Plastic Sheets - Cmax Embossed Polycarbonate Sheet for Showroom Applications

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

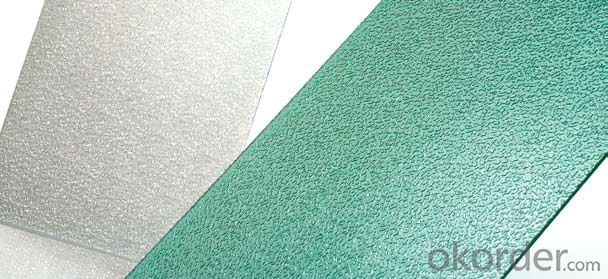

Features:

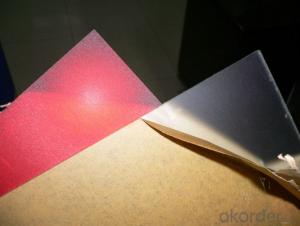

1. High light Transmisstion

2. Anti- Broken

3. Anti - Sunshine

4. UV protection

5. Easy Clean

6. Easy Installation

7. Long life Time (Up to 10 years under standard circumstance)

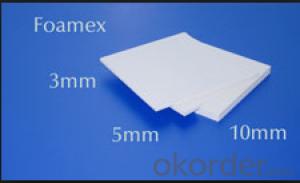

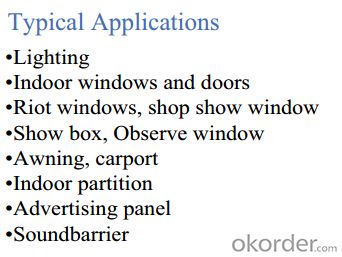

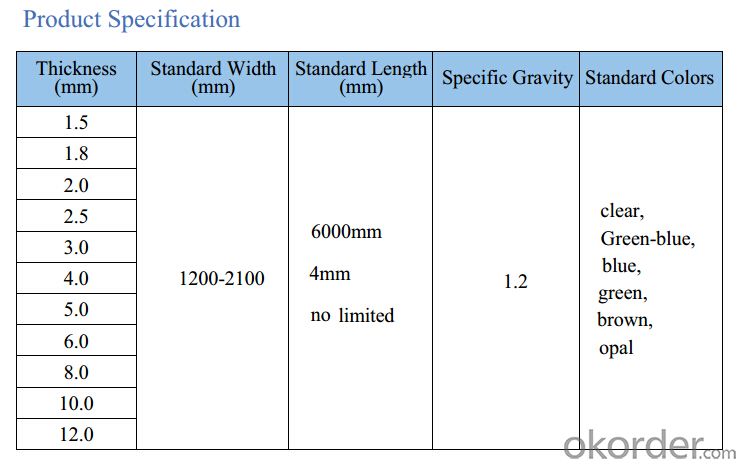

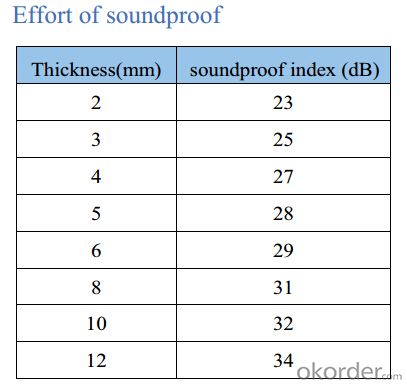

Specifications:

FAQ:

Where is your factory located?

Our production Base is located in Zhejiang Province. It is close to Ningbo Port, which is a main sea port of China,

What kinds of polycarbonate sheet can you supply?

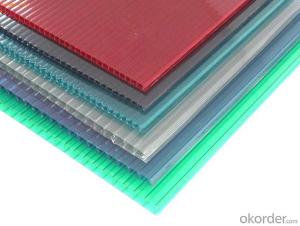

Our company has been in polycarbonate sheet business since 2004, until now, our products has covered hollow polycarbonate sheet, solid polycarbonate, embossed polycarbonate sheet and corrugated polycarbonate sheet.

How long life time does your product have?

Based on standard environment, we offer 10 years warranty for our 100% virgin material polycarbonate sheet, which is widely used in greenhouse, carport, swimming pool roof and so on.

- Q: also...what kind of glue would i need to glue it to the bottom of a skimboard?

- Polystyrene plastic is sold in sheet form at many hobby and model shops. Evergreen is the most common brand name - available from thicknesses of 0.005 and up - cost about $3-5 for a sheet 4 x 10. The glue you use depends on both materials being put together, and also the weather and forces that will be applied to it. If both are poly styrene an acetone-based solvent suchs as Testor's or Ambroid will dissolve the plastic and thus weld it together. If theyv are differnet materials - (what is a skimboard made from and where does it go?) - I would seek some advice form someone in that hobby.

- Q: Can plastic sheets be used as a barrier against moisture?

- Yes, plastic sheets can be used as a barrier against moisture. They are commonly used as vapor barriers in construction and packaging materials to prevent the passage of water vapor and protect against moisture damage.

- Q: With what glue can you stick glass and plastic board firmly?

- AB glue can make glass and plastic plate firmly stick.

- Q: Can plastic sheets be used in food packaging?

- Yes, plastic sheets can be used in food packaging.

- Q: Are plastic sheets resistant to staining from cleaning agents?

- Yes, plastic sheets are generally resistant to staining from cleaning agents.

- Q: Why is tarm paper or plastic sheeting put under hardwood floors?

- They are basically used as a vapor barrier to reduce the expansion/contraction of the floor. Tar paper will also cushion and quiet the floor just a little bit.

- Q: Are acrylic plastic sheets flexible and cuttable?

- I worked with 1/8 Plexiglas, and I cut it with my scroll saw. I needed to use ultra-fine saw teeth to do the job. Two problems happened. First, when the saw blade was set at too high a speed, it melted the Plexiglas. This also happened if I did not move the Plexiglas fast enough. I had to have the top vibration clamp fairly close to the Plexiglas to stop it from jumping up. Before I realized this was necessary, I split 2 pieces. My project was see through drawer fronts for merchandise display. I had to predrill the holes for the screws to mount the fronts into the wood sides. I used masking tape on the area that was to be drilled to protect the Plexiglas surface. I still had breakage. Next time I do a project of this type, I will use thicker acrylic.

- Q: Would you please help me find clear, acetate sheets that are heat resistant and thick enough to be a card rather than just overlay a card?

- Definitely an art / craft supply shop would be a good starting point. Alternatively, you could try and research on the internet to find a shop which sells what you are seeking.

- Q: I took plastics and wood shop in highschool and it was a long time ago. Recently i had a project that involved using plastic but i dont know where i can get it. Anyone know where i can get sheets of colored plastic?

- personally ive never seen sheets of plastic sold before an i go to the craft store alot. theres acrylic an resins maybe you can make your own? i dunno if regular plastics if you can maybe melt them an form it into a sheet? i never tried it , but my first thought would be colored resin or acrylics an pouring it so it becomes a thing sheet

- Q: Can You Pay Someone At Home Depot To Cut A Sheet Of Plexiglass Into A Certain Shape Once You've Bought It?

- Call home depot and ask

Send your message to us

Plastic Sheets - Cmax Embossed Polycarbonate Sheet for Showroom Applications

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords