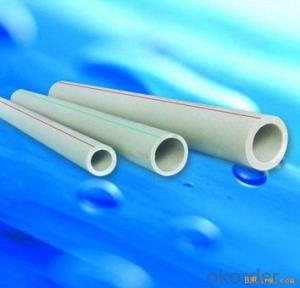

Plastic Tubes - 2024 New PPR Pipe for Industrial and Agricultural Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe

Application

1. Cold and hot water pipe system.

2. Potable drinking water system.

3. Air conditioning pipeline system.

4. Chemical industry pipelines system.

5. Indoor heating system, high temperature radiator heating system.

Feature

1) The professional factory of fittings.

2) The important manufacture of fittings in china.

3) High quality and better price.

4) Convenient One touch fittings provide instant tubing connections.

5) Elliptical release ring help to connect the tube easily by manual, no special tools required.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: How are plastic tubes recycled?

- Plastic tubes are typically recycled through a process that involves collection, sorting, shredding, melting, and reforming. First, the tubes are collected from various sources such as households or manufacturing facilities. Then, they are sorted based on their type of plastic and color. Next, the tubes are shredded into small pieces, known as flakes or granules. These flakes are then melted down and formed into pellets or beads. Finally, these pellets can be used as raw materials to produce new plastic products or even new plastic tubes, completing the recycling loop.

- Q: I already have a plastic water line with a on off switch coming up through the floor. I bought a new fridge and when they delivered it they said they could not install it because of the plastic tube- they said I had to change it- I've been to home depot etc and have no clue how to do it because everything else seems to be for the actual installation of a brand new line whereas in this case I need to know how to change the existing line. Any answers??

- You didn't say why it needs to be changed. If it takes a different size tubing, you will be running a new line. If the nut on the end of the tubing is not the correct one, you may be able to buy and install a new one. You would need to go to the parts section at HD. They have all types of connectors.

- Q: What industries use plastic tubes?

- There are several industries that use plastic tubes, including plumbing, construction, manufacturing, automotive, pharmaceutical, and food packaging industries.

- Q: Are plastic tubes resistant to freezing temperatures?

- Yes, plastic tubes are generally resistant to freezing temperatures.

- Q: How does transferring of liquid in a container to an empty container using a plastic tube works?

- You're talking about a siphon. You suck on the end to get the liquid up the tube and then down the other side, and all you need to do to keep it flowing is make sure the outside end of the tube is lower down than the inside end. The liquid pulls on itself, and there is more weight on the outer tube than the inner, so it's enough to draw the liquid up and down, as long as it ends up lower than it was before.

- Q: How do you measure the diameter of a plastic tube?

- To measure the diameter of a plastic tube, you can use a caliper or a ruler. Place the tube on a flat surface and use the caliper's jaws or the ruler to measure the distance from one edge of the tube to the opposite edge, ensuring that the measurement is taken at the widest point. This measurement will give you the diameter of the plastic tube.

- Q: Do plastic tubes have any limitations in terms of material compatibility?

- Yes, plastic tubes have limitations in terms of material compatibility. Some chemicals or substances can react with certain types of plastics, causing them to degrade, become brittle, or even dissolve. It is important to consider the chemical resistance of the plastic material when selecting a tube for specific applications to ensure it is compatible with the intended substances.

- Q: How are plastic tubes sealed to prevent leakage?

- Plastic tubes are typically sealed using various methods such as heat sealing, adhesive bonding, or crimping. Heat sealing involves melting the plastic ends together to create a secure bond. Adhesive bonding utilizes specialized adhesive materials to join the tube ends. Crimping involves applying pressure to deform and seal the tube ends using a crimping tool or machine. These sealing techniques help prevent leakage and ensure the contents of the plastic tubes remain intact.

- Q: How do you label plastic tubes?

- Plastic tubes can be labeled using various methods such as adhesive labels, heat shrink sleeves, direct printing, or laser etching, depending on the specific requirements and properties of the tubes.

- Q: i was blowing on a enclosed tube then i hear and feel a crackle between my ear and jaw and i felt like i knocked the stuffing out of my ear but i still hear perfectly normal and hear good. is something wrong and should i be concerned. my parents said it happened to them when they were little kids

- Your brains exploded.

Send your message to us

Plastic Tubes - 2024 New PPR Pipe for Industrial and Agricultural Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords