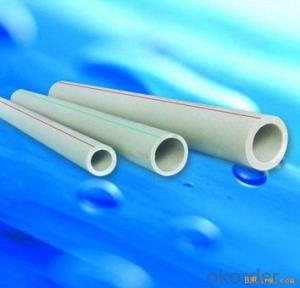

Plastic Tubes - 2024 PPR Pipes for Industrial and Agricultural Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe.

Packaging Details:

Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2 PE poly bag+ carton Delivery. Detail: 15 days/ 20" container; 25 days/ 40HQ

Packing:

1.Pipes in bar with the length 4m/5m/6m

2.Common pipes packedn in nylon bag.

3.Small size pipe can packed in big size pipe to save the area.

4.All in strong exporting packing.

Shipping :

1.Delivery date :7-15 days after order confirmed

2.100% delivery in time

3.LCL order confrimed

4.Shipped by express ,air or Sea.

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q: If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q.How can I get a sample?

A: FREE SAMPLE can be sent to you .Freight will be collect

Q. Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product, we will offer you the best design assistance.Pictures

Q:, Which factors can be customized?

A: Material, Color, Size, Packing ,Brand, delivery

Q; Advantages of your products?

A:Company products, good quality, high reputation guarantee.

- Q: Are plastic tubes resistant to ultraviolet light?

- Yes, plastic tubes can be made resistant to ultraviolet light by adding UV stabilizers or using UV-resistant materials during their manufacturing process.

- Q: Can plastic tubes be used for electrical wiring?

- No, plastic tubes cannot be used for electrical wiring as they lack the necessary insulation properties required for safe and effective electrical connections.

- Q: DN is the pipe a pipe or a plastic tube?

- PE (polyethylene) material is widely used in water supply pipe manufacturing because of its high strength, corrosion resistance, non-toxic and so on. Because it won't rust, it is the ideal pipe instead of ordinary iron pipes. PE due to its unique advantages and is widely used in building water supply, drainage, underground drainage pipe, building heating, gas pipelines, electrical and telecommunications, industrial protective casing pipes, agricultural pipes etc.. It is mainly used in urban water supply, urban gas supply and farmland irrigation.

- Q: I am in hollywood CA and I need a tornado tube, and I can not find it, what else can I use if I can not find that tube?

- We always used wide electrical tape. Works fine. [EDIT] MacGuyver was a tv show from the 80s. This guy could do anything with whatever he found lying around. You should totally check it out.

- Q: What are the advantages of using plastic tubes in the automotive industry?

- There are several advantages of using plastic tubes in the automotive industry. Firstly, plastic tubes are lightweight, which helps reduce the overall weight of the vehicle and improve fuel efficiency. Secondly, plastic tubes are corrosion-resistant, making them more durable and long-lasting compared to metal tubes. Thirdly, plastic tubes are easier to install and manipulate, allowing for more flexible and efficient design options. Additionally, plastic tubes have excellent thermal and electrical insulation properties, making them suitable for various automotive applications.

- Q: Can plastic tubes be used for storing powders or granules?

- Yes, plastic tubes can be used for storing powders or granules.

- Q: Are plastic tubes suitable for plumbing applications?

- Yes, plastic tubes are suitable for plumbing applications. They are commonly used in residential and commercial plumbing systems due to their durability, corrosion resistance, and ease of installation. Plastic tubes such as PVC (polyvinyl chloride) and PEX (cross-linked polyethylene) are widely accepted and meet industry standards for plumbing installations.

- Q: How can plastic pipes be connected to steel valves?

- Valve such as flange valve, then PVC-U pipe and valve connection should be flange connection. Connecting with the plastic pipe and flange with flange bonding, also can use hemmed or band.(2) connect the PP-R tube and the valve threaded valve valves such as: 1) is, should use external thread transition joints, the transition joints at one end of the external thread, the other end is connected with hot melt socket PP-R plastic pipe.2) the valve, such as the external thread valve, should use the internal thread transition joint, one end of the transition joint is internally threaded, and the other end is a socket which can be connected with the PP-R plastic pipe by hot melting.3) valve, such as flange valve, then PP-R pipe and valve connection should be flange connection. Connecting with the plastic pipe and flange can be used hot melt connection, flange can be used hemmed or band.(4) PE pipe, PB pipe and valve connection, method with PP-R tube.(5) the connection of PVC-C pipe, ABS pipe and valve, the way is the same as the PVC-U pipe.(6) PE-X pipe, PAP pipe, these two types of tubes, pipe specifications smaller, the pipe connection is card sleeve connection and compression connection, and the valve should be used to clamp or clamp sleeve transition joint.

- Q: Can plastic tubes be used for craft projects like DIY lamps?

- Yes, plastic tubes can definitely be used for craft projects like DIY lamps. They are versatile, lightweight, and easy to work with, making them ideal for creating unique and creative lamp designs. Additionally, plastic tubes come in various sizes and colors, allowing for endless possibilities and customization in your craft projects.

- Q: What's the little piece of plastic called?

- perhaps it is a cable protector ...

Send your message to us

Plastic Tubes - 2024 PPR Pipes for Industrial and Agricultural Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords