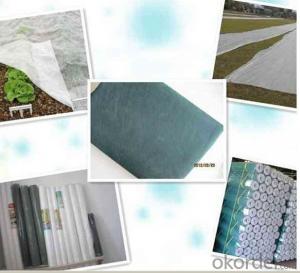

6 Oz PP Spunbonded Nonwoven Geotextile White

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FAQ :

1.What is your main products ?

Our main products are made from PE ,PP etc and could be used for agriculture and construction ,etc .

2.What is your payment term ?

We could accept TT ,LC.

3.What is your delivery time ?

The delivery time is around 30days per container, sometimes we have stocks .

pp spunbonded nonwoven fabric

Material

100% Polypropylene/100% PP

Color:Any color can be available

GSM(gram per square meter)

9-180GSM

Roll Width 4-320cm

Roll Length According to your requirement

Technics Nonwoven Spunbonded

Feature Waterproof, Mothproof, Eco-friendly, Non-toxic, Breathable, Anti-Bacteria

Usage Agriculture, Indrustry, Construction, Packaging,, Home-textitle, etc

Details

1MOQ 1 Ton

2 Loading Capacity

20’ Contain: 4 Tons

40’ HQ: 10-11 Tons

3Delivery Time

Within 7-15 days after 30% deposit is received or L/C

4 Payment Terms

1) T/T: 30% T/T in advance and balance 70% before shipping B/L copy

2) L/C at sight

1 Free Samples

2 Factory Supply

3 Competitive Price With High Quality

4 More than 20 years experience

- Q: What are the different geotextile installation techniques for landfill applications?

- There are several geotextile installation techniques commonly used for landfill applications. These include the direct burial method, where the geotextile is placed directly on the landfill surface and covered with soil or other materials; the geocomposite method, which involves placing a geotextile and a geomembrane together to create a composite liner; the anchor trench method, where the geotextile is anchored in a trench around the perimeter of the landfill; and the slope method, which involves installing the geotextile on the slope of the landfill to prevent erosion. Each technique has its advantages and is chosen based on the specific requirements and conditions of the landfill site.

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help in preventing erosion around culverts by acting as a barrier between the soil and water flow. They provide stability and reinforcement to the soil, preventing it from being washed away. Additionally, geotextiles help filter out sediment and prevent clogging of the culvert, ensuring proper water flow and reducing the risk of erosion.

- Q: How do geotextiles affect soil permeability?

- Geotextiles can improve or reduce soil permeability depending on the specific application and design. In some cases, geotextiles act as a filter, allowing water to pass through while trapping fine particles and preventing clogging. This can enhance soil permeability by preventing the formation of a dense layer that obstructs water flow. On the other hand, certain geotextiles can be designed to decrease soil permeability by acting as a barrier, preventing water from infiltrating or draining through the soil. Ultimately, the impact of geotextiles on soil permeability is determined by their purpose and the specific properties of the material used.

- Q: Related applications, product applications, industrial structure and distribution

- Road cloth, that is, geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile with excellent filtration, drainage, isolation, reinforcement, protection, with a light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. The application of geosynthetics originated in the 1950s, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple acupuncture non-woven geotextile" (GB / T -1998) standard, the current geotextile has been widely used in many areas. Geotextile mainly in the following three series: 1, acupuncture non-woven geotextile, specifications 100g / m2-600g / m2 between any choice, the main raw material is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture, Uses are: river, sea, lake embankment slope protection, reclamation, wharf, ship lock flood control and other projects, is through the filter to play a soil and water conservation and effective way to prevent piping. 2, acupuncture non-woven and PE film composite geotextile, specifications have a cloth a film, two cloth a film, the largest width of 4.2 meters The main raw material is to use polyester staple fiber non-woven, PE film through the composite , The main purpose is anti-seepage, apply to railways, highways, tunnels, subways, airports and other projects. 3, non-woven and woven composite geotextile, a variety of non-woven and polypropylene filament woven composite, non-woven and plastic woven composite, suitable for foundation reinforcement, adjust the permeability coefficient of the basic engineering facilities.

- Q: How do geotextiles help with ground reinforcement?

- Geotextiles help with ground reinforcement by providing a stable base for the soil, preventing erosion, and improving the overall strength and stability of the ground. They act as a barrier, distributing loads evenly and reducing the risk of settlement or subsidence. Additionally, geotextiles can separate different soil layers, allowing for effective drainage and filtration, which further enhances ground reinforcement.

- Q: What is the waterproof selection of artificial lake? How to build?

- Geotextile is the water, but the soil, from the role of anti-filter geomembrane is impermeable, like plastic film geotextile is a non-woven, as well as handbags, disposable health supplies, etc. I am the production of this wish smooth

- Q: How do geotextiles help with reinforcement of soil slopes?

- Geotextiles help with the reinforcement of soil slopes by providing a strong and stable layer that prevents soil erosion and increases the overall stability of the slope. These synthetic fabrics, placed within the soil, act as a barrier to distribute the load and improve the strength of the soil, reducing the likelihood of slope failure. Additionally, geotextiles can help with water drainage, allowing excess water to flow through while retaining the soil particles in place, further enhancing the reinforcement of soil slopes.

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve slope stability by providing reinforcement and erosion control. They are placed within the slope to act as a barrier against soil movement, preventing erosion and enhancing the overall stability of the slope. Additionally, geotextiles help to distribute loads more evenly, reducing the potential for slope failure.

- Q: How do geotextiles help with load transfer in foundation systems?

- Geotextiles help with load transfer in foundation systems by providing a stable and uniform platform for distributing the load from the structure to the underlying soil. They act as a separator, preventing the mixing of different soil layers and reducing the risk of differential settlement. The geotextiles also enhance the soil's strength and stability, thereby improving the overall load-bearing capacity of the foundation system.

- Q: What are the different factors to consider for geotextile selection in landfill applications?

- There are several factors to consider when selecting geotextiles for landfill applications. These include the type and composition of waste being disposed, the required strength and durability of the geotextile, its resistance to chemical and biological degradation, its ability to allow for proper water drainage, and its compatibility with the site conditions and construction methods. Additionally, factors such as cost, availability, and regulatory requirements should also be taken into account during the selection process.

Send your message to us

6 Oz PP Spunbonded Nonwoven Geotextile White

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords