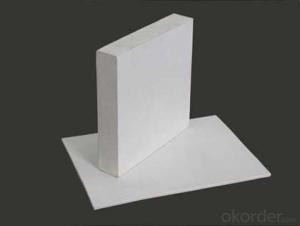

Plastic Sheets - 2024 PVC Expansion Sheet and Hard PVC Expansion Sheet for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

PVC foam board is a new particularly lightweight, closed cell substrate board material for printing and mounting jobs. The distinguishing feature of PVC boards are the bright white, uniform surfaces. This is an undispensable feature when it comes to digital printing. PVC foam board is divided into two groups. One is PVC free foam board, and another is celluka foam board.

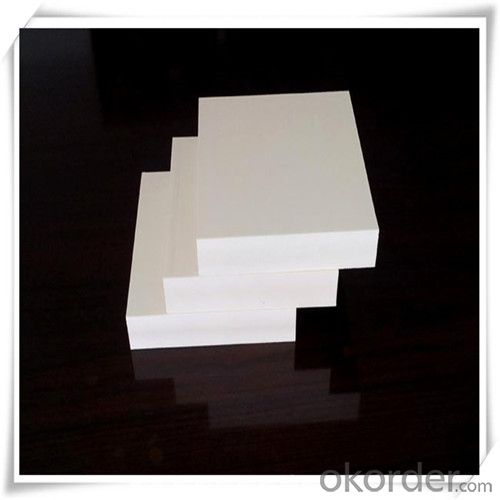

Product Specification:

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43mm-0.9mm

Advantage:

• Not easy to heat conduction

• No need to paint. Easy to maintain.

• Saving energy.

• Can be recycled and reused

• Be beautiful and fashionable decoration.

• Not contain lead. Protecting the environment.

• Be anti-moisture, water-proof.

• Be firm and durable and anti- rotten.

• Having high quality and stable chemical character.

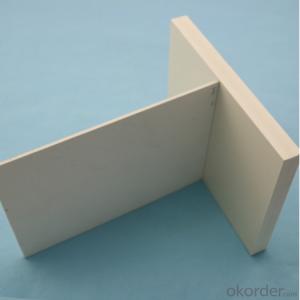

The difference between PVC free foam board and crust foam board:

PVC crust foam board is a kind of PVC foam boards we recommended to our customers as they have superior quality. The extrusion line adopts celuka foam technology. These processes result in a "skinning" or outer layer of the foam board and

harder or more scratch resistant. Compared with other PVC foam board, this kind of PVC foam board not only has much

more smooth surface, but also has the more skin hardness, and the mechanical performance of the PVC celuka foam board is much better than other PVC foam boards.

PVC Foam Sheet Pictures:

FAQ:

Q: Are we a factory manufacturer or a trade company?And What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q: Could you provide samples?

A: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

Q: Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

.

- Q: Are plastic sheets resistant to chemicals used in pools?

- Yes, plastic sheets are typically resistant to chemicals used in pools.

- Q: Can plastic sheets be used for automotive applications?

- Yes, plastic sheets can be used for automotive applications. They are commonly used for creating interior and exterior parts such as dashboards, door panels, and body panels. Plastic sheets offer advantages such as being lightweight, durable, and resistant to corrosion, making them suitable for automotive use.

- Q: I would like to use 2 past recycle plastic sheet and make tent or any other materialwhich can be sold in the market .

- yes what about kites. a good kids or grown ups enjoyment

- Q: I want to insulate my floor in my house if i do so do i put up a plastic sheeting after i put in the insulate?

- The plastic sheeting serves as a vapor barrier, and is needed only if your house is in a region where outside temperatures drop below freezing. The principle is that air inside of the house has moisture--from your breathing, from cooking, from the bathroom, and from your humidifier. Without the vapor barrier, the moisture will get into your insulation, which has a temperature gradient with the inside surface at room temperature and the outside surface below freezing. At some point within the insulation the moisture will freeze and ice will accumulate. This not only reduces the effectiveness of the insulation, but makes for a large problem in the spring when the ice melts. You can see that the vapor barrier should be against the inside wall, so that moisture can't get in the insulation. If you insulate your floor, the vapor barrier must go up. That is why it is best to use faced insulation, with the face up. Don't use plastic sheeting in conjunction with faced insulation, as moisture can get trapped between the two.

- Q: I need a piece of flat sturdy plastic about 1/8 thick. Does anybody know where I can buy this? I dont want plexiglass, its too expensive.

- You okorder / okorder / GOOD LUCK !!

- Q: i have to figure out the price of ONE overheadd projector plastic sheet for school, so how many of these plastic sheets are in a pack ??? please help !!

- Staples sells them in packs of 100 for the write on kind for $37 The kind you can use in a printer in packs of 50 for $40 So I guess the write on kind = 37 cents each ink jet kind = 80 cents each

- Q: Can plastic sheets be used for manufacturing equipment?

- Yes, plastic sheets can be used for manufacturing equipment. Plastic sheets are often used in various industries for manufacturing equipment due to their versatility, durability, and ease of fabrication. They can be customized to suit specific equipment requirements, provide corrosion resistance, and are lightweight compared to other materials. Additionally, plastic sheets offer cost-effective solutions and are commonly used in applications such as machinery guards, conveyor systems, and equipment enclosures.

- Q: Can plastic sheets be used for air conditioning ducts?

- Yes, plastic sheets can be used for air conditioning ducts. Plastic ductwork, such as PVC or flexible plastic, is commonly used in residential and commercial buildings for air conditioning systems. These plastic sheets offer various benefits such as flexibility, corrosion resistance, and ease of installation. However, it is important to ensure that the plastic sheets used meet the required standards and regulations for air conditioning ducts to ensure safe and efficient operation.

- Q: Are plastic sheets resistant to oil and grease?

- Yes, plastic sheets are generally resistant to oil and grease.

- Q: Are plastic sheets resistant to staining from food dyes?

- Yes, plastic sheets are generally resistant to staining from food dyes.

Send your message to us

Plastic Sheets - 2024 PVC Expansion Sheet and Hard PVC Expansion Sheet for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords