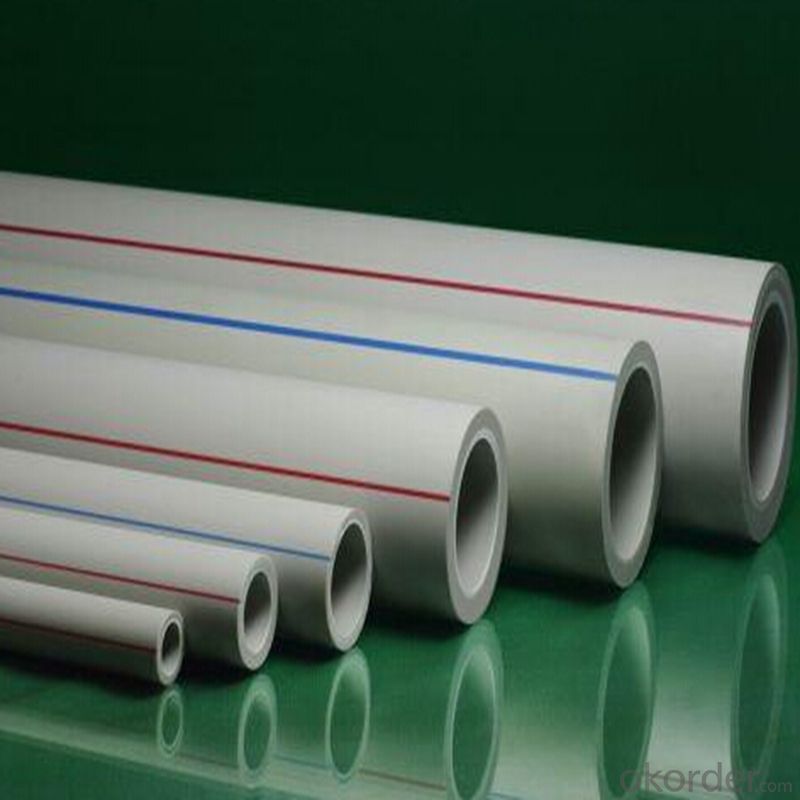

Plastic Tubes - PPR Pipes and Fittings for Industrial Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R(polypropylene random)pipes are adopted thermal welding technique during the project of hot / cold water transmission. The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Product Applications

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioner

Product Advantages

1. Sanitization & Non-poison: This product is green building material which is able to use for pure clean drinking water pipe system. No heavy metal additives would not be covered with dirt or contaminated by bacterium.

2. High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

3. Corrosion-Proof & Non-Fouling: Resist chemical matters or electron chemical corrosion. Able to avoid the pipe's fouling or blocking as well as the blemish, rust on basin and bath.

4. Heat Preservation & Energy-Saving: Excellent heat insulation features, minimal thermal conductivity which is only 0.5% of the conductivity of metal pipes.

5. Less Weight & High Strength: Its proportion is only 1/8th of metal pipe’s, with pressure-proof strength up to over 5MPa(50kg/sqcm),high tenacity and impact resistance.

Product Specification

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 10000pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

- Q: Those ices that come in a plastic tube.

- what flavor? cherry would have about 150 calories

- Q: Can the plastic water supply pipe be heated by electricity?

- Yes, but the temperature must be well controlled. The purpose of the water heater with the electric heater should be to prevent water from freezing!

- Q: How to mend a hole in a plastic pipe?

- A sheet of plastic, the thickness of which is equivalent to the wall of the basin. The material is then sanded with a sand wall and painted with 502 (501) glue. Press it quickly and press it for a few minutes.

- Q: Hello, I'm making my own skin hair care products and my question is, what store other than Micheals can I purchase plastic containers and tubes to put my product in? I'm not talking about food items either I'm talking about Jars to store shea cocoa butter in it. Also, I want to be able to provide my own wrapper? Like what can I do to make my own wrapper sticker ... basically advertising my own product line's name and whichever design I'd like on it?? Thanks in advance :)

- You can purchase standard plastic jars (10ml-500ml) from the UK specialist Manuplastics Ltd.

- Q: How do plastic tubes compare to stainless steel tubes in terms of weight?

- Plastic tubes typically weigh significantly less than stainless steel tubes.

- Q: How durable are plastic tubes?

- Plastic tubes are generally quite durable, as they are designed to withstand various conditions and impacts. However, their durability can vary depending on the type of plastic used and the intended purpose of the tube. Some plastic tubes are specifically engineered to be resistant to chemicals, UV rays, and extreme temperatures, making them highly durable in harsh environments. Additionally, the thickness and reinforcement of the tube can also affect its durability. Overall, plastic tubes are known for their strength and resilience, but it is important to choose the appropriate type and quality for specific applications.

- Q: I would like to give all the girls in my daughter's dance company single stemmed roses after they compete in an upcoming dance competition. I tried last year just keeping the flowers in the car in water but that didn't work very well. Plus it was a hassle getting them from the car since I had my daughter's costumes, make up, etc and other props. I would like to this year use those individual water tubes that usually come on single stemmed flowers but I'm not finding them. I am buying for about 30 girls so I need to keep this as affordable as possible. Any ideas on how to create a homemade version or buy them for cheap? I will call a florist but I'm anticipating them not selling to me because they would want me to buy the roses from them (I am just buying about 2 1/2 dozen and doing it myself.Thanks so much!

- You might try using plastic tubing and plugging the ends. Glass tubing is another way to go, more durable but also more expensive more work. Glass tubing can be cut to length then closed off on one end by heating in a flame until it pulls together. Large drinking straws could work as well, you could seal the bottoms with an iron by placing the straw between aluminum foil sheets.

- Q: Can plastic tubes be used for insulation in construction?

- Yes, plastic tubes can be used for insulation in construction. They are commonly used to insulate pipes and electrical wires to protect them from heat loss or gain and to prevent condensation. Plastic tubes provide a cost-effective and durable solution for insulation in various construction applications.

- Q: Hot melt construction technology of PPI plastic pipe

- To cut the pipe, the end face must be perpendicular to the axis of the pipe. The general use of the pipe or pipe cutting shear pipe cutting machine, if necessary, use a sharp saw, but after cutting the pipe section should remove burrs and burrs;

- Q: I'm building a science project with my little sister, and we quite frankly need some help. The plan is to make a little rollercoaster out of plastic tubing as the track. It's kind of thick, so it doesn't bend very well. We've been straightening it out for a couple days, but it's still slightly wavy. We need to get it into a solid position. The plan is to support it on some boxes, and maybe tape it down so it holds it's form.But, there is a part in the rollercoaster where it needs to be extremely straight. Any ideas??

- Heat it where you want the bend. If it is small tubing and depending on what it is made of, place where you want the bend to be in boiling water, take it out, bend it to shape and hold it there until it cools. If it is of a better material or thicker, wrap it with aluminum foil and hold it over a candle, but beware that it will get very hot and may start to melt. P.S. After reading again, you want to straighten it, so you will need to heat it and then roll it back and forth slowly until it cools.

Send your message to us

Plastic Tubes - PPR Pipes and Fittings for Industrial Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords