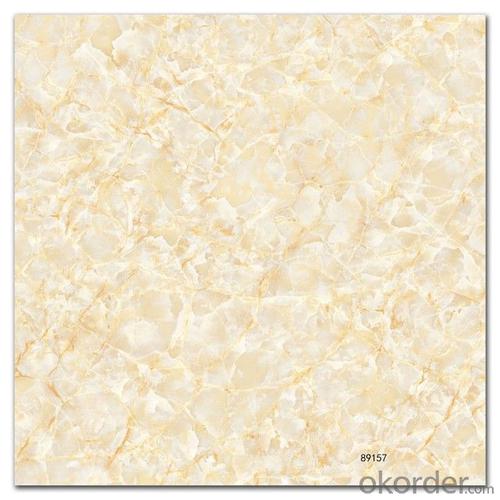

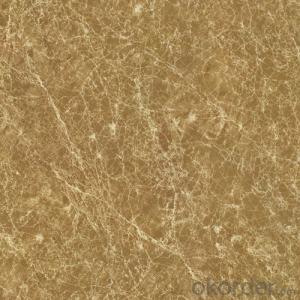

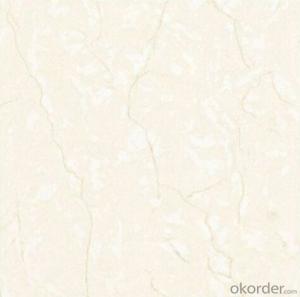

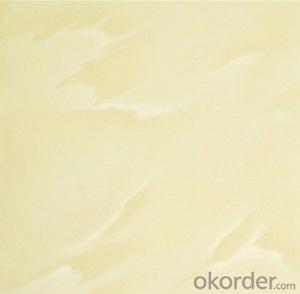

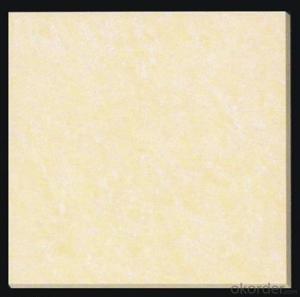

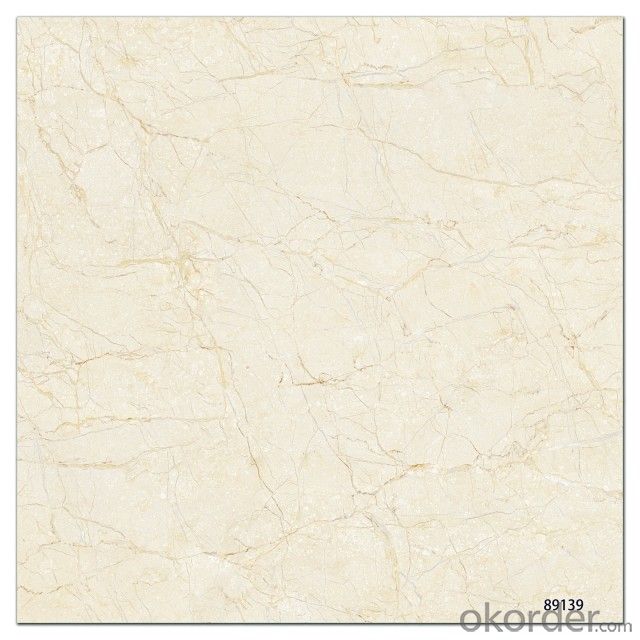

Polished Glazed Porcelain Tile The Beige Color CMAXSB1229

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features of Glazed Tile :

1. Material: glazed porcelain

2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government and corporate projects, flooring tiles, deluxe clubs flooring

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

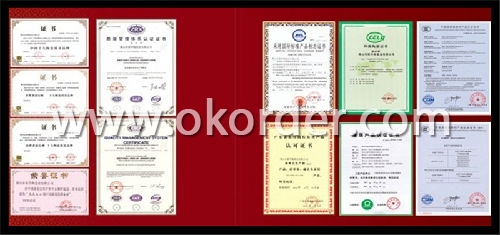

Primary Competitive Advantages of Glazed Tile:

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification:

Tile type: | Ceramic tile |

Material: | Porcelain |

Size(MM) : | 600x600mm |

Thickness(MM): | 9mm |

Water Absorption: | ≤0.5% |

Color: | Available in all designs and colors |

Usage: | Used in floor |

Surface treatment: | Glazed surface |

Features: | Professional triple-burning in oven, which makes our tiles more excellent quality. |

Function: | Acid-Resistant, Antibacterial, Heat Insulation, Non-Slip, Wear-Resistant, Anti-fouling easy to clean |

Packaging: | 600x600mm: 4pcs/box,28kg/box,standard cartons and wooden pallets packing |

Remark: | All kind of designs can be produced according to your requirements |

Quality | |

Surface quality: | 95% tiles no defect from 0.8 away uprightly |

Breaking strength: | As require |

Resistance to thermal shock: | Without crack and flaw after 10 times anti heat shock test |

Brightness: | ≥55 |

Frost-resistance: | No crack or spalling after frost resistance test |

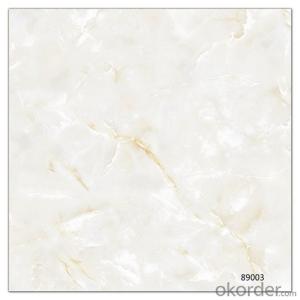

Product Picture:

Packing Pictures

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: I am replacing a floor furnace and may need to replace some tiles. These are nominally size 11-1/2 x 11-1/2 x 1/2 inch. Thanks.

- ooooh, good luck. Do you have a building material salvage company in your area? People who buy the fittings, etc in old buildings before demo. or remodeling.......are probably your best, if not only bet.

- Q: I want to lay tile on a house I just bought. What is the difference between ceramic and porcelain tile and which one would be the best fit for my house? The tile is going to be in the living room, dinning room, and kitchen. Also, how much is it going to cost me for labor to lay down the tile? Total square feet is going to be around 600 sq ft.

- I okorder /... As far as how much it will cost to install you will need to go to home depot or lowes and get an estimate. Call around locally or ask any neighbors that have had tile installed.

- Q: I have some extra granite tiles, and want to get them trimmed to the dimensions I want. I lack a wet saw, and don‘t want to buy one, so is there somewhere I can go to get it done?

- I'm pretty sure that a hardware store will do that for you like Lowe's or Home Depot. You would just need to pay for a cutting charge per piece.

- Q: the third tile. All three tiles types have the same side length. Determine the shape of the third tile type.

- Where 3 tiles meet, they must add up to a full 360°. The formula for the interior angle of a regular n-sided polygon is: ((n - 2)*180) / n Plugging in n=4, the interior angle of a square is 90° Plugging in n=5, the angle of a pentagon is 108° The angle of the third tile is x and the 3 angles must add up to a full 360°: 90 + 108 + x = 360 Solve for x: x = 360 - 198 x = 162 Plug that into the original equation and solve for n: ((n - 2) * 180) / n = 162 (n-2) * 180 = 162n n - 2 = (162/180)n n - (162/180)n = 2 (18/180)n = 2 (1/10)n = 2 n = 2 * 10 n = 20 So the third tile must be from a regular icosagon (20-sided polygon) Answer: Regular icosagon; see the picture below.

- Q: Behind my sink in the kitchen, I have a back splash that is white tile with an ugly floral pattern on about every other tile. Instead of replacing all the tile, I was thinking maybe I could somehow take off the floral stuff.I don‘t think it is like a sticker, I tried scrubbing it off with a magic eraser with no luck. Any ideas?

- i will try to know about question.then i will try to give it

- Q: Tomorrow I will be laying porcelain tile in my kitchen and need help in figuring out how to cut a hole in the tile for the floor vent? Any input would be appreciated.

- I've done this: I've used an angle grinder to cut a rectangle in one bathroom tile. Straight cuts are easy using an angle cutter and a diamond wheel designed for cutting tile. I've even cut a round hole for the commode. But the commode had a tile seam under it, so I wasn't cutting a hole in the middle of a tile, I was able to cut and nibble away until I had a semi-circle in each tile. Just make sure you have more tile than you need. If (when) you make a mistake you have more to work with. And don't try to accomplish the entire cut all at once. Take little passes at it until you work your way through. Hope this helps. 'av'a g'day mate. '')

- Q: I am getting ready to replace my kitchen flooring. It currently has sticky vinyl tiles, which I hate. I want a nice tile look for sure. However, it seems it is very hard work installing real tile, and more expensive. I have seen some laminate click together tile flooring that looks pretty good.Which one is best? Which one would last the longest? Any other insight? Thanks!

- Ceramic tile, properly installed will out last any flooring..You have your choice of ceramic, porcelains and even real stone, if thats properly sealed. Dropping something of properly prepped and installed tile will NOT crack it. You may top chip it but you would also damage any other flooring thats installed. Laminates ,of good quality will last a long time but the water factor and being in a kitchen is high risk. Sheet vinyl , as long as you don t get a base grade and get a decent product,, is also a good flooring.The new vinyls have better top coats and clean and last longer with warranties that last a long time. Tile is labor intense but the savings out weigh having it installed. You can install it yourself for the price of having some one else install vinyl. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Can I go over the exixting tile,or do I have to remove the old tile first.There is ceramic tile there now,and I want to intsall new ceramic tile.I hope this doesn't sound like a dumb question.

- You okorder /... Good Luck!

- Q: Hello! I currently have a 3 season sunroom addition on the back of my home that has been stripped down to the wood. I recently saw a 4 season sunroom that had tile down and needless to say, I fell in love with it! I am thinking about putting tile down in there but am worried about the weather...I live in Minnesota where it gets very cold...and that room is not heated in the winter. Would I have problems with the tile cracking? Or does anyone know of an alternative way to get a tile-looking floor without having to worry the temperature changes??

- Hi, In the UK we have a floor covering which is similar to the wood effect laminate floor, it locks together and looks amazingly like 9x9 tiles. I put it in my bathroom and it is not as cold as tiles to the bare feet. It is a wood/paper based product but is waterproof for the normal house hold duty. I assume that the Minnesota winter will not make it too cold. Use a styrefoam underlay 2mm thick to prevent heat loss. this is a do it yourself job if you are handy with a saw, We know it as TILE LOK

- Q: The tile I want to clean was built with the house back in the early 1900‘s but still in very good condition what would be the best way to clean that because its very dirty, and i think its porcealin. The second set of tile looks like it was put in back in the seventies but doesn‘t match the original tile at all, what would be the best way to change the color other than replacing it. Could i use pray paint?

- Generally I would recommend avoiding painting over tile. There are several excellent tile cleaning products available at your local hardware store; talk with someone at the store about your specific situation. If you MUST paint over the tile; you will want to treat it with some sort of an acid wash first to etch the surface so that the paint will stick. I strongly recommend that you put a couple coats of primer on first before you paint your color as the tile and grout will have notably different properties with respect to your painting job.

Send your message to us

Polished Glazed Porcelain Tile The Beige Color CMAXSB1229

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

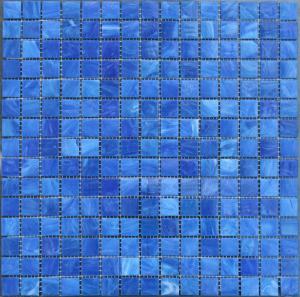

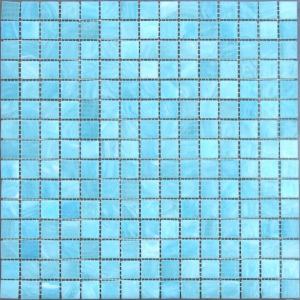

Similar products

Hot products

Hot Searches

Related keywords