Pneumatic Double Flange Butterfly Valve Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

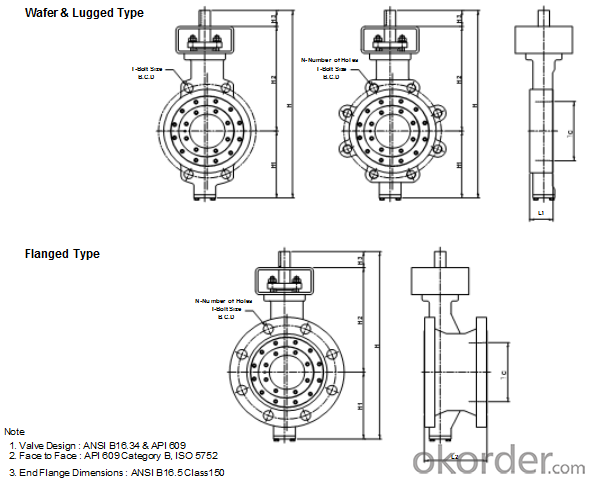

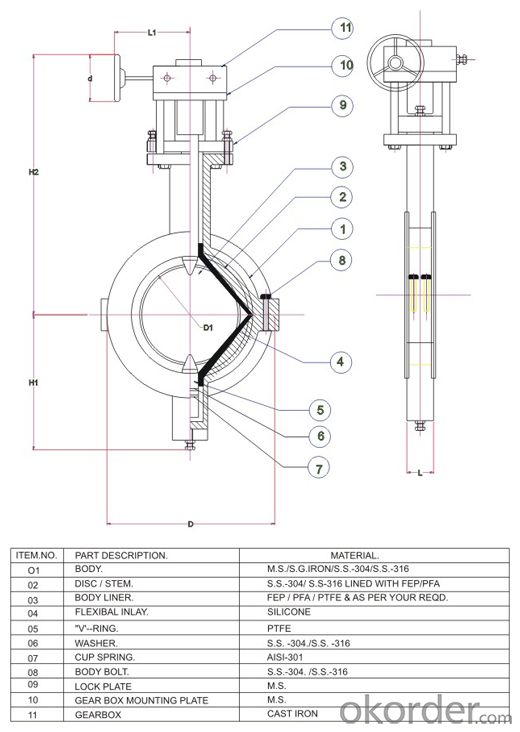

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.

- Q: High and low pressure valve is how to distinguish?

- Ultra high pressure valve nominal pressure PN = 100MPa; high pressure valve nominal pressure PN10.0MPa ~ 80.0MPa; medium pressure valve, nominal pressure of PN2.5MPa ~ 6.4MPa; low pressure valve, nominal pressure PN is less than or equal to 1.6MPa

- Q: Which industries need valves?

- Valve as a general component, widely used in various industries, but there are three main purpose of application in various industries:1, routine inspection needs;2, new projects supporting;3, emergency reserves.Valve market trendsDue to changes in user demand, the market trend of valve products will also change accordingly. In the future, the main trends are as follows:1 with the transfer of oil development to the mainland oil fields and offshore oil fields, and the power industry under the 300 thousand kilowatts of thermal power to more than 300 thousand kilowatts of thermal power and hydropower and nuclear power development, and valves should be changed based on device applications and the corresponding changes in its performance and parameters;2 urban systems generally use a large number of low-pressure valve, and to the development of environmentally friendly and energy-saving, low iron gate that is used in the past gradually shifted the environment-friendly plastic sheet valve, balance valve, metal sealed butterfly valve and the center line butterfly valve seal transition, oil and gas pipeline projects to develop in the direction, which in turn requires a large number of flat gate valve and ball valve the;

- Q: Valve category can fill the trunk door, branch valve Mody?

- Valve category refers to the type of valve, the big species are divided into: butterfly valve, gate valve, globe valve, ball valve, check valve, control valve, trap and electric valve,

- Q: G what's the meaning of the valve?

- Valve with other function or with other special mechanism, fill in a Chinese language before the valve type code number

- Q: What should be checked before using the valve?

- The valve must be tested before installationI. examination of documentsThe valve must check the quality documents before installation, the valve manufacturer should be nameplate, nameplate and the body should be the name of the manufacturer, valve type, nominal pressure, nominal diameter and logo, must comply with the "universal valve logo" GB 12220.Two, appearance inspection

- Q: The general signal valve installation, or other valve installation is not installed with the groove flange clamp hoop Yucca or direct way? What's the convenient way to install the following diagram? I don't understand. Neither groove, flange nor hoop. Thank you, sir!

- The blue one is the separate body, and the red one is the welded flange on the pipe. There is rubber on the valve body, and it can be sealed with flange. This is determined by the structure of the butterfly valve, usually DN150 of the small diameter butterfly valve are installed this way. It comes with flanges, but the prices are much higher. Small caliber general butterfly valve is generally used for low pressure, leakage requirements are not high, so rarely use its own flange. With flanges, it is generally used in petrochemical systems and has a much higher pressure level.

- Q: What is the purpose of the valve?

- Valve is a pipe accessory. It is a device used to change the direction of the passage and the direction of the medium flow, and to control the flow of the conveying medium.Valves have the following uses:1. Connect or cut off the medium in the pipe. Such as gate valve, globe valve, ball valve, plug valve, diaphragm valve, butterfly valve and so on.2 、 adjust and control the flow and pressure of the medium in the pipeline. Such as throttle, control valve, pressure reducing valve, safety valve, etc..

- Q: How do you calculate the flow of the valve?

- Valve flow calculation value is very vague, pipe pressure, back pressure, medium viscosity, medium temperature, valve structure, and so on, will affect the calculated value.

- Q: How can the material be checked by valve approach? What experiments do you need?

- May refer to the valve pressure test principle and the pressure test matters needing attention.(1) in general, the valve shall not be subject to strength test, but the body and bonnet shall be subjected to strength tests after the repair of the valve body and bonnet or corrosion damage. For the relief valve, the constant pressure and seat return pressure and other tests shall be in accordance with the specifications and the relevant regulations.(2) the installation of the valve should be done for strength and tightness test. Low pressure valve sampling 20%, if not qualified should be 100% of the inspection; medium and high pressure valve should be 100% of the inspection.(3) the installation position of the valve shall be in the direction of easy inspection during the test.(4) welding connection valve, not with blind plate pressure test can be used when the cone seal or O ring seal pressure test.(5) when hydraulic test, the valve air will be excluded as much as possible.(6) the pressure should be increased gradually during the test, and the pressure will not be sudden and sudden.(7) strength test and sealed test duration is generally 2~3min, important and special valves should last 5min. Small caliber valve test time can be a little shorter, large caliber valve test time can be longer. During the test, the test time can be extended if in doubt. Strength test, does not allow the body and bonnet sweating or leakage. Sealing test, the general rotor valve only once, the safety valve, high pressure valve and other raw valve to be carried out two times. When testing for the low pressure, large diameter valve is not important and there are provisions to allow leakage of the valve, allowing a small amount of leakage; the common valve, power station valve, marine valves and other valve requirements vary on leakage requirements according to relevant regulations.

Send your message to us

Pneumatic Double Flange Butterfly Valve Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords