Plastic Tubes for PPR Pipe in Landscape Irrigation and Drainage System 2024

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Specifications

1.Material : PPR

2.Color: White, Gray, Green, or as you required.

3.Size: 20-110mm

4.Logo:customized

5.MOQ: 500pcs

6.Samples Time: (1)4-5days-If you want to customize your logo.

(2)1day-For our existing samples for reference.

7.OEM Accepted Yes

8.Certification available: Yes

9.Packing Details: Weaving Bag

Advantages

1)100% excellent raw materials ,safe and hygeian .

2)Drinking water pipeline system.

3)Recyclable ,benefit to the environment

4)Resistance to abrasion and corrosion.

5)Connected by heating ,leakage prohibit

6)Long lifespan,Minimum 50 years life time at 60 or 70°C and 10 bar maximum pressure.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

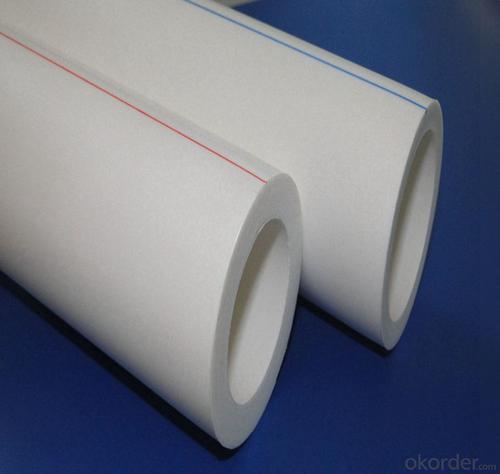

Product Show

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: What are the different types of plastic tubes available?

- There are several different types of plastic tubes available, including PVC (polyvinyl chloride), PE (polyethylene), PP (polypropylene), and PET (polyethylene terephthalate). These tubes can vary in size, thickness, and color, and they are commonly used for applications such as packaging, plumbing, electrical insulation, and medical devices.

- Q: What's the function of the plastic tube in this crown beam?

- Because the screw to pass through the concrete cover, casing, Chaimo screw can be conveniently taken out. The exposed part of the tube will eventually be removed, and the tube will be poured into the mortar to smooth it out.

- Q: Why do all squeeze tubes have a square at the top?

- Do you mean at the portion furthest from the opening with the cap? Because the tube is filled from the end that is furthest from the opening with cap. Years ago (before flexible plastics existed) all tubes were made from a thick aluminum foil, the cap was put on it, the tube was filled from the opposite end from the cap, and the tube was sealed after filling by folding the open end over a few times and crimping it, which always produced a square end. Now adays with plastic tubing, which is sealed by melting the tube end together you could make it have pretty much any shape, but due to tradition a square end is still used, because that is what customers are used to buying.

- Q: Can the plastic water supply pipe be heated by electricity?

- In long-distance transportation, the use of deep burial or insulation can generally guarantee that the ice will not be frozen, while in the local part of the ground to strengthen insulation, generally can not freeze. If the pipeline is not used for a long time, it is better to empty the waterways

- Q: What are the advantages of using plastic tubes in the electrical packaging industry?

- There are several advantages of using plastic tubes in the electrical packaging industry. Firstly, plastic tubes are lightweight, making them easy to transport and handle. Secondly, they provide excellent insulation properties, protecting electrical components from damage and ensuring safety. Additionally, plastic tubes are durable and resistant to corrosion and moisture, making them suitable for various environments. They are also cost-effective compared to other materials, allowing for lower production costs. Lastly, plastic tubes can be easily customized in terms of size, shape, and color, providing flexibility in design and meeting specific packaging requirements.

- Q: What are the different ways to cut plastic tubes?

- There are several ways to cut plastic tubes. Some common methods include using a sharp knife or scissors, using a hacksaw or a fine-toothed saw, using a tube cutter specifically designed for plastic, or using a heat tool to melt and separate the tube. The method chosen depends on the specific type and thickness of the plastic tube and the desired precision of the cut.

- Q: Im currently looking for some plastic non toxic tubing for drinking hats to drink from. I prefer it to be a store locally. I know there are available tubes online but I dont want to order it from the internet. Can anyone popup a very well known store that sells plastic tubing (good length)? Preferably close to Vegas...

- go to Ace hardware store and get what you need

- Q: Hot melt construction technology of PPI plastic pipe

- The hot melt tool is connected to the power supply and can start operation until the working temperature indicator is bright;

- Q: Suppose that you have an acrylic box containing water inside, as well as a submersible water pump and tubing. Also assume that you have a viable source of energy to turn the pump on.

- A really simple solution I devised years ago for an application my employer had to connect through a plastic container was to use silicone rubber hose and a short piece of nylon air hose over which the silicone rubber hose could be fitted. To use, simply drill a hole through the plastic container, and then push the end of a piece of tubing connected to the pump outlet, to extend say about 10mm. outside the container. Then you wet the short piece of nylon tube, and push it into the end of that hose, and that will make a watertight connection through the tank wall. Then you simply slip another piece of silicone tubing onto the projecting end of the nylon tube. Job done. Many thousands of products using this style of cheap through connection were made, and there were absolutely no failures. They are still going strong to this day. Using clear (natural) silicone rubber tubing, such as medical tubing or natural industrial grade is fine. We had problems when we changed to a white tubing at one stage, as the white disintegrated with time when used with water from some locations. The key to success IS the silicone tubing. Plastic tubing hardens with age, and could therefore leak eventually.

- Q: What are the different materials used to make plastic tubes?

- The different materials used to make plastic tubes include polyethylene, polypropylene, PVC (polyvinyl chloride), PET (polyethylene terephthalate), and polystyrene.

Send your message to us

Plastic Tubes for PPR Pipe in Landscape Irrigation and Drainage System 2024

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords