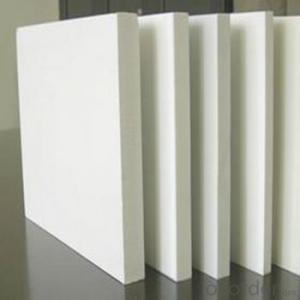

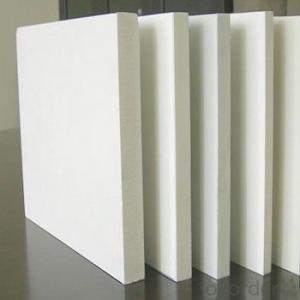

Plastic Sheets - Professional Custom Composite Price White Rigid Foam PVC Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

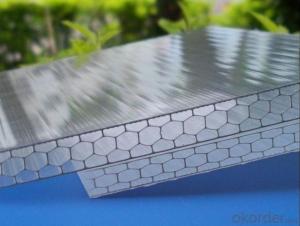

You Might Also Like

Specification

The main machines needed for PVC/ WPC foam board:

-PVC mixer

-PVC WPC foam board extrusion line

(Including autoloader, conical twin screw extruder, mould, calibration table, hauling machine, auto cutter- stacker)

- lamination machine(for furniture foam board)

- hot stamp printer (for furniture foam board)

- waste rusher& PVC miller

- Air compressor

- Water chiller

The popular model selected by our customers:

Popular Model | SJSZ80 |

Extruder | SJZ80/156 |

width | 1220mm |

thickness | 5-20mm(3-25mm) |

Max capacity(kg/h) | about 300 |

Advantage:

1. Waterproof, Moisture/Water resistant, less rotten, proven under salt water condition, UV-resistance

2. Fire retardant and self-extinguishing

3. Sound-insulated; Non-toxic

4. High recyclable, eco-friendly, saving forest resources

5. Weather resistant, suitable from minus -30 to 70 centigrade degree

6. Well done of Termites, insects, and moldy-proof

7. Easy to nail, hammered, drilled, sawed, turned, glued, bended, printed, oiled, thermoforming

8. Easy to clean

9. No any benzene and the formaldehyde discharge,Non-toxic

Product pics:

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities, they are mainly famous ,

such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

- Q: i want to take out my yugioh cards but im afraid i dont want them to lose their color they are all in sheets and im inside my house but the sun is coming from the windows so will they lose color? thanks 5 star automatic

- Don't place them near windows or take them out into direct sunlight. Make sure the sheets you use to cover them are opaque because if light penetrates the sheet they will be discoloured. Put them in a cloth or cardboard cover. That always works. Good luck!

- Q: What are the common uses of plastic sheets?

- Plastic sheets are commonly used for various purposes such as packaging materials, construction and building applications, signage, protective coverings, and even in the manufacturing of household items like shower curtains and storage containers.

- Q: Can plastic sheets be used for shower enclosures?

- Yes, plastic sheets can be used for shower enclosures. Plastic sheets, such as acrylic or polycarbonate, are commonly used as a cost-effective alternative to glass in shower enclosures. They offer durability, easy maintenance, and can be customized to fit different shower sizes and shapes.

- Q: Seems like no matter what I do I always seem to get blood on my sheets when on my period. How can I prevent this?

- Toss out several scoops of Kitty Litter.

- Q: What is the purpose of using plastic sheets?

- The purpose of using plastic sheets is to provide a protective barrier, insulation, or containment for various purposes, such as covering surfaces, protecting from weather elements, preventing dust or debris accumulation, or creating barriers for safety or privacy.

- Q: Are plastic sheets resistant to yellowing over time?

- No, plastic sheets are not completely resistant to yellowing over time.

- Q: Why does Dexter not get caught? He seems to make a lot of mistakes. e.g All the plastic sheets he uses?

- Omg I Know!! They never show him cleaning up the blood. what does he do with the plastic!

- Q: Do you actually know anyone who was scared into stockpiling plastic sheeting and duct tape?

- Right after Katrina and Rita went through the Houston area, alot of people stockpiled everything, water and sheeting and tape and batteries and canned food. Crazy heh

- Q: What are plastic sheets used for?

- Plastic sheets are used for various purposes such as packaging, construction, signage, protection, and even arts and crafts projects.

- Q: was at a party and was visiting with this couple and the conversation got about sex and the girl asked me if i had plastic sheets. i asked her why would anyone want plastic sheets? and she said if you don't know i'm not gonna tell you. now i'm curious.

- Because the dude might squirt mayonaise all over them and that wouldn't be good if they were normal sheets

Send your message to us

Plastic Sheets - Professional Custom Composite Price White Rigid Foam PVC Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords