Plastic Sheets PVC Ceiling Celuka Foam Sheet for Furniture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Polyvinyl chloride (PVC) is a tough, strong thermoplastic material which has an excellent combination of physical and electrical properties. The products are usually characterized as plasticized or rigid types. Polyvinyl chloride (and co-polymers) is the second most commonly used polyvinyl resins in one of the most versatile plastics.

Product Features

•Excellent clarity, transparency and gloss

•Least thickness variation

•Non-toxic

•Smooth die-cutting

•Superior sealing and welding

•Excellent impact strength

•Higher processing yields

Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Details

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on |

3 | Thickness | 1~ 30mm |

4 | Density | 0.4~ 0.8g /cm 3 |

5 | Brand | CMAX |

6 | Certificate | SGS |

7 | Weldable | Yes |

8 | Foam Process | Cellular |

9 | Packing | Carton box or wooden pallet packing |

10 | production capability | 10000 pcs per month |

Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

FAQ

PVC foam board sheets foam board sign foam core board for shop discount

1.Q: Can you make design for us?

A: Yes, we offer custom service including sizes, printing, etc from our customers as long as they can provide available artwork to us.

2.Q: What are your company major products?

A: We have more than 10 years experience in producing cosmetic display,jewellery display,watch display,Menu holder,brochure holder,table organizer, gift and promotional items & many others acrylic products.

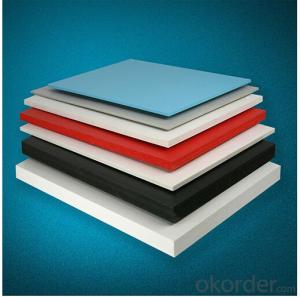

Pictures

- Q: Can plastic sheets be used for window glazing?

- Yes, plastic sheets can be used for window glazing.

- Q: Company wants me to pay extra for it but why do I need it?

- Probably because the factory demands it to keep your warranty, or it's code with your building department

- Q: Are plastic sheets resistant to chemicals used in industrial processes?

- Yes, plastic sheets are generally resistant to chemicals used in industrial processes.

- Q: I've been working with a lot of humanitarian help lately, and have noticed that most mediocre plastic sheeting (tarpaulin) is blue whereas the good stuff is white or white on one side and black on the other. Why is most plastic sheeting blue? Is there any particular reason for this choice in color?

- 1) Blue is a color that contrasts most other natural colors in it's surroundings such as green grass and brown dirt, and therefore is found easily for cleanup. 2) Out of the colors they could use, blue is the cheapest to produce. Black, and surprisingly even white, costs more than blue die. This is because most raw plastic is a gray or multiple colors, so it takes more bleach to make it white than it does to just color it blue. Plus the materials necessary to create blue die are cheaper than most other colors. 3) Blue does not absorb as much heat as some other colors would, and therefore will keep it's integrity longer.

- Q: Can plastic sheets be used for protective barriers against COVID-19?

- Yes, plastic sheets can be used as protective barriers against COVID-19. They can be installed as barriers in various settings such as retail stores, offices, and healthcare facilities to create a physical barrier that helps prevent the transmission of the virus through respiratory droplets.

- Q: Are plastic sheets resistant to fading from sunlight exposure?

- Yes, plastic sheets are generally resistant to fading from sunlight exposure.

- Q: i am using it to glue to the bottom on a skimboard so it rides smoother on the water

- I don't know if a plastic sheet would hold up to the pounding it would take. Maybe try an epoxy coating such as used on garage floors. Easy to apply, slick and smooth, very tough, and easy to repair if damaged.

- Q: If not, what kind of screws should I use?

- Yes, self tapping screws or sheet metal screws as you call them are fine for that type of work

- Q: Can plastic sheets be used for patio covers?

- Yes, plastic sheets can be used for patio covers. They are lightweight, durable, and can provide protection from rain and sun. However, it is important to choose high-quality plastic sheets that are specifically designed for outdoor use to ensure longevity and proper functionality.

- Q: Im looking for a place that sells sheets of Lenticular Len's. Its those plastic sheets that people use as decoders.

- I know a 3D lenticular lens sheet manufacturer,their quality is so good,the price is very competitve and delivery time is fast!

Send your message to us

Plastic Sheets PVC Ceiling Celuka Foam Sheet for Furniture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords