Strata Geotextile Polyester Geogrid PES Geogrid PET Geogrid Coated with Water Soluble PVC

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Polyester Geogrid PES Geogrid PET Geogrid Coated With Water Soluble PVC:

Polyester Geogrid adopts high strength, high modulus, and low shrinkage twisting industrial polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending among warp and weft direction. Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction. Then it forms into mesh size product after coated with high quality oil or water-soluble PVC which improves its strength, various technical standards and gives full play of its mechanical property.

Main Features of Polyester Geogrid PES Geogrid PET Geogrid Coated With Water Soluble PVC:

1. High strength, high modulus and low elongation.

2. Aging resistance and high tensile strength.

3. Pre-designed and easily combing with gravel and soil.

Specifications of Polyester Geogrid PES Geogrid PET Geogrid Coated With Water Soluble PVC:

Main specification:

1,High strength polyester geogrid Uniaxial Warp-knitting

2,High strength polyester geogrid Biaxial Warp-knitting

Polyester Geogrid Technical parameter:

1,Uniaxial geogrid

Performance/specification | PETG 35-20 | PETG 55-20 | PETG 60-30 | PETG 70-30 | PETG 80-30 | PETG 100-30 | PETG 120-30 | |

Stretching ratio %≤ | 13 | 13 | 13 | 13 | 13 | 13 | 13 | |

Intensity | Vertical | 35 | 55 | 60 | 70 | 80 | 100 | 120 |

KN/m | Horizontal | 20 | 20 | 30 | 30 | 30 | 30 | 30 |

Mesh size mm | 25*25 40*40 50*50 | |||||||

Width m | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Performance/specification | PETG-150-30 | PETG-200-30 | PETG-260-30 | PETG-300-30 | PETG-350-30 | PETG-400-50 | |

Stretching ratio %≤ | 13 | 13 | 13 | 13 | 13 | 13 | |

Intensity | Vertical | 150 | 200 | 260 | 300 | 350 | 400 |

KN/m | Horizontal | 30 | 30 | 30 | 30 | 30 | 50 |

Performance/specification | PETG-500-50 | PETG-600-50 | PETG-700-50 | PETG-800-50 | PETG-900-50 | PETG-1000-50 | |

Stretching ratio % | 13 | 13 | 13 | 13 | 13 | 13 | |

Intensity | Vertical | 500 | 600 | 700 | 800 | 900 | 1000 |

KN/m | Horizontal | 50 | 50 | 50 | 50 | 50 | 50 |

Mesh size mm | 25*25 40*40 50*50 | ||||||

Width m | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

2,Biaxial geogrid:

Performance/specification | PETG 30-30 | PETG 40-40 | PETG 50-50 | PETG 80-80 | PETG 100-100 | PETG 120-120 | PETG 140-140 | |

Stretching ratio %≤ | 13 | 13 | 13 | 13 | 13 | 13 | 13 | |

Intensity | Vertical | 30 | 40 | 50 | 80 | 100 | 120 | 140 |

KN/m | Horizontal | 30 | 40 | 50 | 80 | 100 | 120 | 140 |

Mesh size mm | 25*25 40*40 50*50 | |||||||

Width m | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Performance/specification | PETG 150-150 | PETG- 200-200 | PETG 260-260 | PETG 300-300 | PETG 350-350 | PETG 400-440 | |

Stretching ratio %≤ | 13 | 13 | 13 | 13 | 13 | 13 | |

Intensity | Vertical | 150 | 200 | 260 | 300 | 350 | 400 |

KN/m | Horizontal | 150 | 200 | 260 | 300 | 350 | 400 |

Performance/specification | PETG 500-500 | PETG 600-600 | PETG 700-700 | PETG 800-800 | PETG 900-900 | PETG 1000-100 | |

Stretching ratio % | 13 | 13 | 13 | 13 | 13 | 13 | |

Intensity | Vertical | 500 | 600 | 700 | 800 | 900 | 1000 |

KN/m | Horizontal | 500 | 600 | 700 | 800 | 900 | 1000 |

Mesh size mm | 25*25 40*40 50*50 | ||||||

Width m | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Applications of Polyester Geogrid PES Geogrid PET Geogrid Coated With Water Soluble PVC:

1. Strengthening soft roadbed of high-class roads and high speed railways, separating different

subgrade soil material.

2. Using in reclamation engineering, dam, landslides and retaining wall.

3. Enhancing various roadbeds.

4. Strengthening soft roadbed of airport.

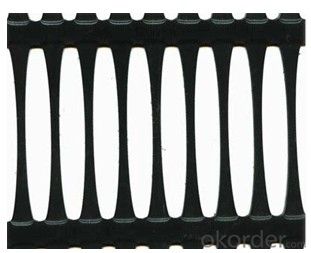

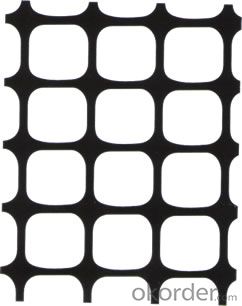

IMages of Polyester Geogrid PES Geogrid PET Geogrid Coated With Water Soluble PVC:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geotextiles improve the performance of drainage systems?

- Geotextiles improve the performance of drainage systems by providing filtration and separation, preventing the clogging of soil particles and allowing water to flow freely. They also enhance the stability and strength of the system, acting as a reinforcement layer to distribute loads and prevent soil erosion. Additionally, geotextiles can help control the migration of fine particles, increasing the longevity and efficiency of the drainage system.

- Q: What are the different installation guidelines for geotextiles in reinforcement projects?

- The installation guidelines for geotextiles in reinforcement projects typically involve preparing the subgrade, ensuring proper overlap and anchoring, and following specific placement techniques. The subgrade should be properly compacted and free from any debris or sharp objects. The geotextile should be installed with sufficient overlap to ensure continuous coverage, and should be securely anchored to prevent movement. Special care should be taken during placement to avoid wrinkles, folds, or damage to the geotextile. Overall, following manufacturer's recommendations and industry best practices is crucial for successful installation of geotextiles in reinforcement projects.

- Q: Are geotextiles suitable for use in geogrid reinforced slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced slopes. Geotextiles are often used as a separation and filtration layer in geogrid reinforced slopes to prevent the mixing of soil layers and ensure proper drainage, stability, and reinforcement. They help in distributing loads and reducing soil erosion, making them a valuable component in geogrid reinforced slopes.

- Q: Can geotextiles be used in landscaping?

- Yes, geotextiles can be used in landscaping. They are commonly used to control erosion, separate different soil layers, and provide stability to slopes or retaining walls. Additionally, geotextiles can be used as a weed barrier, allowing water to pass through while preventing weed growth in landscaped areas.

- Q: How do geotextiles help in preventing weed growth?

- Geotextiles help prevent weed growth by acting as a physical barrier that blocks sunlight, preventing weed seeds from germinating and growing. Additionally, they create an unfavorable environment for weeds by reducing moisture and nutrient availability, ultimately inhibiting their growth.

- Q: How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing strength, stability, and durability to the structure. They act as a barrier against soil erosion and provide a layer of protection for the geotextile tube. Additionally, geotextiles distribute the stresses evenly throughout the structure, improving its load-bearing capacity and preventing potential failures.

- Q: Geotextile now how much money? what is the price?

- Is to be based on market conditions, raw material prices, processing technology to determine the price of geotextile to Hongxiang Li Qian short wire geotextile, for example, t price is generally between 4900-7500 yuan / ton, but the weight of <200g , An increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: What is the geotextile for ditch drainage?

- Generally used polyester short wire geotextile, the specifications are 300g per square meter

- Q: Can geotextiles be used in the protection of underground tanks?

- Yes, geotextiles can be used in the protection of underground tanks. Geotextiles are commonly used as a protective layer to prevent damage to underground tanks from surrounding soil movement or external pressure. They provide an effective barrier between the tank and the surrounding soil, reducing the risk of punctures, abrasions, and corrosion. Additionally, geotextiles can help with filtration and drainage, ensuring proper functioning and longevity of the underground tank.

- Q: JTGF80 / 1-2004 "standard" 4.5 Geosynthetics in the treatment of the measured items in the "anchoring length", in the construction design diagram, the provisions of the value of the allowable deviation should be how to implement? Question added: Sorry! I missed a few words. When the construction design is not indicated, the specified value, the allowable deviation value should be implemented? JTGF80 / 1-2004 "standard only write to meet the design, construction requirements. I did not say that the design of the length of the anchorage is how much, can not find the construction technical specifications. So I do not know the provisions of the value of how to allow deviation? More

- Specifically not less than the specified value, does not exceed the allowable deviation. This is the so-called construction by specification! You refer to JTG assessment standard -2004 is correct! I have the data to let you refer to the next / geogrid and geotextile landscape is greater than or equal to 50cm, vertical is greater than or equal to 150com

Send your message to us

Strata Geotextile Polyester Geogrid PES Geogrid PET Geogrid Coated with Water Soluble PVC

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords