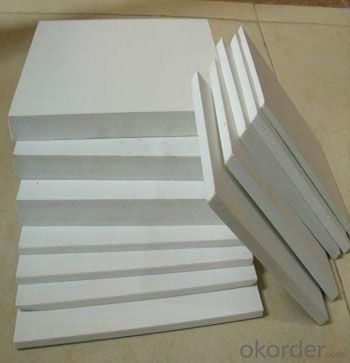

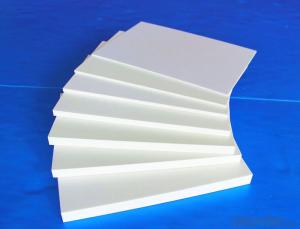

Plastic Sheets - Bright White Foam PVC/Forrex PVC Foam Sheet Supplier

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

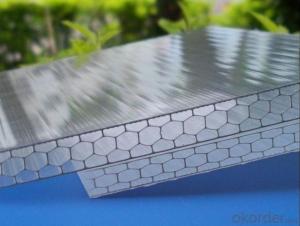

Specification

Product Description

Weldable/Bendable - suitable for fabrication

UV Resistant - Black only

Physiologically inert - approved for food applications (Natural only)

Electrical insulation - it is a good insulator

Weatherproof - it doesn't absorb water

Chemical resistance - resists corrosive chemicals (e.g. Sulphuric Acid, Caustic Soda)

| Basic information | ||

| Product name | High density PVC sheet | |

| Polyvinyl chloride sheet | ||

| Item NO. | CPL-PVC | |

| Country of origin | Guangdong China | |

| Brand | ChinaPlas | |

| Optional type | Sheet,Film,Rod,Tube | |

| Material | Virgin PVC resin | |

| Grade | Grade A | |

| H.S code | 3920430090 | |

| Certificate | SGS,Rosh | |

| Environment | Recyclable | |

| Sample | For free, but customer pays the freight. | |

| Similar products | PP sheet,PE sheet,UPVC sheet | |

| Specification | ||

| Density | 1.55-1.6 g/cm3 | |

| Colour | Natural(gery),blue, other colors can be customized | |

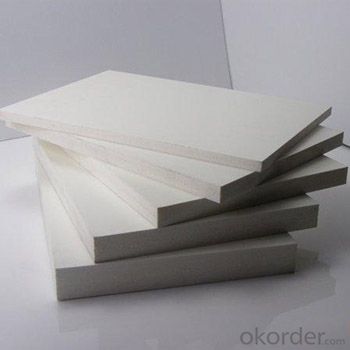

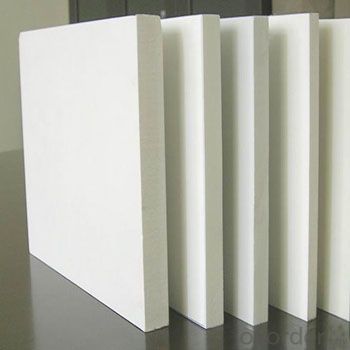

| Sheets Thickness | 2.0-50mm | |

| Stock Size | 1220×2440mm,1000×2000mm,can be customized | |

| Stock Size (Length) | 1000mm,can be customized | |

| Tubes outer diameter | Can be customized | |

| Size | ||

| Formation methods | Extrude or lamination | |

| Delivery details | ||

| Stock | 40Ton | |

| Packaging | 1. Wooden pallet with carton. | |

| 2. Plastic pallet with carton. | ||

| 3. Wooden wooden pallet with wooden case. | ||

| 4. According to customer requirements. | ||

| Delivery | 1. Stock size 3-5 working days. | |

| 2. Custom size 8-15 working days. | ||

| Attribute parameter | ||

| Flame test | V -0 , can be self-extinguishing | |

| Impact strength | planar ≥8kJ/m2 side ≥8kJ/m2 | |

| Tensile strength | Transverse ≥40MPa Vertical ≥40MPa | |

| Heat size change rate | Transverse ± 3 % Vertical ± 5% | |

| Property | ||

| 1. Excellent anti-tearing | ||

| 2. Insulating property is good | ||

| 3. Fire retardant, with self-extinguishing | ||

| 4. Degree of hardness is big, the intensity is high | ||

| 5. The surface is smooth,easy welding and machining | ||

| 6. Good chemical stability,acid,alkali,corrosion-resistant | ||

| 7. Against ultraviolet ray, bears the aging, does not absorb water | ||

Our services

1. We offer samples for free, buyer only need to pay express fee, if you make a order from us finally, we will subtract the express fee from total amount

2. Through Alibaba Trade Assurance finish the order, we will give additional 1% discount

3. Trial order can be accepted

4. If you need, welcome to visit our factory and examine cargo

- Q: I am looking for something in rolls or very big sheets. It has to be thin about like that of a milk jug give or take a bit. I saw some school folders that are now made out of plastic that are about the right thickness. White or clearish are the best color. Got any ideas?

- Where To Buy Plastic Sheets

- Q: Ok i have a large entertainment center that was custom built and one of my 2 young girls has damaged the existing plastic mesh inserts that go inside the bottom doors. They are thin black plastic about 2 foot by 2 foot each, with many little holes (like a mesh) for the sound of the speakers to come through. I have looked all over the web for a simular material but havent had any luck finding anything. I dont care if i have to buy raw material that i have to paint or cut. I would just like to know if anyone knows where to find a material like this?

- in a home store, there's a product at the 'window screen' area.... it's called pet screen... it's black plastic mesh.... I use it in my pond, too!....all kinds of uses!!... besides screen, that is.... works good that way, too!

- Q: What are the thermal expansion properties of plastic sheets?

- The thermal expansion properties of plastic sheets vary depending on the type of plastic used. Generally, plastics have a higher coefficient of thermal expansion compared to metals, meaning they expand more when heated and contract more when cooled. This property can be utilized in applications such as thermal insulation or in manufacturing processes where tight tolerances are not critical.

- Q: Acrylic plate and plastic plate how to distinguish?

- Acrylic is also called PMMA, plastic sheet belongs to engineering plastics; PVC is polyvinyl chloride, and it is a general plastic. Acrylic is the best new material that can be used to produce sanitary ware after ceramic. As a special plexiglass, acrylic can also be used in aircraft windshield, and used in harsh environments for decades.

- Q: I'm quite tired of writing in a notebook and having the pages underneath hold the impression of what I wrote. I've seen these this plastic sheets that stop it but I'm not sure what they would be called. Any ideas?--Andriana

- Just take the underneath pages out...

- Q: I just bought a pickup truck, and it has this large 4'x8' plastic sheet in the back. Its about an inch thick, and weighs a LOT. It has nothing to do with a bed liner or anything. It seems to be extremely durable, from being in the back of a work truck for over 10 years its just got some scratches. Does anyone know what it could be used for? I want to try and sell it, but I have absolutely no idea what its purpose is, so I dont know how to even list it! One of my friends suggested it may be used for flooring or something, but i have no idea. I could see it being cut up and used for bench tops or something of that sort, but again, no clue. Any ideas?

- It probably was used as a bed liner, the rest of us just use a sheet of plywood and this guy had access to the plastic sheeting, so used that instead

- Q: We have had a problem with bug bites, and we're pretty curtain that its bed bugs, not mosquitos...I'm curious if those plastic sheets are good for that!

- Bed okorder / Hope this helps matador 89

- Q: Put drops of water on glass or plastic sheet. After evaporation we see white soft dust there. What's that?

- If it was pure water, and there was no dust present in the room there should be no dust. But if it's tap water that is most likely lime deposits or deposits from the minerals in the water. Try the same experiment with distilled water (not bottled drinking water, because minerals are added).

- Q: Can plastic sheets be used for machine guarding?

- Yes, plastic sheets can be used for machine guarding. They are commonly used as a protective barrier to prevent operators from coming into direct contact with moving parts or hazardous areas of machinery. Plastic sheets offer visibility, durability, and can be customized to fit specific machine guarding requirements.

- Q: Are plastic sheets easy to install?

- Yes, plastic sheets are generally easy to install. They are lightweight and flexible, making them simple to handle and position. Additionally, they often come with pre-drilled holes or adhesive backing, which further simplifies the installation process.

Send your message to us

Plastic Sheets - Bright White Foam PVC/Forrex PVC Foam Sheet Supplier

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords