane.

- Q: What chemical materials are used in the concrete mixing station?

- Do you mean admixtures? You want to make sure that you have a function, what purpose do you want to be able to make clear, usually with a buffer, a dilatant, and a densifier, and so on

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- That depends on how many square measures you do in a day, and you typically do 1,000 concrete words 80 to 90 t

Send your message to us

concrete batching plant HZS40

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords