Butterfly Valve Pneumatic Double Flange Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

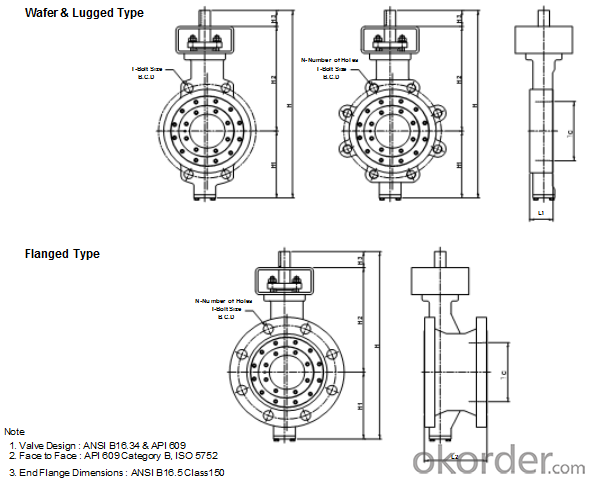

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Where is the Shandong valve? How about joint valves in Shandong?

- To find Shandong valve manufacturers, Shandong better valve manufacturers are in Weifang, find the valve factory is also simple, direct search "Weifang valve" is

- Q: What does the "XV" valve mean?

- XV if in front of the valve position, such as XV2211-011, then the XV indicates the switch valve, which is a representation of the Control Valve relative to the regulating valve.

- Q: What is the difference between valve j941H-40 and j41H-40?

- Valve design manual showsJ- stop valve9- electric4- connection means flange connection1- through typeH- sealing surface is alloy40- operating pressure is 4.0Mpa (or 40 kg)According to the comparison, we can see that the difference is that one drive mode is electric, one is transmission mode, and the other is manual. What do not understand, you can ask me directly. Two hundred and fourteen million two hundred and seventy-seven thousand eight hundred and fifty-one

- Q: I would like to ask, how specific treatment, and compared with the industry?.Is there a constructive answer?

- I have to do the technical sales colleagues is high inside out now before the inside sales revenue is also good about one hundred thousand a year as sales of a great degree of luck the.I do not know what the specific circumstances, what age, in this line for several years, there is the opportunity to communicate with the landlord and make progress together.

- Q: What are the major brands of valves abroad?

- Fisher (Emerson's brand, pneumatic head and regulating valve is good) mountain Wu (Japan's control valve is doing well)

- Q: Which valve can play a good regulatory role?

- A wide range of valves, the function is different, although like conventional butterfly valve, ball valve can play a regulatory role, but their role is not linear, so if you need to adjust the precision of the valve, it is best to select the control valve.

- Q: I'm going to put a solar energy and an electric water heater installed in the same hot water pipe, a valve, a valve open and close the valve B and vice versa the installation of solar and electric water heater, there can be no linkage valve?

- Yes, three ball valves (T and L) are two. Switch more complex point of the valve is basically ball valve, such as central air-conditioning commonly used to the four - way reversing valve.

- Q: Tell me the exact address, or the phone number in the market. Where is the industrial zone (the valve) in Hefei? Please help, thank you

- At the intersection of Mingguang Road and Shengli Road, the southwest side is all made of valves

- Q: Why is the valve on the pipeline not the same size as the pipe, and how much of a crude pipe can be given? Thank youI'm sorry, I didn't make it clear that when doing pipe work in the factory, for example, 60 of the pipe, and in this pipeline to install the valve to choose DN50, and so on.

- The pipe you choose is outside the 60 bar D60 pipe DN50 valve is right, such as D89 pipe with DN80, you are outside diameter and nominal diameter concept is not clear

- Q: What's the material of j41h-16p's valve?

- J41H-16P is: manual stainless steel flange, hard sealing stop valve, pressure 1.6MPa. Material: 304.

Send your message to us

Butterfly Valve Pneumatic Double Flange Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords