Polypropylene Geo Bag for Slop Engineering

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

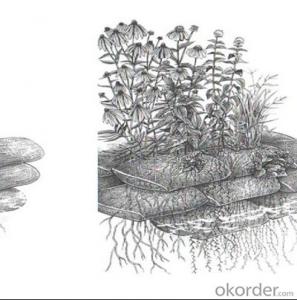

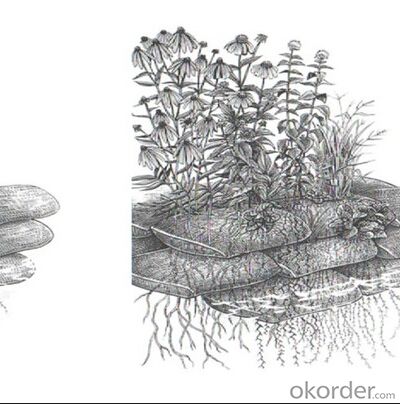

1,Brief Introduction of PP Geo Textile Bag for Slop Engineering

Geotextile bags that component is PP or PET needle punched non woven fabric

It is a greener environmental protection solutions used for erosion control ,embankment/slope protection and shoreline stabilization, stormwater management, and the creation of rain gardens and other functional green spaces.

color:white,black,deep green,grey,etc

Size:60cm*45cm,85cm*45cm,95cm*35cm,103cm*70cm,110cm*50cm,etc

2,Feature of PP Geo Textile Bag for Slop Engineering

Strong corrosion resistance ,UV resistance, anti-aging, non-toxic, non-combustion,good stability,split not extend etc. features.Anti-rot,anti-degradation,pests erosion resistance.

3,Package of PP Geo Textile Bag for Slop Engineering

Stardard export package or as per your request

4,Application of PP Geo Textile Bag for Slop Engineering

1).Ecohydraulic Engineering:

Natural environment for both sides of the ecological river, soil and water conservation,reservoir fluctuation zone regreening, wetland project, coastal engineering etc.

2.)Highway Engineering:

Roadbed side slope,retaining wall project, massif excavate side slope,bridgepier slope protection,culvert exits and entrances "Eight word" wall,sound protective screen, ecological isolation strip,swelled ground side slope,freeze thawing district side slope etc.

3).Railway Engineering:

Roadbed side slope,retaining wall project, massif excavate side slope,bridgepier slope protection,culvert exits and entrances "Eight word" wall,ecological beauty spot ecological district side slope,ecological fragile district ecological side slope etc.

4).Municipal garden engineering:

Massif regreening,massif excavate side slope,urban center ecological river bank,pack lakeshore,puente hills landfill,mine regreening,golf course,gardening landscape wall,

saline-alkali soil side slope etc.

5).Real estate landscape engineering:

Artificial landscape riverway,uptown side slope,gardening landscape wall,hydrophile retaining wall,roof greening ,etc

6).Others:

Slope body collapsed emergency manage,desert greening,natural reserves,the coast protection embankment,ammunition storage place,flood protection wall,ecological vertical wall etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of geo textile and geo bag etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- Geotextiles generally do not design applications in tunnel waterproofing. Because he can not meet the requirements of tunnel waterproofing

- Q: Geotextile cost how much money a flat

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: Is LDPE a geotextile or geomembrane? Answer!

- LDPE refers to the material, geomembrane LDPE material. Is a low-density poly-single-pole pole Li put pad lice bite of styrene made of geomembrane Huazhi geotextile material manufacturers

- Q: How do geotextiles help with load distribution in bridge approach fills?

- Geotextiles help with load distribution in bridge approach fills by acting as a separator and stress reliever. They prevent the mixing of different soil layers, reducing the potential for differential settlement and allowing for uniform load distribution. Additionally, geotextiles help to reinforce the soil, improving its overall strength and stability, which ultimately enhances the load-bearing capacity of the bridge approach fill.

- Q: What are the cost implications of using geotextiles?

- The cost implications of using geotextiles can vary depending on factors such as the type and quality of the geotextile, the size of the project, and the specific application. In general, geotextiles can add an additional cost to a project, as they need to be purchased and installed. However, they can also provide cost savings in the long run by reducing the need for expensive soil stabilization measures, increasing the lifespan of structures, and minimizing maintenance and repair costs. Additionally, geotextiles can provide cost-effective solutions for erosion control, slope stabilization, and drainage, which can help prevent costly damages and disruptions.

- Q: What are the factors to consider when designing geotextile-reinforced walls?

- When designing geotextile-reinforced walls, there are several factors that need to be considered. Firstly, the strength and stability of the geotextile material itself is crucial. The geotextile should have sufficient tensile strength and durability to withstand the loads and pressures exerted on the wall. Secondly, the soil characteristics and properties must be thoroughly analyzed. Factors such as soil type, compaction, and shear strength are essential in determining the design of the reinforced wall. The slope of the site and the anticipated slope stability also play a significant role. The angle of inclination and the height of the wall will impact the design and reinforcement requirements. Additionally, proper drainage is vital to prevent water buildup and potential failure of the wall. The design should incorporate adequate measures to ensure effective water management and prevent hydrostatic pressure. Considering the environmental conditions is essential. Factors such as temperature variations, freeze-thaw cycles, and corrosive substances in the soil must be taken into account to ensure the longevity of the geotextile-reinforced wall. Lastly, construction techniques and maintenance requirements should be considered during the design phase. The ease of installation, access for maintenance, and potential future repairs should all be evaluated to ensure the practicality and sustainability of the reinforced wall.

- Q: The outside of the blind tube is not to be with the geotextile 1 effect will be better?

- Plastic blind ditch is a new geosynthetics, is composed of plastic core wrapped outside the filter composition. At present the plastic core has several different cross-sectional shape rectangular, hollow rectangular, circular and hollow circular species structure of the plastic blind ditch products. Pass the water to see the original tie & gt; & gt;

- Q: What is the waterproof selection of artificial lake? How to build?

- Geotextile is the water, but the soil, from the role of anti-filter geomembrane is impermeable, like plastic film geotextile is a non-woven, as well as handbags, disposable health supplies, etc. I am the production of this wish smooth

- Q: Geotextile cloth and no square what meaning

- Geotextile, also known as geotextile, originated in the twentieth century, the fifties. Raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. Geotextiles are woven and non-woven. Not "Square", it is divided by the manufacturing process, the use of textile technology made of geotextile called spinning, and vice versa for non-woven geotextile. Due to the low cost of spinning geotextile, the cost is slightly higher. Most of the current engineering applications are non-woven geotextiles. They have a filter, filter, isolation, reinforcement, protection, and other functions.

- Q: Are geotextiles resistant to hydrolysis?

- Yes, geotextiles are generally resistant to hydrolysis.

Send your message to us

Polypropylene Geo Bag for Slop Engineering

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords