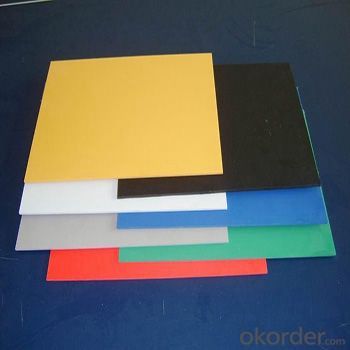

Plastic Sheets - PVC Foam Sheet Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

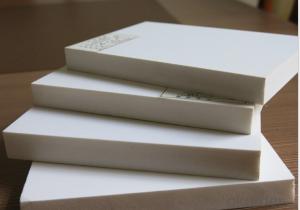

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware.

The PVC foam board is made through foaming and pressing into shape with additive.

It is widely used in Sanitaryware, Building material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Sanitarywares, kitchen cabinet, washroom cabinet.

5.Advertisment

6.Contruction

FAQ

Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

NOTE: we can make other size according customer requirment

Payment | L/C,T/T,Western Union, MoneyGram, Paypal |

MOQ | 50PCS |

Delivery | 6-10days after confirm your order |

- Q: Are plastic sheets resistant to scratching?

- Yes, plastic sheets are generally resistant to scratching. However, the level of resistance can vary depending on the type and quality of the plastic used.

- Q: Can plastic sheets be glued together?

- Yes, plastic sheets can be glued together using various methods such as solvent-based adhesives, epoxy, or even heat welding. The choice of adhesive will depend on the type of plastic being used.

- Q: Are plastic sheets resistant to bending during transportation?

- Yes, plastic sheets are generally resistant to bending during transportation due to their flexible and durable nature. However, the specific resistance to bending may vary depending on the thickness and type of plastic used.

- Q: How do I remove the double adhesive on the plastic board?

- On the hard surface of the self-adhesive mark, we can use non greasy nail polish water on the surface of the object, and then gently wipe with soft cloth. Tiles and glass can be easily removed with gasoline. Wood, paint, furniture, etc., can not use gasoline, can only use hot water or electric hair dryer, slowly erase after heating.

- Q: Are plastic sheets resistant to fading from sunlight exposure?

- Yes, plastic sheets are generally resistant to fading from sunlight exposure.

- Q: Are plastic sheets resistant to UV degradation?

- Yes, plastic sheets can be resistant to UV degradation depending on the type of plastic used and the specific formulation. Some plastics, like polycarbonate and acrylic, are inherently resistant to UV radiation and have additives that enhance their UV stability. However, not all plastic sheets are UV resistant, so it is important to check the product specifications or consult with the manufacturer to ensure the desired level of UV resistance.

- Q: What are the different surface treatments available for plastic sheets?

- There are several different surface treatments available for plastic sheets, including but not limited to: 1. Coating: A thin layer of material is applied to the surface of the plastic sheet to enhance its appearance, durability, or specific properties such as UV resistance, scratch resistance, or chemical resistance. 2. Printing: Various printing techniques can be used to apply designs, patterns, or logos onto the plastic sheet, including screen printing, digital printing, or pad printing. 3. Lamination: A layer of protective film or material is bonded to the surface of the plastic sheet to provide additional protection against scratches, abrasion, or chemicals. 4. Embossing: A pattern or texture is pressed into the surface of the plastic sheet to create a three-dimensional effect or improve grip. 5. Polishing: The surface of the plastic sheet is mechanically or chemically polished to enhance clarity, smoothness, and transparency. 6. Etching: A chemical or laser etching process is used to create designs, text, or patterns by removing or altering the surface of the plastic sheet. These surface treatments can be chosen based on the desired aesthetic, functional, or protective properties required for the specific application of the plastic sheet.

- Q: Can plastic sheets be used for food trays or containers?

- Yes, plastic sheets can be used for food trays or containers.

- Q: How do you clean plastic sheets?

- To clean plastic sheets, you can start by wiping them down with a damp cloth or sponge using mild soap or a gentle household cleaner. Avoid using abrasive materials or harsh chemicals that could damage the plastic. Rinse off the soap residue thoroughly and then dry the sheets with a clean cloth or allow them to air dry.

- Q: Are plastic sheets scratch-resistant?

- Yes, plastic sheets can be scratch-resistant depending on the type of plastic used and any additional coatings or treatments applied to the surface.

Send your message to us

Plastic Sheets - PVC Foam Sheet Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords