High Temperature FMS Series Fiberglass Filter Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of High Temperature FMS Series Fiberglass Filter Bag

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton), Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of High Temperature FMS Series Fiberglass Filter Bag

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of High Temperature FMS Series Fiberglass Filter Bag

Compositions | P84/Glass fiber/PTFE | |

Weight(g/m2) | 800 | |

Thickness(mm) | 2.5 | |

Air permiability(m3/m2/min) | 8-15 | |

Tensile strength (N/5×20cm) | Warp | ≥3000 |

Weft | ≥3100 | |

Tensile Elongation(%) | warp | <10< span=""> |

weft | <15< span=""> | |

Broken strength (Mpa/min) | 3.85 | |

Working Temperature (°C) | ≤250 | |

Short time Working temperature (°C) | 270 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | Medial | |

Finishing treatment | PTFE treatment | |

| No. | thickness | air permeability (CM/S) | Breakingload | Continuous workingtempreture (℃) | weight | characteristic

| |

warp | weft | ||||||

FMS9801 | 1.80 | 15-40 | 1600 | 1400 | 200+300 | ≥800 | High temperature resistant |

FMS9802 | 1.80 | 15-40 | 1800 | 1600 | 200-300 | ≥800 | Corrosion resistant |

FMS9803 | 1.80 | 15-40 | 1800 | 1600 | 200-300 | ≥800 | popular |

FMS9804 | 1.80 | 15-40 | 1600 | 1400 | 180-210 | ≥800 | Abrasion resistance |

FMS9805 | 1.80 | 15-40 | 1600 | 1400 | 130-250 | ≥800 | special Waste incineration |

FMS9806 | 1.80 | 15-40 | 1600 | 1400 | 200-300 | ≥800 | Anti-high temperature |

FMS9807 | 1.80 | 15-40 | 1600 | 1400 | 180-210 | ≥800 | Abrasion |

FMS9808 | 1.80 | 15-40 | 1600 | 1400 | 200-300 | ≥800 | exit<20mg/Nm2 |

FMS9809 | 1.80 | 15-40 | 1600 | 1400 | 200-300 | ≥800 | Special for Smelting |

FMS98010 | 1.80 | 15-40 | 1600 | 1400 | 80-150 | ≥800 | Resistance to condensation |

4. Application fields of FHigh Temperature FMS Series Fiberglass Filter Bag

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

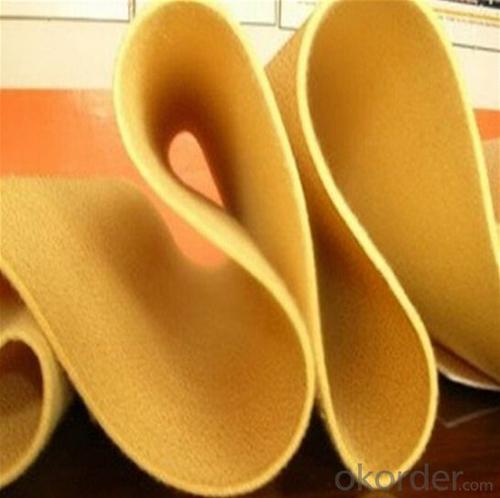

5. Images of FMS Filter Fabric for Dust Collection Bag

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: Dust filter bag filter material to go through how to process?

- Compared with the general woven twill fleece after is easy to form a layer of dust, dust collection rate is high (generally up to 99.5%); followed by heat setting to ensure the dimensional stability of fiber filter, filter maintenance and reliable work, deal with the media for heat setting; there is a hot rolling process can improve the needle density, the surface smaller pores, villi melt, smooth;

- Q: Is the filter area of the filter canister larger than the filter bag?

- In fact, no matter the dust filter cartridge or the filter bag, the main design is reasonable, so as to achieve the desired effect.

- Q: What are the characteristics of edible oil filter bag?

- Edible oil filter selection of filament fiber raw materials imported high pure acupuncture, with a special surface treatment to effectively prevent fibreshedding singeing, pollution filtrate, fluffy three-dimensional filtering uniform layer of solid and colloidal particles with high capture ability, long fiber high strength so that the efficiency of filtration stable filtering bag, longer service life. Edible oil filter material has high temperature resistant polytetrafluoroethylene (PTFE), polyester (PE), polypropylene (PP), nylon multifilament (NMO), etc., can satisfy the precision filtering 0.5~1000 micron range.

- Q: Do you have filter bags in the drum washing machine? My family has a dog, a dog on the clothes, the washing machine had the bag, after washing will not plug the drum of the small hole? What would you like to clean up?

- The drum washing machine also has a filter bag. It's at the bottom of the washing machine. The hair will be collected there. You'll see a small door on the ground where the washing machine is located. It contains a filter bag.

- Q: Figure out how to remove the Little Swan double cylinder filter bag

- Otherwise, to burnThe best thing to do is to contact the mall first. Your problem may be that the drainage hook is too tight. But for whatever reason, you shouldn't try too much, unless the mall staff ask for it. Anyway, customer service service is free, do not be afraid of trouble!!! 7 days 15 days

- Q: I was in Huizhou, there is a problem ask you heroes, is a common household washing machine, bag inside the drum has a white filter water. With a long time on the broken, I have been looking for many places can not find, who can tell you what? I believe many people also have this demand. Thank you

- Filter bag broken, the general border is good, you can make their own: waste will be stockings cut into the size of the appropriate bag, fixed to the border on the line.

- Q: When installing dust collector, how can you do not damage filter bag?

- 2 do not touch any metal or rough object until it is mounted to the flower board hole.3 use the protective cover provided by the supplier to prevent the filter bag from touching the edge of the flower plate hole when passing through the flower plate hole.

- Q: Did you use the filter bag when cooking the bones porridge?

- No, because the filter bags are decomposed at high temperatures to form substances that are detrimental to health. What's more, the filter bags in the market are not completely qualified.

- Q: Liquid filter bag should pay attention to those matters during installation

- 7, install the new filter bag, filter bag must be inserted into the basket, the filter bag sealing ring must be right to sit in the sealing groove.8. Test the gasket and choose the gasket that is compatible with the fluid. Close the lid, in particular, when the filter lid is closed, to ensure that the gasket is not twisted or from the groove, screw clockwise ring nut.9. Turn off the exhaust valve and turn on the pump switch. Open the inlet valve and slowly open the valve to see if it leaks. When the leak occurs, turn off the inlet valve immediately and start the outlet valve from the start again.Qi Qi reminded: this operation is best operated or directed by professionals.

- Q: How do you do if the filter bag is damaged in a large area?

- When the local bag is damaged, should stop all change (when the filter in the long-term work, fine dust accumulation in the filter layer permeability reduced, affect the system volume, although not damaged, it should stop all change), the best in the replacement of the bag precipitator suspend work at this time should be stopped ash cleaning controller is closed, open top manhole, and removable bag, when removed, the first bag cage out, then the spring ring of the upper opening of the cloth bag knead into a concave upward out of the bag, the bag in front of the new device, should be spent on clean dust clearing plate hole.

Send your message to us

High Temperature FMS Series Fiberglass Filter Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords