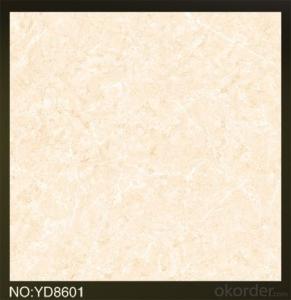

Polished Porcelain Tile CILO26602

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information of Polished Porcelain Tile CILO26602:

1.Size:60x60/80x80cm tile

2.Certificate:CE ISO

3.W.A. <0.5%

4.Material:Porcelain

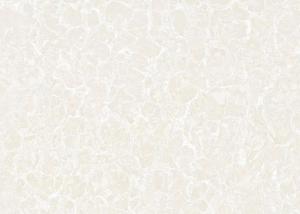

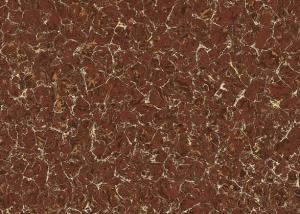

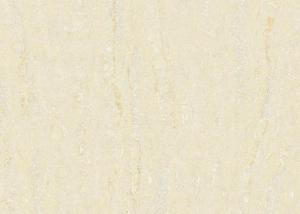

Features of Polished Porcelain Tile CILO26602:

1. Size:600*600mm;800*800mm Porcelain tile

2.Various colors are available;Fashion and elegant pattern tile

3. Usage: use in Inner Floor.

4. Engobe(water proof)

5. Certificate:CE;ISO;SONCAP

6.Tile Minimum order: 1x20'FCL (items we have in stock can be mix loading)

7.Delivery Time : within 25 days after received 30% payment by TT

8.Payment term: L/C; T/T, 30% deposit, balance paid before loading.

9.Packing: standard carton with wooden pallet or per customers' request

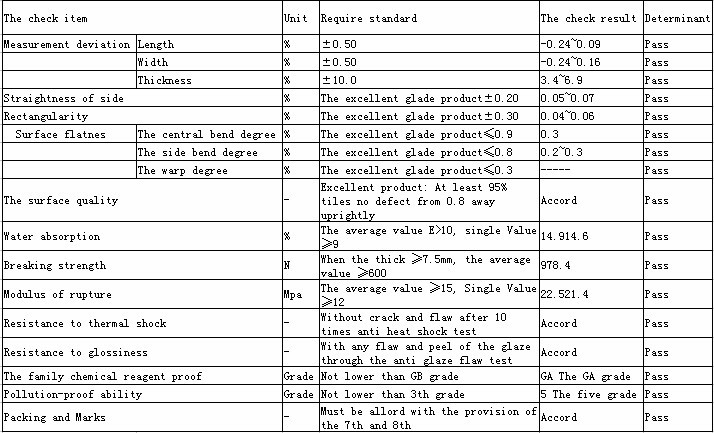

Specification of Polished Porcelain Tile CILO26602:

Normal Size of Polished Porcelain Tile CILO26602:

600*600mm,800*800mm

Advantage Of Our Factory:

1.Very Competitive Price:

2. High Quality

3. Immediate Response

Main Export Markets:

- Eastern Europe

- North America

- Mid East/Africa

- Central/South America

- Asia

- Western Europe

- Austra

Production and Packing Pictures of Polished Porcelain Tile CILO26602:

- Q: I have recently glued mosaic (mirrior finish) tiles onto a wall of mine, however I have noticed a few tiles, have almost sorta withered away at the back, it also almost looks as if the mirror backing scraped away, now giving more of a clear look. I would now want to remove some of the tiles out, Would it be advisable to use a chisel and hammer, to chip away the tile, or is there anything I can use to repair the tile.Much Appreciated

- okorder nice

- Q: I am looking for an obsolete 8X8 ceramic tile I believe was made by Interceramic. It‘s described on my original sales slip from 1999 as IC WestPalm Surf It‘s solid white in color and has a slight pebble texture. I need to modify my kitchen some and don‘t want to tear up the entire floor to install new type tile. Any ideas how to find this tile if there‘s any left out there.

- I agree with Fred on this one! But I do want to offer some help, try adding a border to the existing tile by chipping some of the edge pieces out and adding a complimentary tile in the same size but a nice color maybe set at a diagonal. Hope this helps!

- Q: I just can‘t figure out how to get the holes through them to string them on the bracelet.I have a drill, but no access to a vice or clamp. It‘s also a really old drill and the bit looks bent. I just tried hammering holes in with nails, but it wouldn‘t even go in very far before splintering the tile.What do I do??

- use a very small and fine drill bit that will not chip your pieces from vibration, check your local Home Depot or Hardware store for the bits and drill.

- Q: I am ready to tile a kitchen island, it has the rough shape of HOME PLATE, though not pointy. What is the best way to cover those odds angles effectively? Should I butt two edge tiles together? Also, I am not fond of the 16th inch spacing in tiles, I prefer 1/4 in gaps...any issues for the top of counter. The sides will be 1/8th gap.AdamDeridder,La

- Thousands of sq. ft. of tile. Certainly an Angle grinder with a diamond wheel can give you the cuts and angels that might work in as close as the rest of the perimeter tiles. A decent grit grind wheel can be used carefully to round off. In some measure your success will depend on the type of tile. Ceramic is as stable as Porcelain, but the glaze is millimeters thick only. I haven't spaced at 1/16th ever. It isn't enough space for grout to ahdhere well enough. 1/8th or 1/4 is standard, and sanded grout, polymer based. Steven Wolf

- Q: I live in a single-level ranch style house but on a concrete pad. I am re-tiling the kitchen floor. Upon removing the old tile, I discovered a 15 lb. felt pad had been glued to the floor; on top of this pad was thin set; then the tile. I live in Bakersfield, CA which is a dry and arrid climate.

- As long as it's not ceramic tiles, if so, I'd tear off the tiles. If it's linoleum, make sure you have a good subflooring and knock yourself out! Fallow the recommendations of the spacing around the walls AND take the time to bring in your flooring and let it in the room it'll be used for at least 24 hrs to dilate with the room's temperature and humidity. Don't pile all the packs in one corner, they need to breathe.

- Q: Can you lay down those adhesive floor tiles on top of existing tiles? If so, what kind of prep do you need to do to make sure they stick properly. I‘m not sure what type of tiles are in place now, but they are similiar to the types used in schools and other institutions. Very cheap, flexible, and bland. I want to lay something down in place of them, but don‘t want to rip them up. Is that possible? Thanks!

- That partially depends on how heavy the tiles are and the reinforcement of your wall. I remember when asking about putting tiling in my kitchen that for large areas of wall tile you need a special drywall or wall reinforcement. You may also need a special adhesive to add in addition to the self adhesive since the floor tiles will be put up in a manner that they are not truly designed for.

- Q: 16 by 16 tiles

- Tile labor varies a bit from area to area, but you can figure in the $7 a s/f range for basic labor , thin set, grout and 1/2 cement board , which is generally need when installing over the common wood sub floors. Tile isn t figured in this price since a plain , average or discontinued tile can go from $1 a s/f to a very nice tile in that size at 4$ a s/f Extras such as rip out/ disposal and any floor prep isn t included either. Any questions you can e mail me through my avatar.. GL

- Q: I am making a movie for school and i need to hang things from our ceiling to the ground. The problem is is that the ceiling is an acoustic tile and i‘m not sure if it will hold enough. (This is one of the older acoustic tiles with all of the holes in them.

- Been there, done that... Can't happen. What you can do, however, is go to the hardware store and buy new ones OR if replacing them is out of the question, get a can of KILZ paint primer. It is the best stain blocker on the planet. Once you cover it with Kilz, it WILL still show through the Kilz, itself, but once you have one or two coats of regular pain over it, you will never see the blood again.

- Q: What is the best way to paint over brown wall tiles

- After thousands of sq. ft. of tile, and thousands of gallons of paint, (not together) and with all due respect to you and others; this is kind of like a CAN I? question. Tile is essentially glass. Certainly you CAN probably paint over, but may never truly be satisfied with the result, especially over any long term. Also with no offense at all, and not needling you over a misspelling, I had to chuckle at Pinting. I've probably done a lot of that too, and in fact probably while on or over tiles. Steven Wolf

- Q: I am in the process of installing a slate floor in my mudroom. The durock has been laid, and the tiles cut and sealed, and I‘m ready to start using the medium set to secure the tiles in place, but as I‘ve never laid slate (or any tile) before, I have some questions. 1. The tiles are in place now how I want them, do I have to take up the tiles row by row before I start mortaring them in place, or can I do 1 or 2 tiles at a time?2. I laid the tiles out starting from the center and working outwards. When I lay the tiles in place do I again start at the center, or do I start from the edges, or doesn‘t it matter?3. What is the best way to prevent lippage? As this is slate there is a good amount of variation. Do I just back butter each tile so that it is as high as the highest tile in the room? How do I manage to do that properly?

- Others might disagree, but here's what I suggest: 1. I take up at least a few rows of tile at a time, carefully stacking them in order. 2. Layout should always be done using a center line. There are options for the installation: - If you carefully snap or draw lines for each row on the Durorock and do not use spacers you can start wherever you want, for example against a far wall so that you don't work your way into a corner. - If you only use a center line and rely upon spacers, then you need to start at the center. Tiles tend to drift from each other slightly when you install using spacers, so if you start in the center and work in both directions the net drift toward the edge will be half as much as it would if you work from one edge all the way to the other. - I always draw lines for each row when I do a diagonal installation. I install the longest row first and the work away from it toward the opposite corners. 3. Once I mix a batch of thinset, I don't want to fuss much with tile thickness. So before I even lay the slate tiles out on the floor I sort them from thickest to thinnest. Individual tiles often vary in thickness from one corner to the other; others might have consistent thickness but be dished (not flat). These tiles are candidates to be cut for edge pieces, or they might not be worth using at all. Anyway, I layout the tiles from thickest on one side of the room to thinnest on the other and only need to butter a thin corner of that occasional irregular tile that is pretty enough to be worth the hassle. 4. See my answer to 2.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 90 Million |

| Main Markets | 8.00% Mid East 15.00% Northern Europe 15.00% North America 12.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 20.00% Southeast Asia 4.00% Oceania 3.00% Western Europe 2.00% Southern Europe Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008;CCC,CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan, China |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Polished Porcelain Tile CILO26602

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords