Plastic Tubes PPR Elbow for PPR Tubes DIN Standard from Top Chinese Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 14000 pc

- Supply Capability:

- 870000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

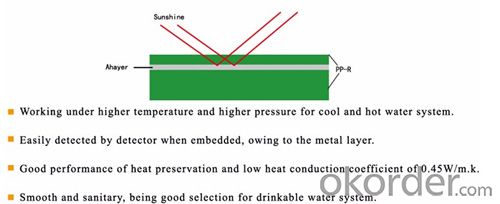

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Advantages and disadvantages of PPR pipes

The full name of PP-R pipes with an international level of new energy-saving plastic products in the nineties is the random copolymer polypropylene piping. PPR installation and use of the advantages and disadvantages are as follows:

Advantages:

1. Harmless to human health, to all ions in water and chemicals in the building are no chemical reaction, compared with metal pipes do not rust, plastic water pipe will not corrode, and has a high degree of acid resistance and chloride resistance.

2. Belonging to the sustainable development green products. There is no environmental pollution in the process of production, construction and use. Secondary recovery can be repeatedly used.

3. Are different, homogeneous melt PP-R pipe is connected with other pipeline is the biggest advantage of this pipe system. Pipe connections disclose rate is very low, no maintenance, usable visual inspection, the joint firm could no corrode.

4. Light weight, easy handling construction, can greatly reduce the labor intensity, fast construction progress.

5. Good heat resistance: instant use temperature can reach 95 degrees. Long-term use at work pressure does not exceed 0.6Mpa, temperature up to 70 degrees. To meet the general needs of life and production of hot water, it is an ideal hot water pipe.

6. Low thermal conductivity: thermal conductivity of 20 degrees was 0.23 ~ 0.24W / Mk, much smaller than steel and copper. Used in air conditioning or hot water supply and drainage, you can save the investment in the pipeline insulation.

7. Elastic modulus is small: stress due to temperature change is small, suitable for direct burial, in-wall and floor surface layer Concealed way. With High-grade appearance, it is a trend of fashion.

8. Small pipe resistance: pipe wall smooth, non-furring, small head loss, head loss is smaller than the metal pipe; the local head loss is also smaller than the metal tube.

9. Performance can be repaired pipeline: full advantage of PP-R pipe hot melt, the use of PP-R of the eye of a needle stick fill holes in the pipeline repair can also be cut out the damaged pipe replacement pipe.

Disadvantages:

1. Higher cost: With the continuous promotion of the pipe is now ready to accept the price, but the price is still too high, pipe fittings, because one mold imports; Second, copper and stainless steel fittings materials pipe fittings are used in special requests these metals temperature coefficient and accessories for a temperature coefficient of PP-R materials strict consensus, now also need foreign imports.

2. PPR size is only a small outer diameter of 20-110 mm diameter products; types of fittings and valves missing, there is connected to the metal valves inconvenient questions.

3. Rigidity and impact resistance worse than metal pipes.

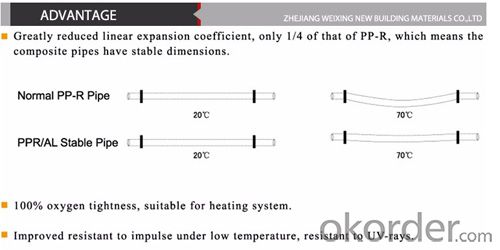

4. Larger coefficient of linear expansion, for surface or overhead required to lay more pipe hangers, affect the appearance.

5. Construction equipment advanced complex, construction technology requirements, construction workers and construction quality management requirements high. Joint quality and temperature of the hot melt connection, heating time, the seam stress-related, construction prone to bias.

6. UV resistance is poor, in the long sunlight easy to aging.

7. PP-R pipe belonging to combustible materials, it cannot be used for fire water supply system.

- Q: What are the different closure options for plastic tubes?

- The different closure options for plastic tubes include screw caps, flip-top caps, snap-on caps, and squeeze caps.

- Q: Can plastic tubes be used for packaging chemicals?

- Yes, plastic tubes can be used for packaging chemicals. Plastic tubes are often used for packaging chemicals due to their durability, resistance to corrosion, and ability to prevent leakage and contamination. Additionally, plastic tubes can be easily molded into various shapes and sizes to suit different packaging needs.

- Q: Are plastic tubes resistant to UV degradation?

- Yes, plastic tubes can be resistant to UV degradation depending on the type of plastic material used. Certain plastics, such as PVC (polyvinyl chloride) and HDPE (high-density polyethylene), are specifically formulated to have UV stabilizers that protect against degradation caused by exposure to sunlight. However, not all plastics are inherently UV resistant and may require additional coatings or additives to enhance their resistance to UV degradation.

- Q: Can plastic tubes be bent without breaking?

- Yes, plastic tubes can be bent without breaking, depending on the type of plastic and its flexibility. Some types of plastic, such as polyvinyl chloride (PVC) or polyethylene, have a certain degree of flexibility that allows them to be bent without breaking. However, other types of plastic, like acrylic or polycarbonate, are more rigid and may be prone to breaking if bent forcefully.

- Q: What is the best re-cycling method for plastic bottles & tubes?

- there is an industry located in Sumter, SC named Clor-Fi that recycles plastic bottles, etc by melting them down and extruding the material into carpet yarn. The company has been here doing this for 20+ years.

- Q: He was talking about dope before he offered me a smoke, but when he offered me a smoke from his clear plastic tube, I asked what it was, and if I remember right he said Marijuana.He had to use his glasses to push whatever was in it to the end.I had never been high before, my heart was racing, and I was VERY talkative and loud.

- Marijuana isn't smoked in a glass tube, it may be used in a hookah or a rolled cigarette, but not glass tube or pipe. That is usually crack cocaine or meth. I won't offer advice, but that friend put your life in danger, first not telling you, and second, giving you something so addictive.

- Q: Can plastic tubes be used for cosmetic packaging?

- Yes, plastic tubes can be used for cosmetic packaging.

- Q: I have a number of plastic tubes of differing sizes that I need to sand the full length of the inside of. The smallest one is less than a centimeter in diameter. I have some long paintbrush handles that fit very well inside, so I've tried to wrap sandpaper around them and insert them into the tubes, but I don't know of a way to sufficiently attach the sandpaper to the brush handles (and getting rolled up sandpaper stuck inside a thin plastic tube is VERY difficult to remove, let me tell you...). Can anyone offer me any help on this?

- force balls of steel wool thru the tubes from both ends with the paintbrush handles

- Q: Explain using the kinetic theory of matter.

- Metal tubes are not necessarily better suited. It is application dependant. They are more robust meaning in general they can support more pressure. Copper is an excellent thermal conductor. Plastic is lighter à, can flex much more… If weight is no issue, then for sure go with copper! It also depends on very many factors like temperature, pressure, chemical compatibility... Hope this properly answers your question Guru

- Q: Our hamster loves to make a bed in the plastic tube and not in the bed I bought (typical!). We clean the cage once a week and empty the tubes. Should we do this or should we just leave all the sawdust where it is?

- If the tube smells or if your hamster urinates in it, definitively clean it. If it doesn't smell, you can leave it alone or clean it.

Send your message to us

Plastic Tubes PPR Elbow for PPR Tubes DIN Standard from Top Chinese Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 14000 pc

- Supply Capability:

- 870000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords