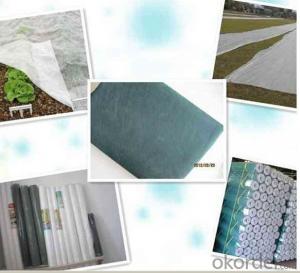

Colorful 50g PP Spunbonded Nonwoven Geotextile Pads

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.What is your main products ?

Our main products are made from PE ,PP etc and could be used for agriculture and construction ,etc .

2.What is your payment term ?

We could accept TT ,LC.

3.What is your delivery time ?

The delivery time is around 30days per container, sometimes we have stocks .

pp spunbonded nonwoven fabric

Introduction of polypropylene spunbond non woven fleece fabric is used to protect the crops in agriculture UV resistance masterbatch could be added 1%~8%. It can protect the vegetable crops and new lawns against extreme weather, animal and insect damage, yet allows light, water and air to penetrate, creating protected growing conditions..

| | |

Material | 100% Polypropylene/100%PP |

Width | 0.4--3.2M |

Color | Any color available |

Roll Length | According to your requirement |

Technics | Nonwoven |

Nonwoven Technics | Spunbonded |

Pattern | Yarn Dyed |

Weight | 9-200GSM |

Style | Plain |

Feature | Waterproof,Mothproof,Eco-friendly,Non-toxic,Breathable,Anti-Bacteria |

Certification | ISO9001 |

Usage | Agriculture,Indrustry,Construction,Packaging,Home-textitle, etc |

MOQ | 1Ton/1000KG |

Payment Terms | T/T or L/C |

Delivery Time | Within 7-15 days |

Packaging Detail | Plastic film in roll |

| Shandong,China |

Loading of Port | Qingdao |

Sample | Free samples are available |

- Q: How many meters from the river pipe trench construction using geotextile reinforcement

- River slope protection, etc. can use my professional production of geotextile products. Thank you

- Q: How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through a series of standardized tests and evaluations. These include physical properties testing such as tensile strength, tear resistance, and puncture strength, as well as hydraulic properties testing like permeability and filtration efficiency. Additionally, durability and chemical resistance tests are conducted to ensure the geotextiles can withstand long-term exposure to various environmental conditions. These rigorous quality assurance measures help to determine the performance and suitability of geotextiles for specific applications.

- Q: What are the key considerations for geotextile installation in cold climates?

- There are several key considerations for geotextile installation in cold climates. First, it is important to choose a geotextile material that is specifically designed for cold weather conditions. This ensures that the material will not become brittle or easily damaged in freezing temperatures. Additionally, proper site preparation is crucial, including removing snow and ice from the installation area to ensure a stable base for the geotextile. It is also important to properly anchor the geotextile to prevent shifting or movement due to freeze-thaw cycles. Overall, careful selection of materials and proper installation techniques are essential for successful geotextile installation in cold climates.

- Q: How do geotextiles help with asphalt pavement reinforcement?

- Geotextiles help with asphalt pavement reinforcement by providing a strong and stable foundation for the asphalt layer. They prevent the mixing of different soil layers, reducing the risk of settlement and rutting. Geotextiles also enhance the pavement's load-carrying capacity and increase its lifespan by distributing the load more evenly. Additionally, they help in reducing cracking and water infiltration, thereby improving the overall performance and durability of the asphalt pavement.

- Q: Are geotextiles resistant to insect infestation?

- Yes, geotextiles are generally resistant to insect infestation. Their synthetic materials and tightly woven structure make it difficult for insects to penetrate and nest within the fabric. However, some types of geotextiles may still be susceptible to infestation in certain conditions, so it is recommended to choose insect-resistant variants or take appropriate preventive measures if necessary.

- Q: Are geotextiles resistant to alkali degradation?

- Yes, geotextiles are generally resistant to alkali degradation. They are designed to withstand various environmental conditions, including exposure to alkali substances. This resistance ensures their durability and effectiveness in applications where alkali degradation may occur.

- Q: Can geotextiles be used in coastal revetment works?

- Yes, geotextiles can be used in coastal revetment works. Geotextiles are commonly used as a component in coastal revetment systems to provide erosion control and stabilization. They can help to reinforce the soil, prevent erosion, and enhance the stability of the revetment structure.

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by weaving continuous individual yarns together, creating a strong and durable fabric. On the other hand, non-woven geotextiles are made by bonding or felting together synthetic fibers, resulting in a fabric that is not as strong or durable as woven geotextiles. Woven geotextiles provide higher tensile strength, better filtration, and are typically used in applications that require greater longevity and stability. Non-woven geotextiles, while less durable, are often used for filtration and separation purposes due to their high water flow rates and ability to retain fine particles.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: Road overhaul of the original concrete pavement after shaving asphalt, anti-cracking is geotextile or geogrid more

- Generally used in the geotextile, generally used in soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green belt

Send your message to us

Colorful 50g PP Spunbonded Nonwoven Geotextile Pads

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords