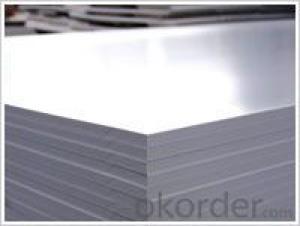

Plastic Sheets PVC Rigid Foam Board PVC Celuka Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Name | PVC Foam Board/Sheet |

Regular Size | 1220x2440mm, other sizes customized |

Thickness | 0.5mm~50mm |

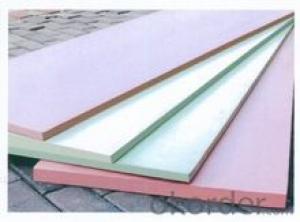

Color | White, Black as usual, Other color as request |

Density | 0.4g/cm3~1.5g/cm3 |

Common Type | PVC Free Foam 0.5mm ~ 50mm |

PVC Celuka Foam 8mm ~50mm | |

Application | a. Advertising, Digital Print, Carve Letters etc. materials |

b. Cabinets, Bathroom Cabinet, Kitchen Cabinet, Furniture etc. raw materials | |

c. Decoration Board, Display Board etc. | |

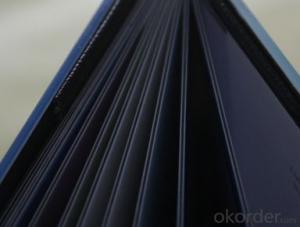

d. 1mm, 1.5mm thickness PVC Foam Sheets, use as Album, Menu Book, etc inside page material and so on |

Advantages

1.Light weight, easy to storing and transporting

2.Waterproof, fireproof and self-extinguishing, moisture-proof, soundproof and quakeproof

3.Good insulation

4.Good tenacity and high rigidity

5.No water absorption and sopping, no deformation

6.Easily to be processed

7.Good plasticity, being an excellent thermoform material

8.Smooth and clean surface, elegant vision

9.Anti-chemical corrosion, like acid, alkali and salt

10.Beautiful color retain long time, unfading and anti-aging

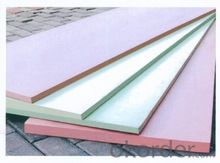

Detailed Images

PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

FAQ

(1) What colors do you have?

Any color and any design is available.

(2) Can you offer the sample?

Yes, the sample is free.and the courier fee is paid by customers.

Pictures

- Q: Are plastic sheets resistant to high-pressure applications?

- Yes, plastic sheets can be resistant to high-pressure applications depending on the specific type of plastic used and its thickness. Certain plastics, such as polycarbonate or acrylic, have excellent strength properties and can withstand high-pressure conditions without deforming or breaking. However, it is important to consider the specific requirements of the application and consult with manufacturers or experts to ensure the chosen plastic sheet is suitable for the intended high-pressure environment.

- Q: How thick are the PVC plates?

- Hardness: PVC plate has good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, are widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration industries.Product thickness: 0.8-30mm, product width: 1300mm 1500, mm parts processing: PVC processing parts, all Reed can be produced according to customer needs, can be hot bending, hot pressing, CNC, etc..PVC soft board: laminated sheet: 2-60mm product width: 1000mm * 2000 mm

- Q: Are plastic sheets resistant to cracking from vibrations?

- Plastic sheets can vary in their resistance to cracking from vibrations. Some types of plastic sheets, such as polycarbonate or acrylic, have good resistance to cracking and can withstand vibrations without cracking. However, other types of plastics may be more prone to cracking when subjected to vibrations. It ultimately depends on the specific type and quality of the plastic sheet being used.

- Q: Are plastic sheets suitable for outdoor furniture?

- Plastic sheets are generally suitable for outdoor furniture due to their durability, weather resistance, and ease of maintenance.

- Q: Are plastic sheets resistant to punctures?

- Yes, plastic sheets are generally resistant to punctures due to their durable and flexible nature. However, the level of puncture resistance can vary depending on the thickness and type of plastic used.

- Q: Are plastic sheets resistant to chemicals used in agriculture?

- Yes, plastic sheets are generally resistant to the chemicals used in agriculture. They provide a protective barrier against various agricultural chemicals, such as fertilizers, pesticides, and herbicides, ensuring that these chemicals do not seep into the soil or water sources.

- Q: How do plastic sheets compare to acrylic sheets?

- Plastic sheets and acrylic sheets have some similarities, as both are lightweight, durable, and versatile materials. However, acrylic sheets have several advantages over plastic sheets. Acrylic sheets are clearer, more transparent, and offer better optical clarity, making them an ideal choice for applications where visual aesthetics are crucial. Additionally, acrylic sheets have higher impact resistance, are more weather-resistant, and have better UV resistance compared to plastic sheets. Moreover, acrylic sheets can be easily molded, cut, and shaped, allowing for greater design flexibility. Overall, while plastic sheets may be cheaper, acrylic sheets provide superior quality and performance in various applications.

- Q: Are plastic sheets resistant to chemicals in swimming pool environments?

- Yes, plastic sheets are generally resistant to chemicals in swimming pool environments. They are commonly made from materials such as polyethylene or PVC, which have excellent chemical resistance properties. These plastics can withstand exposure to chlorine, bromine, and other pool chemicals without significantly degrading or corroding. However, it is important to note that prolonged exposure to certain harsh chemicals or extreme temperatures may still cause some deterioration or discoloration over time.

- Q: How do plastic sheets handle adhesive bonding?

- Plastic sheets generally handle adhesive bonding quite well. The smooth surface of plastic sheets allows for strong adhesion, and certain types of plastics can be specially treated to enhance their adhesive bonding properties. However, it is important to consider the specific type of plastic being used, as some plastics may require surface preparation or the use of specific adhesives to achieve optimal bonding.

- Q: These sheets should be non-transparent, pure white, 4-6mil in thickness, and relatively stiff (not like that used for plastic bags, but rather like mylar sheet).

- Most hobby shops should be able to supply you with this type of material. If they do not have it then they should be able to locate a supplier for you or at least get you a catalog that would allow you to purchase modeling materials. The link below is for a company that sells many plastic sheets and scaled plastic structural members for railroad models and that type of thing. Send for that catalog.

Send your message to us

Plastic Sheets PVC Rigid Foam Board PVC Celuka Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords