Polishing Aluminum Profiles for Radiator Covers Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Polishing Aluminium Profiles Manufacturer Description:

Polishing Aluminium Profiles Manufacturer (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of thePolishing Aluminium Profiles Manufacturer:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

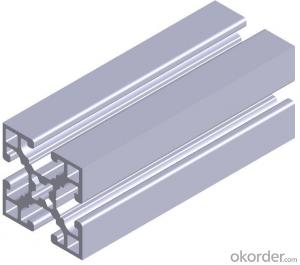

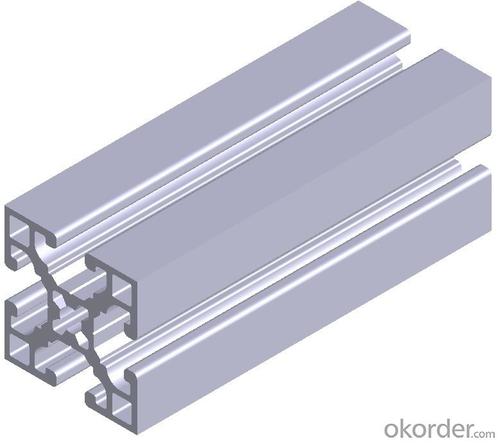

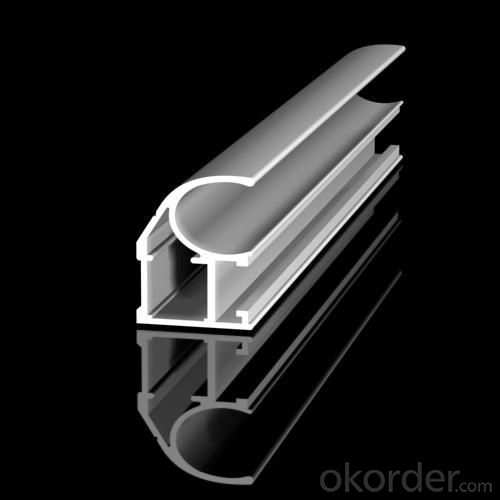

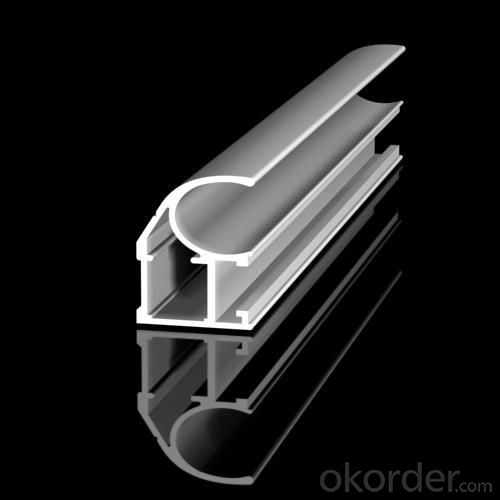

3.Polishing Aluminium Profiles Manufacturer Images:

4.Polishing Aluminium Profiles ManufacturerSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular material choice for HVAC applications due to its many advantageous properties. It is lightweight, making it easier to handle and install. Aluminum is also highly resistant to corrosion, which is crucial for HVAC systems that are exposed to moisture and varying temperatures. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer. This makes it ideal for heat exchangers and other components in HVAC systems. Overall, aluminum sheets are a reliable and durable option for HVAC systems.

- Q: Can the aluminum sheets be used for manufacturing light reflectors?

- Yes, aluminum sheets can be used for manufacturing light reflectors. Aluminum is a highly reflective metal and is commonly used in various industrial applications, including the production of light reflectors. Its high reflectivity allows it to efficiently redirect and amplify the light, making it an ideal material for manufacturing light reflectors for applications such as lighting fixtures, automotive headlights, solar panels, and photography equipment. Additionally, aluminum sheets are lightweight, durable, and corrosion-resistant, which further enhances their suitability for this purpose.

- Q: I need to install hand rails around a hot tub and wonder if aluminum would work well.

- Bad idea, it will corrode. Better are pool rails made from steel and powder coated in white, or light, not chromed, so you don't get burned. You're welcome!!

- Q: This question asks about the impact of using aluminum sheets on the aesthetic appeal of a building.

- <p>Aluminum sheets can significantly enhance the appearance of a building due to their versatility, durability, and modern aesthetic. They offer a sleek, clean look and can be easily shaped into various designs, adding a contemporary feel. The material's resistance to corrosion and weathering ensures that the building maintains its appearance over time. Additionally, aluminum sheets can be coated with various colors and finishes, allowing for customization and the ability to blend with or stand out from the surrounding architecture.</p>

- Q: Can aluminum sheets be stamped or engraved?

- Aluminum sheets possess the capability to undergo stamping or engraving procedures. Aluminum, being a versatile material, can be easily manipulated through various techniques such as stamping and engraving. Stamping entails the utilization of a stamping machine to press a design or pattern onto the surface of the aluminum sheet. This technique finds extensive usage in industrial settings to generate embossed or raised designs. Conversely, engraving encompasses the act of carving or etching a design onto the aluminum surface using a specialized engraving tool. This method is frequently employed to create intricate and precise designs or to incorporate personalized markings onto aluminum sheets. Both stamping and engraving can be employed on aluminum sheets to accomplish diverse decorative or functional objectives.

- Q: after putting aluminum sheet into the area between magnet and iron products, could magnet attract iron again?

- magnet can attract iron if the aluminum sheet isn't too thick. Because aluminum can't cut off magnetic line of force, unless aluminum sheet's thickness surpass the range of magnetic attraction.

- Q: I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets can vary depending on the thickness of the sheet and the specific alloy being used. However, in general, a typical bend radius for aluminum sheets ranges from 0.8 to 2 times the thickness of the sheet.

- Q: This question asks for signs or indicators that would suggest whether a roof needs to be replaced or repaired using aluminum sheets.

- <p>To determine if your roof needs replacement or repair with aluminum sheets, look for the following signs: visible rust or corrosion, especially on the seams and fasteners; sagging or buckling in the roof surface; leaks or water damage inside your home; and excessive noise during rain or wind. If the damage is widespread or the roof is old, replacement might be necessary. However, if the damage is limited to specific areas, repairs could suffice. It's always best to consult with a professional roofer for an accurate assessment.</p>

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- Aluminum foil will absorb heat, just like any other metal (and anything for that matter, but this isn't a discussion about conductors vs. insulators). Whether aluminum foil absorbs heat is the essential issue here. A car gets hot in the sun as a result of the sunlight shining on the car. When the sun shines on a car, the light passes through the windows (because windows are clear) and is absorbs by the interior of the car (e.g. the seat cushions). The absorbed energy is given off as heat, which is trapped in the car (heat doesn't pass through windows like sunlight does). By putting aluminum reflectors in your windshield, you are reflecting away the light and preventing it from reaching the interior of your car. For this reason, putting aluminum shielding in the windows of your car actually keeps your car cooler, and not hotter.

Send your message to us

Polishing Aluminum Profiles for Radiator Covers Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords